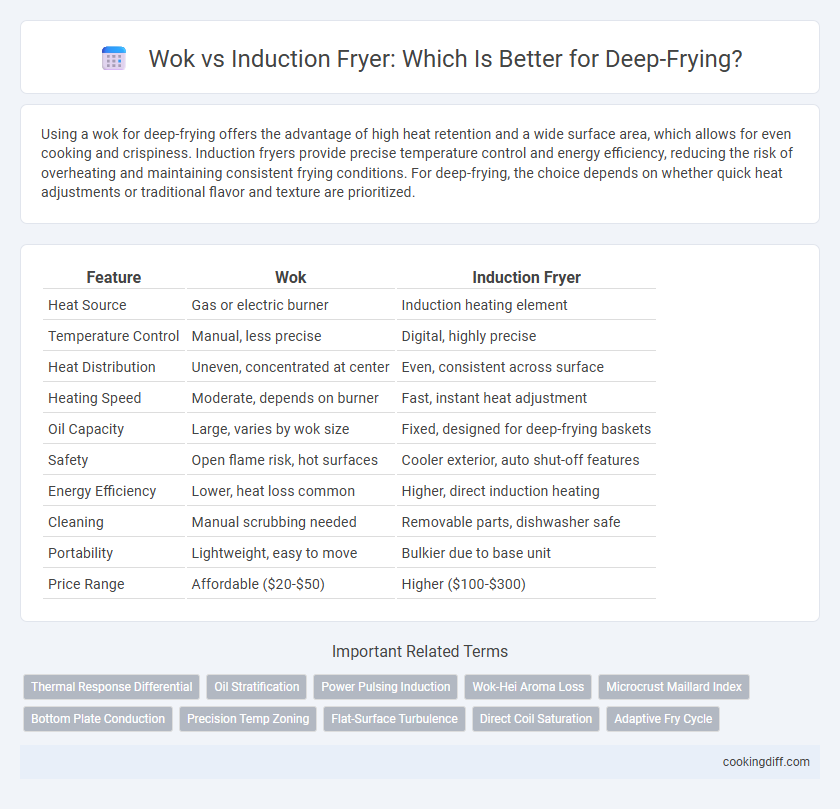

Using a wok for deep-frying offers the advantage of high heat retention and a wide surface area, which allows for even cooking and crispiness. Induction fryers provide precise temperature control and energy efficiency, reducing the risk of overheating and maintaining consistent frying conditions. For deep-frying, the choice depends on whether quick heat adjustments or traditional flavor and texture are prioritized.

Table of Comparison

| Feature | Wok | Induction Fryer |

|---|---|---|

| Heat Source | Gas or electric burner | Induction heating element |

| Temperature Control | Manual, less precise | Digital, highly precise |

| Heat Distribution | Uneven, concentrated at center | Even, consistent across surface |

| Heating Speed | Moderate, depends on burner | Fast, instant heat adjustment |

| Oil Capacity | Large, varies by wok size | Fixed, designed for deep-frying baskets |

| Safety | Open flame risk, hot surfaces | Cooler exterior, auto shut-off features |

| Energy Efficiency | Lower, heat loss common | Higher, direct induction heating |

| Cleaning | Manual scrubbing needed | Removable parts, dishwasher safe |

| Portability | Lightweight, easy to move | Bulkier due to base unit |

| Price Range | Affordable ($20-$50) | Higher ($100-$300) |

Introduction to Deep-Frying: Wok vs Induction Fryer

Deep-frying is a cooking technique that immerses food in hot oil to create a crispy exterior and moist interior. Woks and induction fryers are popular tools for achieving optimal deep-frying results with distinct heat distribution methods.

- Wok heat distribution - The curved shape allows even oil circulation and rapid temperature recovery after food is added.

- Induction fryer precision - Uses electromagnetic heating to maintain consistent oil temperature with digital controls.

- Oil capacity and safety - Woks typically require larger oil volumes, while induction fryers offer controlled oil quantities reducing spill and burn risks.

Choosing between a wok and induction fryer depends on cooking style, heat control preferences, and safety considerations.

Key Differences in Heat Distribution

Woks provide uneven heat distribution with concentrated heat at the bottom, suitable for quick stir-frying but challenging for uniform deep-frying. Induction fryers deliver precise, consistent heat across the entire cooking surface, optimizing temperature control for deep-frying.

- Wok Bottom Heat Concentration - Heat concentrates at the wok's base, causing hotspots and uneven frying.

- Induction Fryer Even Heat Distribution - Uses electromagnetic energy for consistent heat spread across the frying vessel.

- Temperature Control Precision - Induction fryers maintain stable temperatures, reducing oil degradation and improving food texture.

Oil Temperature Control and Stability

Woks offer rapid heat distribution that enables quick temperature changes, but they often lack precise oil temperature control during deep-frying. Induction fryers provide consistent temperature stability through electromagnetic heating, ensuring optimal oil temperature maintenance for better frying results.

Oil temperature in a wok can fluctuate due to its open design and manual heat adjustments, potentially affecting food texture and oil longevity. Induction fryers use digital controls and thermostats to maintain steady heat, reducing oil degradation and improving frying efficiency.

Efficiency and Energy Consumption

Woks heat up rapidly due to direct contact with the flame, allowing efficient temperature control for deep-frying with minimal energy loss. Induction fryers use electromagnetic energy to heat the cookware directly, resulting in faster heat-up times and significantly lower energy consumption compared to traditional gas setups. Energy Efficiency Ratio (EER) measurements show induction fryers can reduce energy use by up to 30% during prolonged deep-frying sessions.

