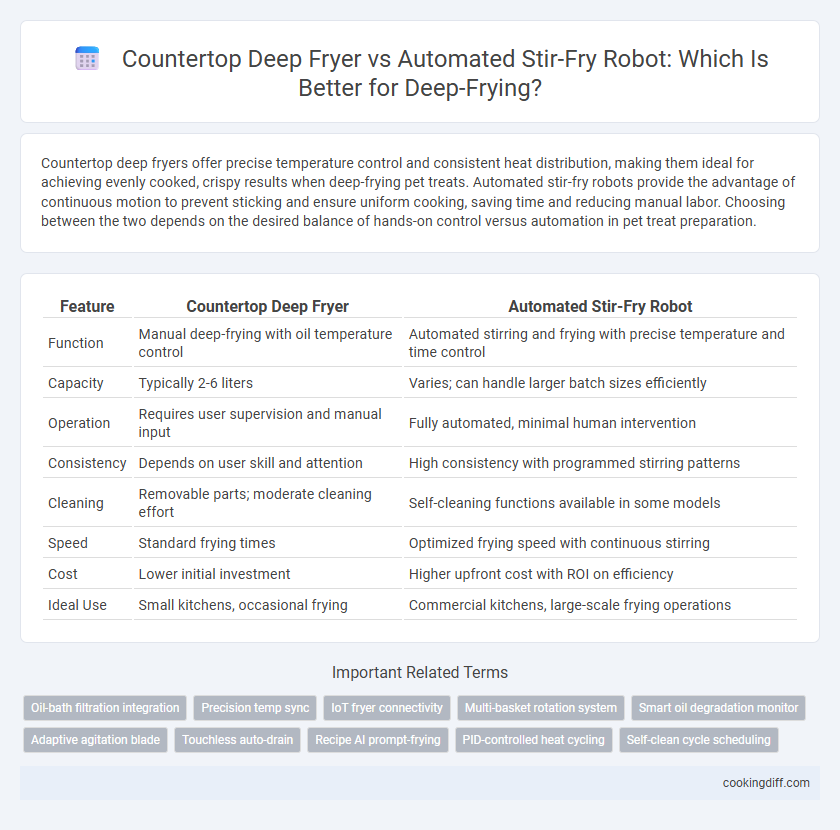

Countertop deep fryers offer precise temperature control and consistent heat distribution, making them ideal for achieving evenly cooked, crispy results when deep-frying pet treats. Automated stir-fry robots provide the advantage of continuous motion to prevent sticking and ensure uniform cooking, saving time and reducing manual labor. Choosing between the two depends on the desired balance of hands-on control versus automation in pet treat preparation.

Table of Comparison

| Feature | Countertop Deep Fryer | Automated Stir-Fry Robot |

|---|---|---|

| Function | Manual deep-frying with oil temperature control | Automated stirring and frying with precise temperature and time control |

| Capacity | Typically 2-6 liters | Varies; can handle larger batch sizes efficiently |

| Operation | Requires user supervision and manual input | Fully automated, minimal human intervention |

| Consistency | Depends on user skill and attention | High consistency with programmed stirring patterns |

| Cleaning | Removable parts; moderate cleaning effort | Self-cleaning functions available in some models |

| Speed | Standard frying times | Optimized frying speed with continuous stirring |

| Cost | Lower initial investment | Higher upfront cost with ROI on efficiency |

| Ideal Use | Small kitchens, occasional frying | Commercial kitchens, large-scale frying operations |

Introduction: Modern Deep-Frying Solutions Compared

Which modern solution offers greater efficiency for deep-frying: countertop deep fryers or automated stir-fry robots? Countertop deep fryers provide precise temperature control and compact design ideal for small to medium-scale operations. Automated stir-fry robots combine deep-frying capabilities with continuous stirring, optimizing cooking uniformity and reducing labor costs in high-volume environments.

