Caramelizing transforms sugar by heating it until it melts and darkens, creating a rich, complex flavor and a smooth, glossy texture that enhances desserts. Cold-pressed sugar retains its granular form and natural nutrients, offering a coarser texture and subtle sweetness without the deep caramel notes. Choosing caramelized sugar results in a velvety, melt-in-your-mouth finish, while cold-pressed sugar provides a crunchier bite and less intense flavor.

Table of Comparison

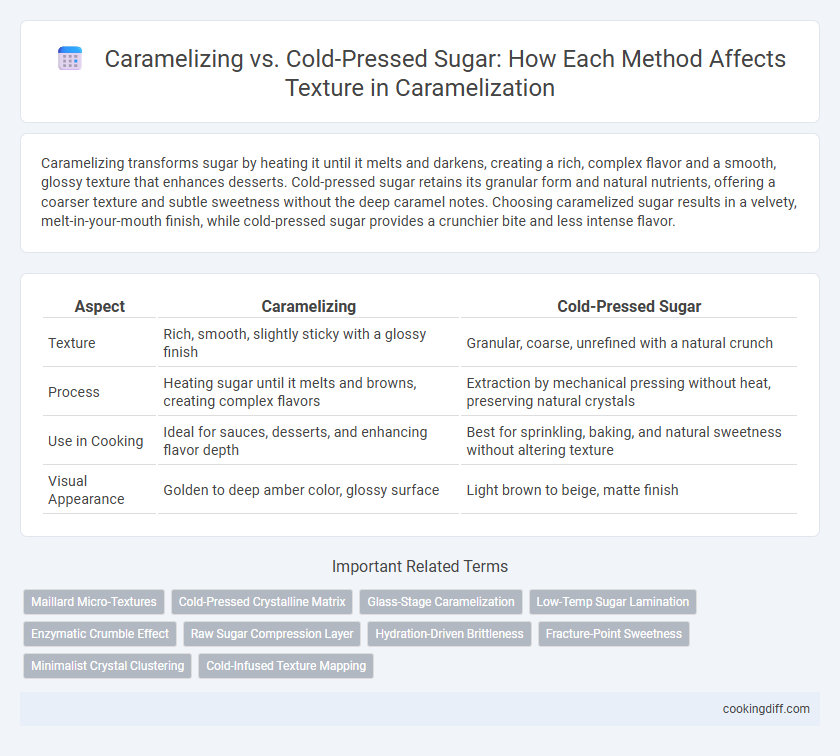

| Aspect | Caramelizing | Cold-Pressed Sugar |

|---|---|---|

| Texture | Rich, smooth, slightly sticky with a glossy finish | Granular, coarse, unrefined with a natural crunch |

| Process | Heating sugar until it melts and browns, creating complex flavors | Extraction by mechanical pressing without heat, preserving natural crystals |

| Use in Cooking | Ideal for sauces, desserts, and enhancing flavor depth | Best for sprinkling, baking, and natural sweetness without altering texture |

| Visual Appearance | Golden to deep amber color, glossy surface | Light brown to beige, matte finish |

Understanding Caramelizing and Cold-Pressed Sugar

Caramelizing transforms sugar through heat, creating a rich, complex flavor and a smooth, glossy texture. Cold-pressed sugar retains its granular structure, offering a crunchier texture and less depth of flavor.

- Caramelizing - Involves heating sugar until it melts and browns, producing a silky, velvety texture ideal for sauces and desserts.

- Cold-Pressed Sugar - Extracted without heat, preserving natural crystals that provide a coarse texture and mild sweetness.

- Texture Difference - Caramelized sugar delivers a soft, chewy consistency, while cold-pressed sugar maintains a firm, granular bite.

Understanding these differences helps chefs select the appropriate sugar form to achieve desired texture and flavor profiles in recipes.

The Science Behind Caramelization

Caramelizing involves heating sugar until it undergoes a complex series of thermal decomposition reactions, producing rich flavors and a browned color. This process enhances texture by creating a crisp, brittle structure unlike the granulated nature of cold-pressed sugar.

