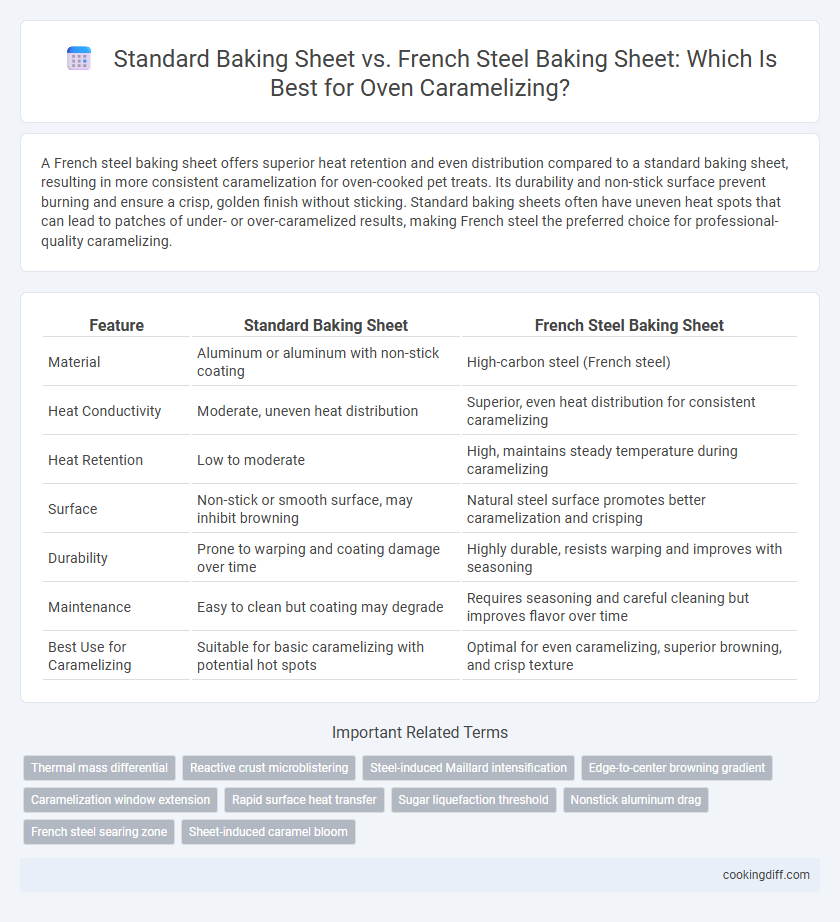

A French steel baking sheet offers superior heat retention and even distribution compared to a standard baking sheet, resulting in more consistent caramelization for oven-cooked pet treats. Its durability and non-stick surface prevent burning and ensure a crisp, golden finish without sticking. Standard baking sheets often have uneven heat spots that can lead to patches of under- or over-caramelized results, making French steel the preferred choice for professional-quality caramelizing.

Table of Comparison

| Feature | Standard Baking Sheet | French Steel Baking Sheet |

|---|---|---|

| Material | Aluminum or aluminum with non-stick coating | High-carbon steel (French steel) |

| Heat Conductivity | Moderate, uneven heat distribution | Superior, even heat distribution for consistent caramelizing |

| Heat Retention | Low to moderate | High, maintains steady temperature during caramelizing |

| Surface | Non-stick or smooth surface, may inhibit browning | Natural steel surface promotes better caramelization and crisping |

| Durability | Prone to warping and coating damage over time | Highly durable, resists warping and improves with seasoning |

| Maintenance | Easy to clean but coating may degrade | Requires seasoning and careful cleaning but improves flavor over time |

| Best Use for Caramelizing | Suitable for basic caramelizing with potential hot spots | Optimal for even caramelizing, superior browning, and crisp texture |

Introduction to Oven Caramelizing

Oven caramelizing involves applying dry heat to sugar-rich foods to develop a deep, complex flavor and golden-brown color. Choosing the right baking sheet significantly influences heat distribution and caramelization quality.

- Standard baking sheet - Typically made of aluminum with a nonstick coating, offering moderate heat conduction and even caramelization.

- French steel baking sheet - Constructed from heavy-gauge steel, providing superior heat retention and more consistent caramelization results.

- Heat responsiveness - French steel sheets heat up slower but maintain steady temperatures, enhancing control over the caramelizing process.

Selecting a French steel baking sheet can yield more uniform caramelization compared to standard baking sheets.

What Is a Standard Baking Sheet?

A standard baking sheet is typically made from aluminum or aluminized steel, offering even heat distribution for consistent caramelizing results. Its lightweight design makes it easy to handle, but it may warp under high temperatures commonly used in caramelizing processes. Standard baking sheets usually have a thin gauge, which can result in less crisp edges compared to thicker options like French steel baking sheets.

Overview of French Steel Baking Sheets

French steel baking sheets offer superior heat retention and even heat distribution essential for precise caramelizing in ovens. Their robust construction reduces warping and promotes uniform browning compared to standard baking sheets.

- Material Quality - French steel sheets are crafted from low-carbon steel, enhancing durability and heat conductivity.

- Heat Performance - These sheets maintain consistent temperatures, preventing hot spots that can cause uneven caramelization.

- Maintenance - Unlike non-stick standard sheets, French steel requires seasoning to build a natural, long-lasting non-stick surface.

Heat Distribution: Standard vs. French Steel

Standard baking sheets, typically made from aluminum or aluminum alloys, offer even heat distribution but can develop hot spots that affect caramelization consistency. French steel baking sheets are crafted from thicker, high-quality steel, providing superior heat retention and more uniform temperature across the surface, which enhances the caramelizing process. This consistent heat distribution reduces the risk of burning and promotes a more even browning, essential for achieving optimal caramelization results.