Overview: Countertop Deep Fryer Basics

Countertop deep fryers offer a compact, manually operated solution designed for precise temperature control and quick frying tasks in small kitchens. They typically feature adjustable thermostats and removable oil vats for easy cleaning and maintenance.

- Compact Design - Small footprint suitable for limited counter space in homes or small restaurants.

- Manual Operation - Users adjust temperature and frying times, allowing for customized frying results.

- Easy Maintenance - Removable oil containers and lids simplify cleaning and oil replacement.

Countertop deep fryers serve as practical, user-friendly appliances for controlled deep-frying without requiring complex automation.

Overview: Automated Stir-Fry Robot Deep-Frying Capabilities

The automated stir-fry robot offers precise temperature control and consistent frying times, ensuring uniform deep-frying results. Equipped with advanced sensors and programmable settings, it can adapt to various ingredients and frying styles with minimal human intervention. This technology enhances kitchen efficiency by reducing labor and maintaining high-quality output compared to traditional countertop deep fryers.

Deep-Frying Performance and Consistency

Countertop deep fryers provide excellent heat control and can reach high temperatures quickly, ensuring crispy and evenly cooked food with consistent results. They allow manual adjustments to maintain oil quality and frying times, which is crucial for achieving optimal deep-frying performance.

Automated stir-fry robots offer precision and repeatability by using programmed cycles to maintain consistent heat distribution and agitation, reducing the risk of uneven cooking. These machines enhance deep-frying consistency by minimizing human error and delivering uniform texture and flavor across batches.

Capacity and Batch Size Comparison

Countertop deep fryers typically offer smaller capacity, handling batches of up to 4 liters, suitable for home or small-scale use. Automated stir-fry robots can manage larger batch sizes exceeding 10 liters, optimized for commercial deep-frying with consistent quality.

- Countertop Deep Fryer Capacity - Generally ranges from 2 to 5 liters, ideal for limited batch frying.

- Automated Stir-Fry Robot Capacity - Supports batch sizes of over 10 liters for high-volume cooking.

- Batch Size Efficiency - Automated robots maintain uniform frying quality across larger batches, unlike smaller fryers which may require multiple cycles.

Ease of Use and Automation Features

Countertop deep fryers offer straightforward operation with manual temperature control and easy oil drainage, making them suitable for users preferring hands-on cooking. Their simplicity ensures quick setup but requires constant attention during frying to prevent overcooking.

Automated stir-fry robots integrate advanced automation features such as precise temperature regulation and programmed frying cycles, significantly reducing user intervention. These machines provide consistent cooking results and improve efficiency in commercial kitchens through intelligent monitoring and timely stirring.

Safety and Risk Management

Countertop deep fryers require constant human supervision to manage oil temperature and avoid hazards such as oil splashes and fire risks, making safety protocols critical. Automated stir-fry robots incorporate advanced sensors and automated controls to regulate frying conditions, significantly reducing the risk of accidents.

Automated systems often include built-in emergency shutoff mechanisms and temperature monitoring that enhance risk management and minimize operator exposure to hot oil. Countertop fryers, while more affordable, demand rigorous training and vigilance to ensure safe operation and prevent burns or fires. Integrating automation in deep-frying processes optimizes safety by reducing human error and maintaining consistent cooking environments.

Cleaning, Maintenance, and Durability

Countertop deep fryers typically require manual cleaning, involving disassembly of baskets and oil filtration to maintain optimal performance and prolong durability. Automated stir-fry robots feature self-cleaning functions and automated oil filtration systems, significantly reducing maintenance time and effort. While countertop fryers offer straightforward durability, automated robots boast enhanced longevity due to precision controls and consistent operation that minimize wear and tear.

Cost Analysis: Upfront and Long-Term Investment

Countertop deep fryers require a lower initial investment, making them more accessible for small businesses and home use, whereas automated stir-fry robots involve significant upfront costs due to advanced technology. Long-term expenses for countertop fryers include regular maintenance and oil replacement, while stir-fry robots offer savings through labor reduction and consistent cooking efficiency.