The science behind caramelization centers on the breakdown of sucrose molecules at temperatures above 320degF (160degC), generating hundreds of flavor compounds and changing the sugar's physical state. Cold-pressed sugar retains its granular form because it is processed at low temperatures, preserving its original crystalline structure. In contrast, caramelization transforms sugars into a smooth, glass-like texture that contributes to the unique mouthfeel in caramelized dishes and confections.

What Is Cold-Pressed Sugar?

Cold-pressed sugar is made by mechanically extracting juice from sugarcane without heat, preserving its natural molasses content and resulting in a coarser texture. Unlike caramelizing, which involves heating sugar to develop complex flavors and a smooth texture, cold-pressed sugar retains a raw, granular consistency ideal for toppings.

- Cold-Pressed Sugar Production - Extracted through a mechanical process that avoids heat, maintaining natural molasses and nutrients.

- Texture Difference - Retains a coarse and gritty texture compared to the smooth and glossy finish achieved by caramelizing sugar.

- Use in Recipes - Preferred for adding crunch and natural sweetness without altering the texture through heat.

Texture Differences: Caramelizing vs Cold-Pressed Sugar

Caramelizing sugar produces a rich, smooth texture with a glossy finish, creating a crisp outer layer that enhances the sensory experience of desserts. This process involves heating sugar until it melts and browns, resulting in a complex flavor profile and a firm, brittle consistency.

Cold-pressed sugar retains a granular texture, preserving the sugar's natural crystalline structure without melting or caramelizing. This method offers a coarser mouthfeel and a more subtle sweetness, ideal for recipes requiring a crunchy texture rather than a smooth one.

How Cooking Methods Impact Sugar Texture

Caramelizing sugar involves heating it until it melts and browns, resulting in a smooth, rich texture with complex flavors and slight crispness when cooled. Cold-pressed sugar retains its granular form and moisture, producing a coarser, more crystalline texture without the deep caramel notes from heat. These distinct cooking methods directly influence the final texture, with caramelizing creating a soft, buttery consistency, while cold-pressed preserves crunch and raw sweetness.

Flavor Profiles: Caramelized vs Cold-Pressed Sugar

Caramelizing sugar transforms its flavor profile by creating complex, rich, and deep caramel notes that enhance desserts with a buttery sweetness and slight bitterness. Cold-pressed sugar retains a more natural, raw sweetness and granular texture, offering bright and clean sugar tones without the depth found in caramelization.

- Caramelized Sugar Flavor - Develops rich, nutty, and slightly bitter notes through heat-induced Maillard reactions.

- Cold-Pressed Sugar Flavor - Maintains a pure, clean sweetness with subtle molasses undertones from minimal processing.

- Texture Contrast - Caramelizing melts sugar into a smooth, sticky matrix, whereas cold-pressed sugar remains coarse and granular.

Best Uses for Caramelized Sugar Based on Texture

Caramelized sugar offers a rich, crunchy texture ideal for desserts like creme brulee and caramel tarts where a crisp topping is desired. Cold-pressed sugar retains a finer, grainy texture suited for sprinkling on baked goods or sweetening beverages without altering mouthfeel. Using caramelized sugar enhances depth and complexity, while cold-pressed sugar ensures subtle sweetness and smooth texture in recipes.

Cold-Pressed Sugar in Modern Culinary Applications

Cold-pressed sugar retains more natural molasses and nutrients compared to traditional refined sugars, offering a richer flavor profile and unique texture in modern culinary applications. It creates a slightly coarse, granular texture that enhances mouthfeel in desserts and beverages.

Unlike caramelizing, which produces a smooth, buttery texture through heating, cold-pressed sugar maintains its crystalline structure, making it ideal for toppings and garnishes. Chefs use cold-pressed sugar to add complexity and crunch without altering the moisture content of dishes.