Cooking Capacity and Volume

Woks typically offer a larger cooking capacity suitable for frying larger volumes of food at once, thanks to their wide, open design. Induction fryers provide precise temperature control but generally have a smaller volume capacity, making them ideal for smaller batch deep-frying.

- Wok Capacity - The wide and deep shape of a wok allows for frying large quantities of food, making it efficient for high-volume cooking.

- Induction Fryer Volume - Induction fryers usually have a fixed, smaller frying basket that limits the volume of food that can be fried at one time.

- Cooking Efficiency - While woks can handle a broader volume, induction fryers offer consistent heat, improving cooking precision for smaller batches.

Versatility in Deep-Frying Techniques

| Wok | Offers exceptional versatility for deep-frying a variety of ingredients due to its wide, sloped sides that facilitate easy stirring and quick oil temperature adjustment. |

| Induction Fryer | Provides precise temperature control ideal for consistent deep-frying but is less adaptable for techniques requiring frequent movement or multiple ingredient layering. |

| Versatility Comparison | The wok excels in handling diverse frying methods such as tossing and shallow frying, while induction fryers prioritize temperature stability suited for uniform, batch cooking. |

Safety Features and Risk Management

Woks used for deep-frying often lack built-in safety features, increasing the risk of oil splatters and burns due to open flames and unstable surfaces. Induction fryers incorporate automatic temperature controls and overheat protection sensors to minimize fire hazards and maintain consistent frying temperatures.

Induction fryers offer superior risk management by ensuring precise heat regulation and reducing the chances of oil ignition, which is a common hazard with traditional wok frying. Their enclosed design also prevents accidental contact with hot oil, enhancing user safety during deep-frying operations.

Cleaning and Maintenance Comparison

Woks require frequent seasoning and careful cleaning to prevent rust and maintain their non-stick surface, often needing manual scrubbing. Induction fryers feature detachable, dishwasher-safe components that simplify cleaning and reduce maintenance efforts.

Maintaining a wok involves oiling and drying thoroughly after each use to avoid corrosion, which can be time-consuming. In contrast, induction fryers have sealed electronic parts, minimizing the risk of damage during cleaning. Regular descaling and wiping the heating element ensure the induction fryer operates efficiently and prolongs its lifespan.

Flavor Outcomes: Taste and Texture

Wok deep-frying delivers a distinct smoky flavor and crisp texture due to its high heat and open design, allowing fast moisture evaporation. Induction fryers provide consistent temperature control, resulting in evenly cooked food with a uniform golden crust but less charred depth. Flavor outcomes favor woks for authentic taste and texture, while induction fryers excel in precision and repeatability.

Related Important Terms

Thermal Response Differential

Woks provide rapid thermal response due to their direct flame contact and curved design, allowing quick temperature adjustments essential for deep-frying precision. Induction fryers offer more consistent and evenly distributed heat through electromagnetic fields, minimizing thermal lag but potentially reacting slower to sudden temperature changes compared to traditional woks.

Oil Stratification

Woks promote natural oil stratification due to their concave shape and high heat concentration, enabling even cooking and crispiness by allowing food to float and fry in different oil layers. Induction fryers maintain consistent oil temperature but lack the dynamic oil movement, which can result in less effective oil stratification and potentially uneven frying textures.

Power Pulsing Induction

Power Pulsing Induction technology in induction fryers ensures rapid temperature recovery and consistent heat distribution, outperforming traditional woks in maintaining optimal frying conditions. This efficiency reduces oil absorption and produces crispier, evenly cooked foods, making induction fryers ideal for precise deep-frying control.

Wok-Hei Aroma Loss

Wok deep-frying imparts a unique Wok-Hei aroma characterized by high heat and rapid cooking, which is often diminished when using an induction fryer due to its precise temperature control but lack of intense flame exposure. The absence of direct flame interaction in induction fryers leads to a noticeable loss of the smoky, charred flavor profile prized in traditional wok-cooked dishes.

Microcrust Maillard Index

Woks typically achieve higher temperatures faster, enhancing the Maillard reaction and producing a superior Microcrust Maillard Index with richer browning and flavor complexity during deep-frying. Induction fryers provide precise temperature control but may result in a slightly lower Microcrust Maillard Index due to more even heat distribution and less intense surface heat.

Bottom Plate Conduction

Wok deep-frying relies on a rounded bottom that distributes heat unevenly through direct flame, resulting in hotspots that require constant stirring for uniform cooking. Induction fryers use a flat bottom plate with electromagnetic conduction, providing consistent and efficient heat transfer across the entire cooking surface for precise temperature control during deep-frying.

Precision Temp Zoning

Woks provide variable heat zones due to their curved shape, allowing cooks to move food between different temperature areas for precise control, but induction fryers offer more accurate and consistent temperature settings through electronic controls and uniform heat distribution. Induction fryers maintain exact precision temp zoning with rapid adjustments and steady heat, enhancing cooking consistency compared to the more manual heat management of traditional woks.

Flat-Surface Turbulence

A wok's curved shape generates natural flat-surface turbulence, promoting even heat distribution and efficient oil circulation during deep-frying, resulting in crispier textures. In contrast, induction fryers typically have flat surfaces that may require additional design features to replicate this turbulence, affecting the uniformity of frying and oil temperature stability.

Direct Coil Saturation

Woks provide uneven direct coil saturation which can cause hot spots and inconsistent oil temperature during deep-frying, impacting food quality and safety. Induction fryers utilize electromagnetic fields for uniform heat distribution, ensuring precise temperature control and energy efficiency for optimal deep-frying results.

Wok vs Induction fryer for deep-frying. Infographic

cookingdiff.com

cookingdiff.com