Caramelizing involves heating sugar directly in a pan until it melts and turns golden brown, developing rich, complex flavors through Maillard reactions and sugar breakdown. Cold caramelization, however, occurs slowly at room temperature or below, where sugar molecules rearrange without heat, producing different flavor profiles and textures. Understanding these contrasting processes helps chefs control the sweetness intensity and texture in desserts and confections.

Table of Comparison

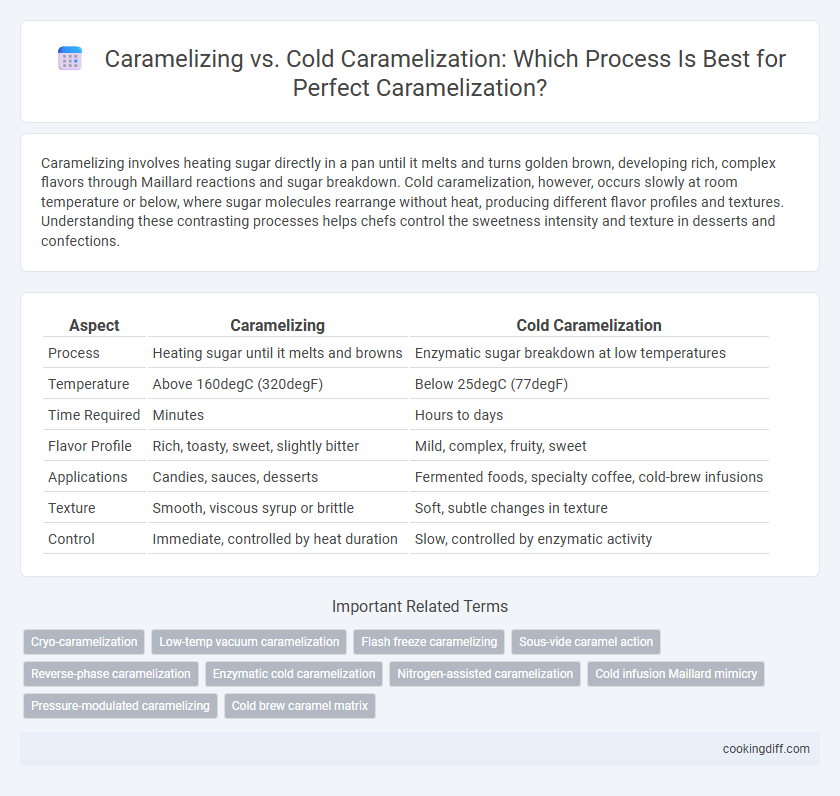

| Aspect | Caramelizing | Cold Caramelization |

|---|---|---|

| Process | Heating sugar until it melts and browns | Enzymatic sugar breakdown at low temperatures |

| Temperature | Above 160degC (320degF) | Below 25degC (77degF) |

| Time Required | Minutes | Hours to days |

| Flavor Profile | Rich, toasty, sweet, slightly bitter | Mild, complex, fruity, sweet |

| Applications | Candies, sauces, desserts | Fermented foods, specialty coffee, cold-brew infusions |

| Texture | Smooth, viscous syrup or brittle | Soft, subtle changes in texture |

| Control | Immediate, controlled by heat duration | Slow, controlled by enzymatic activity |

Understanding Caramelization: Traditional vs Cold Techniques

Caramelizing involves heating sugar to high temperatures, typically around 340degF (170degC), to develop rich, complex flavors and a deep amber color. Cold caramelization, a less common technique, relies on enzymatic reactions at lower temperatures to gradually break down sugars without direct heat, preserving subtle taste notes. Understanding these methods highlights how traditional heat caramelization intensifies sweetness and bitterness, while cold caramelization emphasizes delicate, nuanced flavors in culinary applications.

The Science Behind Caramelization Processes

Caramelization is a complex chemical process where sugar molecules break down under high heat, typically above 320degF (160degC), resulting in a rich, nutty flavor and brown color. Cold caramelization, in contrast, involves enzymatic reactions at lower temperatures, where enzymes like invertase convert sucrose into simpler sugars without the high heat typically causing color change or deep flavor development. Understanding the molecular transformations and temperature dependencies in both processes is essential for culinary applications and food science innovations.

Key Differences: Caramelizing vs Cold Caramelization

Caramelizing involves heating sugar until it melts and browns, creating deep flavors through thermal transformation. Cold caramelization refers to enzymatic processes that break down sugars at lower temperatures without heat application.

- Temperature - Caramelizing requires high heat, whereas cold caramelization occurs at ambient temperatures.

- Process type - Caramelizing is a chemical reaction driven by heat, cold caramelization relies on enzymes for sugar breakdown.

- Flavor profile - Caramelizing produces rich, nutty flavors; cold caramelization results in milder, fruity notes.

Benefits of Classic Heat Caramelization

Classic heat caramelization enhances flavor depth by breaking down sugars at high temperatures, creating rich, complex taste profiles essential in desserts and savory dishes. The process intensifies aroma and color due to the Maillard reaction, leading to appealing sensory qualities in caramelized foods.

Heat caramelization offers precise control over the browning process, ensuring consistent texture and sweetness levels. This method also promotes quicker sugar transformation compared to cold caramelization, improving efficiency in culinary applications.

Advantages of Cold Caramelization Methods

Cold caramelization methods preserve the natural flavors and nutrients of sugars by avoiding high heat, resulting in a cleaner and more precise caramel taste. This process reduces the risk of burning and creates a smoother texture compared to traditional caramelizing techniques.

Cold caramelization offers enhanced control over the reaction speed, allowing for consistent and repeatable results in food preparation. It minimizes the formation of bitter compounds and preserves delicate aromatic profiles, making it ideal for gourmet applications. Furthermore, this method improves the nutritional profile by retaining more antioxidants and reducing harmful byproducts.

