A metal spatula provides excellent heat resistance and durability, making it ideal for scraping and stirring caramel as it thickens without melting or warping. An offset spatula offers precision and control but is typically better suited for delicate tasks rather than the high heat and heavy stirring involved in caramelizing. Choosing a metal spatula ensures efficient caramelization with minimal risk of damage to your tools or uneven cooking.

Table of Comparison

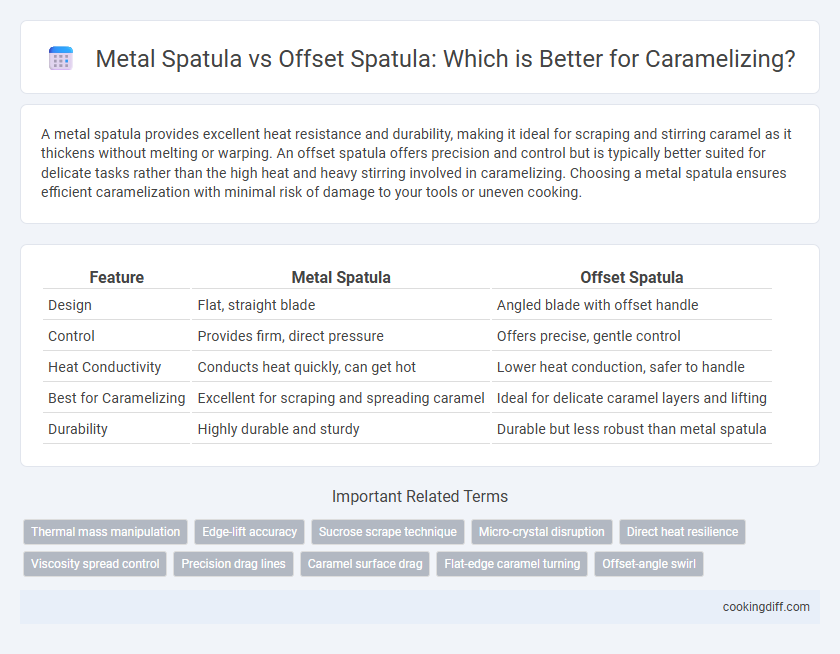

| Feature | Metal Spatula | Offset Spatula |

|---|---|---|

| Design | Flat, straight blade | Angled blade with offset handle |

| Control | Provides firm, direct pressure | Offers precise, gentle control |

| Heat Conductivity | Conducts heat quickly, can get hot | Lower heat conduction, safer to handle |

| Best for Caramelizing | Excellent for scraping and spreading caramel | Ideal for delicate caramel layers and lifting |

| Durability | Highly durable and sturdy | Durable but less robust than metal spatula |

Introduction to Caramelizing: Tools Matter

Choosing the right spatula is crucial for effective caramelizing, as different materials impact heat distribution and precision. Metal spatulas and offset spatulas each offer unique advantages suited to specific caramelizing techniques.

- Metal spatula - Provides excellent heat resistance and durability, ideal for scraping and flipping caramelized ingredients without melting.

- Offset spatula - Features an angled blade for precise control and delicate handling, perfect for drizzling or smoothing caramel.

- Tool selection - Using the appropriate spatula enhances caramelization results by optimizing heat exposure and minimizing ingredient damage.

Metal Spatula: Features and Benefits

Metal spatulas offer superior heat resistance, making them ideal for caramelizing as they can withstand high temperatures without melting or warping. Their rigid, flat blades allow precise scraping and flipping, ensuring even caramelization and preventing burning. Metal spatulas provide excellent durability and ease of cleaning, enhancing efficiency in caramelizing processes.

Offset Spatula: Key Characteristics

The offset spatula features a thin, flexible blade with a slight bend, allowing precise control when spreading or flipping delicate caramelized items. Its ergonomic design keeps hands clear of hot surfaces, enhancing safety during caramelization processes. The spatula's narrow profile ensures even heat distribution and smooth movement, making it ideal for delicate sugar work and precise layering.

Heat Resistance: Metal vs Offset Spatulas

Metal spatulas offer superior heat resistance, making them ideal for caramelizing as they can withstand high temperatures without melting or warping. Offset spatulas, typically made with plastic or silicone handles, are less heat-resistant and may deform or release harmful substances when exposed to intense heat.

When caramelizing sugar or sauces on a hot surface, using a metal spatula ensures safe handling and precise stirring without risk of damage. Offset spatulas provide better control in delicate tasks but are less suitable for high-heat applications. Prioritizing metal spatulas enhances durability and performance during caramelization processes in professional and home kitchens.

Control and Precision During Caramelizing

| Metal spatula | Provides sturdy control and excellent precision when scraping or flipping caramelized sugar due to its rigid structure and flat edge. |

| Offset spatula | Offers enhanced maneuverability and delicate handling around caramelized edges, allowing for refined precision without disturbing the sugary layer. |

| Control and precision comparison | Metal spatulas excel at heavy-duty scraping tasks, enabling strong leverage, whereas offset spatulas deliver finer control for detailed caramelizing work on uneven surfaces. |

Durability and Maintenance of Each Spatula

Metal spatulas offer superior durability for caramelizing tasks, resisting warping and heat damage over time. Offset spatulas require more careful maintenance to preserve their angled design and delicate blade.