Choosing the Right Sugar Technique for Desired Texture

| Caramelizing Sugar | Involves heating sugar until it melts and turns golden brown, creating a rich, crisp texture with deep complexity. Ideal for desserts needing a brittle or crunchy finish like caramel sauces or brittle toppings. Offers enhanced flavor development due to Maillard reaction and sugar browning. |

| Cold-Pressed Sugar | Maintains granular structure without heat processing, resulting in a fine texture with natural sweetness. Suitable for recipes where a soft, grainy consistency or subtle sweetness is desired, such as in cold beverages or delicate pastries. Retains more natural molasses content and nutrients compared to caramelized sugar. |

| Choosing the Right Technique | Selection depends on desired texture and flavor profile; caramelizing offers a crisp, rich texture with complex flavor, while cold-pressed sugar yields a softer, granulated texture with pure sweetness. Consider the final mouthfeel and cooking method when determining which sugar technique to employ. |

Related Important Terms

Maillard Micro-Textures

Caramelizing sugar creates Maillard micro-textures that enhance the surface crispness and depth of flavor, producing a complex, crunchy exterior ideal for desserts. Cold-pressed sugar retains larger granules, resulting in coarser textures with less browning and a milder taste profile, lacking the rich caramelized notes from Maillard reactions.

Cold-Pressed Crystalline Matrix

Cold-pressed sugar retains a distinct crystalline matrix that preserves a crunchy texture, making it ideal for applications requiring a crisp bite, unlike caramelizing which transforms sugar into a smooth, viscous caramel with a soft, sticky texture. The cold-pressed crystalline structure provides enhanced texture stability in baked goods and confections, offering a unique mouthfeel that caramelized sugar lacks.

Glass-Stage Caramelization

Glass-stage caramelization occurs at 300-310degF (149-154degC), where sugar transforms into a hard, brittle texture ideal for glossy caramel coatings and crunchy candy shells. Cold-pressed sugar, lacking high heat exposure, retains granulated texture without the smooth, glass-like finish achieved through precise temperature control during caramelization.

Low-Temp Sugar Lamination

Low-temp sugar lamination during caramelizing creates a smooth, glossy texture with enhanced depth and complexity compared to cold-pressed sugar, which often remains grainy and lacks uniformity. Precise temperature control in low-temp caramelizing ensures sugar crystals dissolve evenly, resulting in a tender, velvety mouthfeel ideal for confections and desserts.

Enzymatic Crumble Effect

Caramelizing sugar involves heating it until it melts and browns, creating a rich, smooth texture with subtle bitterness essential for desserts, whereas cold-pressed sugar maintains raw granules that produce a distinct enzymatic crumble effect characterized by its granular, slightly enzymatic texture. The enzymatic crumble effect from cold-pressed sugar results from residual enzymes breaking down complex carbohydrates, enhancing textural contrast and complexity in pastries compared to the homogenous texture of caramelized sugar.

Raw Sugar Compression Layer

Caramelizing raw sugar creates a distinct compressed layer that enhances texture by forming a crunchy, golden crust, whereas cold-pressed sugar maintains a softer, more granular consistency without melting. The caramelization process intensifies flavor complexity and adds a robust, chewy contrast compared to the delicate crispness from cold-pressed sugar.

Hydration-Driven Brittleness

Caramelizing transforms sugar through heat, creating a brittle texture by driving off moisture and promoting a glass-like structure, unlike cold-pressed sugar which retains higher hydration levels resulting in a softer, less brittle consistency. The hydration-driven brittleness in caramelized sugar is critical for achieving crisp textures in confections, whereas cold-pressed sugar's moisture content leads to chewiness and reduced snap.

Fracture-Point Sweetness

Caramelizing sugar involves heating it until it reaches a fracture-point where the texture becomes crisp and brittle, creating a rich, deep sweetness with complex flavor notes. In contrast, cold-pressed sugar retains its granular texture and pure sweetness without the caramelized crunch, offering a more straightforward sweet taste without textural contrast.

Minimalist Crystal Clustering

Caramelizing sugar transforms it through controlled heat, promoting minimalist crystal clustering that results in a smooth, glossy texture ideal for sauces and desserts. Cold-pressed sugar retains larger, irregular crystals, yielding a coarser mouthfeel and less consistent texture compared to the refined caramelized form.

Caramelizing vs Cold-Pressed Sugar for texture. Infographic

cookingdiff.com

cookingdiff.com