Flavor Profiles: Traditional vs Cold Caramelization

How do flavor profiles differ between traditional caramelizing and cold caramelization? Traditional caramelizing uses heat to develop deep, rich, and nutty flavors through the Maillard reaction, creating complex aromatic compounds. Cold caramelization preserves more fruity and floral notes by avoiding high temperatures, resulting in a lighter and more delicate flavor profile.

Equipment Needed for Each Caramelization Technique

Caramelizing requires precise heat control and typically involves stovetop or oven equipment to achieve the desired Maillard reaction. Cold caramelization uses enzymatic processes and often necessitates specialized refrigerated or controlled-temperature setups to develop sweetness without heat.

- Heat Source - Stovetop burners or ovens provide consistent high temperatures needed for traditional caramelizing.

- Temperature Control - Thermostats and temperature probes ensure exact heat application for even caramel development.

- Refrigeration Units - Cold caramelization depends on refrigeration or incubators to maintain enzyme activity at low temperatures.

Choosing between equipment depends on the desired caramelization method and the type of sweetness transformation required.

Caramelization Process Step-by-Step: Heat vs Cold

Caramelization involves heating sugar to around 340degF (170degC), initiating a complex Maillard reaction that produces rich, nutty flavors and a deep amber color. This heat-driven process breaks down sugar molecules, resulting in distinct caramel notes used in baking and confectionery.

Cold caramelization, by contrast, relies on enzymatic reactions at lower temperatures, typically using invertase enzymes to gradually transform sucrose into glucose and fructose without heat. This method preserves delicate aromas while creating subtle sweetness and a smoother texture in desserts.

Best Foods for Each Type of Caramelization

Caramelizing heats sugars to develop deep, rich flavors ideal for vegetables like onions and carrots. Cold caramelization uses enzymatic processes without heat, perfect for fruits such as apples and bananas to enhance natural sweetness.

- Best for Hot Caramelization - Onions, carrots, and sweet potatoes develop complex flavors through direct heat caramelizing.

- Best for Cold Caramelization - Apples, bananas, and pears utilize enzymatic caramelization to naturally sweeten without altering texture.

- Suitable crossover foods - Pineapples and peaches can be enhanced by either method depending on desired texture and flavor intensity.

Related Important Terms

Cryo-caramelization

Cryo-caramelization, also known as cold caramelization, involves enzymatic breakdown at low temperatures, preserving fresh fruit flavors and enhancing natural sugars without the high heat used in traditional caramelizing. This process results in intensified sweetness, complex flavor profiles, and improved texture, making it ideal for applications requiring subtle caramel notes while maintaining freshness.

Low-temp vacuum caramelization

Low-temp vacuum caramelization uses reduced pressure to lower the caramelization temperature, preserving delicate flavors and preventing burnt notes common in traditional high-heat caramelizing processes. This method enhances the depth of caramel flavor while maintaining the integrity of heat-sensitive ingredients, resulting in a smoother, richer caramel profile.

Flash freeze caramelizing

Flash freeze caramelizing rapidly crystallizes sugar by exposing it to extreme cold, preserving delicate flavors and preventing overcooking common in traditional caramelizing methods. Unlike slow caramelization that relies on heat to brown sugar gradually, flash freeze caramelizing enhances texture and flavor profiles through instant cooling, making it ideal for sensitive culinary applications.

Sous-vide caramel action

Caramelizing through traditional heat exposure initiates Maillard reactions and sugar breakdown, resulting in richer, complex flavors, while cold caramelization via sous-vide maintains precise temperature control to gradually develop sweeter, more nuanced caramel notes without burning. Sous-vide caramel action enhances flavor depth by promoting even sugar caramelization at lower temperatures, preserving moisture and texture often lost in conventional high-heat caramelizing methods.

Reverse-phase caramelization

Reverse-phase caramelization uses lower temperatures and longer cooking times to achieve a deeper, more controlled Maillard reaction, enhancing flavor complexity compared to traditional high-heat caramelizing. This method prevents burning and preserves caramel's subtle aromatic compounds, making it ideal for delicate applications in gourmet cooking.

Enzymatic cold caramelization

Enzymatic cold caramelization, unlike traditional caramelizing which relies on high heat to induce Maillard reactions and sugar browning, uses enzymes such as invertase or glucose oxidase to break down sugars at low temperatures, preserving delicate flavors and nutrients. This process enhances sweetness and aroma without thermal degradation, making it ideal for flavor development in sensitive food products like dairy and fruits.

Nitrogen-assisted caramelization

Nitrogen-assisted caramelization enhances the caramelizing process by using an inert nitrogen atmosphere to control oxidation and improve flavor development compared to traditional caramelizing, which relies on high heat and air exposure. This cold caramelization technique enables precise temperature regulation and minimizes bitterness, resulting in a smoother, richer caramel profile while preserving key nutritional compounds.

Cold infusion Maillard mimicry

Cold caramelization, or cold infusion Maillard mimicry, replicates traditional caramelizing flavors without heat by facilitating Maillard reactions at lower temperatures, preserving delicate aromas and nutritional content. Unlike conventional caramelizing, which relies on high heat to break down sugars and proteins, cold caramelization uses enzymatic or chemical catalysts to achieve similar browning and flavor complexity while minimizing thermal degradation.

Pressure-modulated caramelizing

Pressure-modulated caramelizing enhances the Maillard reaction by controlling temperature and moisture levels, resulting in richer flavor development and uniform browning compared to traditional cold caramelization techniques. This process accelerates sugar breakdown under elevated pressure, optimizing caramel color and texture in industrial food applications.

Caramelizing vs Cold Caramelization for process. Infographic

cookingdiff.com

cookingdiff.com