- Durability of Metal Spatulas - Constructed from solid stainless steel, metal spatulas withstand high temperatures and frequent use without bending.

- Maintenance of Metal Spatulas - These spatulas are dishwasher safe and easy to clean, minimizing rust risks with proper drying.

- Maintenance of Offset Spatulas - The angled blade demands gentle handwashing to prevent damage and maintain its precise shape for effective caramelizing.

Surface Compatibility: Protecting Cookware

Which spatula offers better surface compatibility for caramelizing without damaging cookware? A metal spatula is effective but may scratch non-stick or delicate surfaces, risking cookware degradation. Offset spatulas, with their angled and often softer edges, provide safer contact, preserving the integrity of pans during caramelization.

Ideal Tasks for Each Spatula in Caramelization

Metal spatulas are perfect for scraping and flipping caramelized ingredients due to their sturdy, flat edge. Offset spatulas excel in spreading and smoothing caramel layers evenly because of their angled design.

- Metal spatula for scraping - Ideal for loosening sticky caramel from pans without damaging the surface.

- Metal spatula for flipping - Provides leverage to easily flip thick caramelized items like seared fruits or nuts.

- Offset spatula for spreading - Allows precise, even distribution of caramel over desserts or confections.

Choosing the correct spatula enhances control and prevents breaking or uneven caramel surfaces.

Expert Opinions: Chef Preferences

Expert chefs often prefer metal spatulas for caramelizing due to their durability and ability to scrape the pan effectively without melting. Metal spatulas provide precise control for evenly browning sugars and achieving the perfect caramel texture.

Offset spatulas, favored by pastry chefs, offer finesse in handling delicate caramel layers and spreading evenly while avoiding burning. Their angled design allows for safer maneuvering around hot pans, making them ideal for detailed caramel work.

Related Important Terms

Thermal mass manipulation

Metal spatulas with higher thermal mass retain and transfer heat more effectively, promoting even caramelization by maintaining consistent surface temperature. Offset spatulas, with lower thermal mass, cool rapidly and may disrupt the caramelization process due to uneven heat distribution.

Edge-lift accuracy

A metal spatula's rigid, sharp edge enhances precision in edge-lift accuracy when caramelizing, allowing for clean separation of delicate caramel layers without breaking. In contrast, an offset spatula's flexible blade offers less control in lifting edges, increasing the risk of uneven caramel transfer and fragmentation.

Sucrose scrape technique

A metal spatula provides the necessary rigidity and sharp edge to efficiently scrape and manipulate caramelized sucrose without bending, allowing for precise control during the caramelizing process. In contrast, an offset spatula's flexible blade may lack the firmness required for effective sucrose scraping, making it less ideal for achieving clean, even caramelization surfaces.

Micro-crystal disruption

Using a metal spatula for caramelizing effectively disrupts micro-crystals in sugar due to its rigid, flat edge, promoting even melting and preventing grainy textures. An offset spatula, with its angled and flexible blade, offers less direct pressure, making it less efficient at breaking down sugar crystals during caramelization.

Direct heat resilience

Metal spatulas exhibit superior direct heat resilience compared to offset spatulas, making them ideal for caramelizing tasks requiring constant contact with high temperatures. Their durable stainless steel construction resists warping and melting, ensuring precise control and efficiency during the caramelization process.

Viscosity spread control

A metal spatula offers superior control over viscosity and spread during caramelizing, thanks to its rigid, thin edge that evenly distributes thick mixtures without bending. In contrast, an offset spatula, with its angled flexible blade, provides less precision in managing caramel's consistency, making it less ideal for handling viscous caramel spreads.

Precision drag lines

Using a metal spatula for caramelizing allows for precise drag lines due to its rigid, flat edge that evenly distributes pressure while shaping the caramel. An offset spatula offers less control for detail work, as its bent handle and flexible blade can create uneven lines and disrupt delicate caramel patterns.

Caramel surface drag

Using a metal spatula with a flat, stiff edge provides better control and reduces scraping damage on the caramel surface, ensuring an even caramelization without unwanted surface drag. In contrast, an offset spatula, with its angled design and flexible blade, tends to create uneven drag on the caramel surface, potentially causing streaks and disrupting the smooth caramel layer.

Flat-edge caramel turning

A metal spatula with a flat edge provides precise control and even pressure when turning caramel, preventing breakage and ensuring smooth, uniform caramelization. Unlike offset spatulas, the flat-edge design facilitates clean lifting and flipping of delicate caramel sheets without bending or splintering.

Metal spatula vs offset spatula for caramelizing. Infographic

cookingdiff.com

cookingdiff.com