- Initial Cost - Countertop deep fryers typically range from $100 to $500, compared to automated stir-fry robots costing upwards of $10,000.

- Maintenance Expenses - Regular oil changes and part replacements increase long-term costs for countertop fryers.

- Labor Savings - Automated stir-fry robots reduce staffing needs, offsetting their higher purchase price over time.

Related Important Terms

Oil-bath filtration integration

Countertop deep fryers typically require manual oil-bath filtration, involving frequent draining and filtering to maintain oil quality and extend its lifespan. Automated stir-fry robots often integrate continuous oil-bath filtration systems, enhancing efficiency by reducing oil degradation and minimizing maintenance downtime during deep-frying operations.

Precision temp sync

Countertop deep fryers offer precise temperature control through built-in thermostats that maintain consistent oil heat for even cooking, preventing overcooking or undercooking. Automated stir-fry robots enhance precision temp sync by integrating real-time temperature sensors and adaptive stirring, ensuring uniform heat distribution and optimal frying conditions.

IoT fryer connectivity

Countertop deep fryers with IoT connectivity offer precise temperature control, real-time monitoring, and remote management via mobile apps, enhancing frying consistency and energy efficiency. Automated stir-fry robots integrate deep-frying functions with IoT systems to optimize cooking cycles, reduce labor, and enable data-driven maintenance, revolutionizing commercial kitchen operations.

Multi-basket rotation system

The multi-basket rotation system in countertop deep fryers enables precise control and uniform frying by allowing simultaneous cooking of multiple items with individual basket rotation. Automated stir-fry robots, however, integrate multi-basket rotation with mechanized stirring to enhance frying consistency, reduce manual intervention, and increase throughput in high-volume commercial kitchens.

Smart oil degradation monitor

Countertop deep fryers with smart oil degradation monitors use sensors to detect oil quality and alert users when replacement is needed, ensuring consistent frying results and food safety. Automated stir-fry robots integrate advanced oil monitoring systems that continuously assess degradation in real-time, optimizing frying conditions and extending oil lifespan for commercial kitchens.

Adaptive agitation blade

Countertop deep fryers often rely on manual or basic mechanical agitation, limiting consistent heat distribution and crispiness in batches, whereas automated stir-fry robots feature adaptive agitation blades that adjust speed and motion based on oil temperature and food type to ensure uniform frying and optimal texture. This technology enhances energy efficiency by reducing oil degradation and minimizes operator intervention, significantly improving throughput and product quality in commercial kitchens.

Touchless auto-drain

Countertop deep fryers typically require manual oil draining, which can be time-consuming and messy, whereas automated stir-fry robots with touchless auto-drain systems enhance safety and efficiency by eliminating direct contact with hot oil during disposal. This hands-free technology reduces the risk of burns and contamination while streamlining kitchen operations in commercial and home settings.

Recipe AI prompt-frying

Countertop deep fryers offer precise temperature control and user-friendly interfaces ideal for traditional deep-frying techniques, while automated stir-fry robots integrate advanced Recipe AI prompt-frying capabilities that optimize cooking times and flavor profiles through real-time adjustments. Recipe AI prompt-frying enhances consistency and efficiency by using machine learning algorithms to tailor frying parameters based on specific ingredient characteristics in both countertop and robotic deep-frying systems.

PID-controlled heat cycling

Countertop deep fryers offer precise PID-controlled heat cycling, ensuring consistent oil temperature for optimal frying results and energy efficiency. Automated stir-fry robots enhance this control by integrating PID systems with mechanical stirring, promoting even heat distribution and reducing cooking time while maintaining food quality.

Countertop deep fryer vs Automated stir-fry robot for deep-frying. Infographic

cookingdiff.com

cookingdiff.com