Caramelization Results Compared

| Type of Baking Sheet | Heat Conductivity | Caramelization Quality | Cook Time Consistency |

|---|---|---|---|

| Standard Baking Sheet | Moderate | Uneven caramelization; prone to hotspots causing inconsistent browning | Variable; longer cook times required due to less efficient heat transfer |

| French Steel Baking Sheet | High | Even caramelization with rich, uniform browning; enhances flavor depth | Consistent; shorter cook times due to superior heat retention and distribution |

Durability and Longevity

French steel baking sheets offer superior durability compared to standard baking sheets, resisting warping and corrosion over extended use. Their robust construction ensures consistent heat distribution, which maintains performance during oven caramelizing.

Standard baking sheets are typically made from thinner metal, making them more prone to bending and surface damage over time. In contrast, French steel baking sheets withstand high temperatures and frequent use without degrading. This longevity makes French steel sheets a cost-effective choice for frequent caramelizing tasks.

Ease of Cleaning and Maintenance

French steel baking sheets offer superior durability and resistance to staining, making them easier to clean after caramelizing compared to standard baking sheets, which often retain sticky residues. Maintenance of French steel pans typically involves simple wiping and occasional seasoning, while standard sheets may require intensive scrubbing or soaking to remove caramelized sugars.

- French steel baking sheets resist staining - Their non-porous, high-grade steel surface prevents caramel from sticking and discoloring.

- Standard baking sheets retain sticky residue - Aluminum or coated surfaces can trap caramel, complicating cleaning.

- French steel requires minimal maintenance - Occasional seasoning minimizes rust and simplifies cleanup compared to frequent scrubbing needed for standard sheets.

Cooking Versatility and Applications

Which baking sheet offers greater cooking versatility for oven caramelizing, a standard baking sheet or a French steel baking sheet? Standard baking sheets are typically lightweight and provide even heat distribution, ideal for general caramelizing tasks like roasting vegetables or fruits. French steel baking sheets, crafted from carbon steel, offer superior heat conductivity and durability, making them perfect for achieving precise caramelization and baking applications requiring consistent high heat.

Cost and Value Considerations

Standard baking sheets are generally more affordable, making them a cost-effective choice for occasional caramelizing tasks. They offer sufficient heat distribution but may lack the durability and precise temperature control needed for perfect caramelization.

French steel baking sheets come at a higher upfront cost but provide exceptional heat conduction and long-lasting performance. This investment often results in more consistent caramelized textures and better value for frequent home bakers or professionals.

Related Important Terms

Thermal mass differential

French steel baking sheets have a significantly higher thermal mass compared to standard baking sheets, allowing them to maintain steady, even heat during oven caramelizing. This results in more consistent browning and reduced risk of burning caramel due to rapid temperature fluctuations.

Reactive crust microblistering

French steel baking sheets promote superior reactive crust microblistering during oven caramelizing due to their excellent heat conductivity and even temperature distribution, enhancing Maillard reactions. Standard baking sheets often lack the thermal consistency necessary for optimal caramelized crust formation, resulting in less pronounced microblistering and uneven browning.

Steel-induced Maillard intensification

French steel baking sheets promote superior caramelizing by enhancing the Maillard reaction through efficient heat conduction and retention, resulting in deeper browning and intensified flavor development compared to standard aluminum or non-stick baking sheets. The steel's high thermal mass ensures even surface temperatures that accelerate sugar and amino acid reactions, critical for achieving optimal caramelization in oven applications.

Edge-to-center browning gradient

A French steel baking sheet offers superior heat conduction compared to a standard baking sheet, resulting in a more uniform edge-to-center browning gradient during oven caramelizing. This enhanced thermal responsiveness minimizes hot spots, ensuring even caramelization and consistent texture across the entire surface.

Caramelization window extension

French steel baking sheets extend the caramelization window by providing superior heat retention and even heat distribution compared to standard baking sheets, resulting in more consistent browning and enhanced Maillard reactions. Their higher thermal conductivity minimizes hot spots, allowing sugars to caramelize gradually and uniformly without burning, optimizing flavor and texture development.

Rapid surface heat transfer

French steel baking sheets provide rapid surface heat transfer due to their high thermal conductivity, enabling even and quick caramelization of sugars and surfaces. Standard baking sheets, often made from aluminum or aluminized steel, typically have slower heat transfer rates, which can result in less consistent caramelization and longer cooking times.

Sugar liquefaction threshold

French steel baking sheets conduct heat more efficiently than standard baking sheets, reaching higher temperatures faster, which affects the sugar liquefaction threshold during caramelizing. This precise temperature control helps achieve optimal caramelization without burning, as sugar typically liquefies around 320degF (160degC), a level more consistently maintained by French steel surfaces.

Nonstick aluminum drag

A French steel baking sheet offers superior heat conductivity and even caramelization compared to a standard nonstick aluminum baking sheet, which can suffer from drag and uneven cooking due to its lower thermal responsiveness. The dense steel surface promotes better browning and reduces sticking during oven caramelizing, making it ideal for consistent, caramel-rich results.

French steel searing zone

French steel baking sheets feature a searing zone that promotes even heat distribution and rapid caramelization by maintaining higher surface temperatures compared to standard baking sheets. This enhanced thermal conductivity accelerates the Maillard reaction, producing richer, deeper caramelized flavors on oven-cooked foods.

Standard baking sheet vs French steel baking sheet for oven caramelizing. Infographic

cookingdiff.com

cookingdiff.com