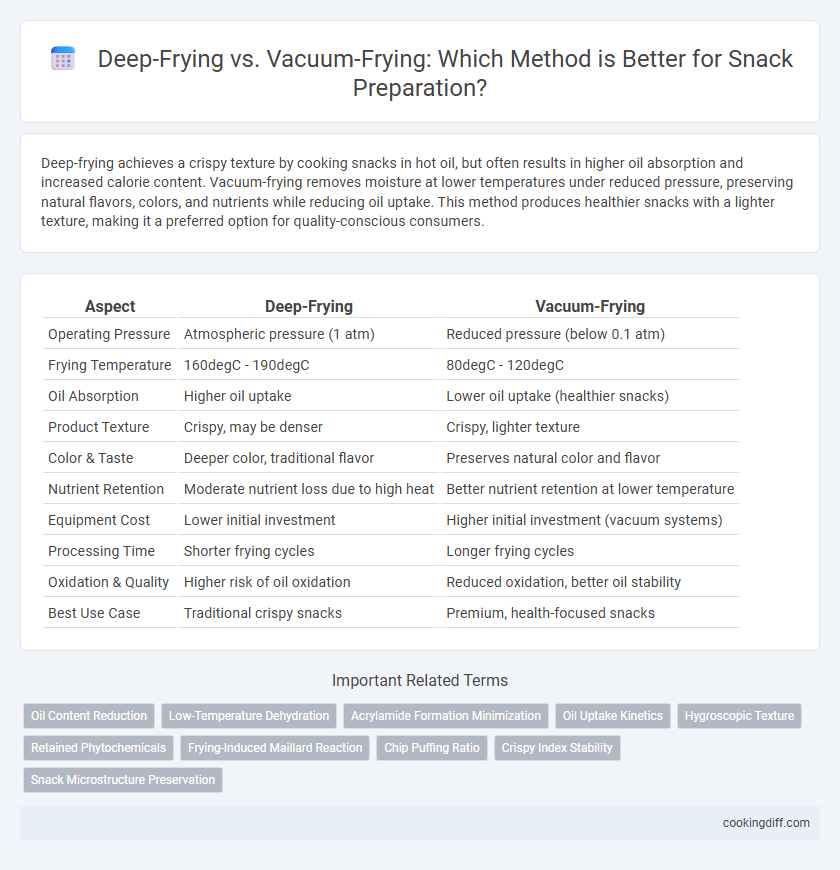

Deep-frying achieves a crispy texture by cooking snacks in hot oil, but often results in higher oil absorption and increased calorie content. Vacuum-frying removes moisture at lower temperatures under reduced pressure, preserving natural flavors, colors, and nutrients while reducing oil uptake. This method produces healthier snacks with a lighter texture, making it a preferred option for quality-conscious consumers.

Table of Comparison

| Aspect | Deep-Frying | Vacuum-Frying |

|---|---|---|

| Operating Pressure | Atmospheric pressure (1 atm) | Reduced pressure (below 0.1 atm) |

| Frying Temperature | 160degC - 190degC | 80degC - 120degC |

| Oil Absorption | Higher oil uptake | Lower oil uptake (healthier snacks) |

| Product Texture | Crispy, may be denser | Crispy, lighter texture |

| Color & Taste | Deeper color, traditional flavor | Preserves natural color and flavor |

| Nutrient Retention | Moderate nutrient loss due to high heat | Better nutrient retention at lower temperature |

| Equipment Cost | Lower initial investment | Higher initial investment (vacuum systems) |

| Processing Time | Shorter frying cycles | Longer frying cycles |

| Oxidation & Quality | Higher risk of oil oxidation | Reduced oxidation, better oil stability |

| Best Use Case | Traditional crispy snacks | Premium, health-focused snacks |

Introduction to Deep-Frying and Vacuum-Frying

Deep-frying is a traditional cooking method where food is submerged in hot oil at temperatures typically between 160degC and 190degC, resulting in a crispy texture and enhanced flavor. This process is widely used for snack preparation due to its ability to quickly cook food while creating a golden, crunchy exterior.

Vacuum-frying involves cooking food under reduced pressure, which lowers the boiling point of oil, allowing frying at temperatures around 90degC to 120degC. This method preserves the natural color and nutrients of snacks, reduces oil absorption, and produces a healthier product compared to conventional deep-frying.

Key Principles of Deep-Frying

Deep-frying involves cooking food by submerging it in hot oil at temperatures typically between 160-190degC, which rapidly creates a crispy outer layer. Vacuum-frying, in contrast, uses lower temperatures under reduced pressure to preserve color and nutrients while producing a less oily snack.

- High Temperature Cooking - Deep-frying relies on temperatures around 170-190degC to quickly evaporate moisture and form a golden crust on the snack.

- Oil Absorption - The intense heat during deep-frying results in higher oil uptake compared to vacuum-frying, affecting texture and calorie content.

- Oxygen Exposure - Standard deep-frying exposes food to oxygen, leading to faster oxidation and potential nutrient degradation, unlike the low-oxygen environment in vacuum-frying.

How Vacuum-Frying Works

Vacuum-frying involves cooking snacks at low temperatures under reduced pressure, which lowers the boiling point of oil and water. This process preserves the natural color, flavor, and nutrients of the food better than traditional deep-frying.

By frying in a vacuum environment, moisture evaporates more gently, resulting in less oil absorption and a crispier texture. The reduced oxidation during vacuum-frying minimizes harmful compounds and extends the shelf life of snacks. This technique is particularly effective for sensitive ingredients like fruits and vegetables, producing healthier, high-quality snacks.

Oil Absorption: Deep-Frying vs Vacuum-Frying

Deep-frying typically results in higher oil absorption due to atmospheric pressure allowing oil to penetrate snack surfaces more deeply. Vacuum-frying reduces oil uptake by frying under low pressure, which lowers the boiling point of oil and decreases the time snacks are exposed to hot oil. This method produces snacks with less oil content while maintaining crispiness and flavor integrity.

Nutrient Retention in Snack Preparation

Vacuum-frying preserves a higher level of nutrients such as vitamins A and C in snacks compared to traditional deep-frying due to lower operating temperatures and reduced oxygen exposure. This method minimizes nutrient degradation and oxidation, resulting in healthier snack options with better flavor retention. Deep-frying at high temperatures often causes significant nutrient loss and formation of harmful compounds.

Texture and Flavor Differences

Deep-frying produces snacks with a crispier texture due to high-temperature oil contact, which enhances Maillard reactions for rich, savory flavors. Vacuum-frying uses lower temperatures under reduced pressure, preserving delicate flavors and resulting in a lighter, less oily texture.

- Deep-frying Texture - Creates a crunchy, robust exterior by rapidly dehydrating the snack surface.

- Vacuum-frying Flavor Preservation - Retains natural snack flavors by minimizing oxidation during frying.

- Oil Absorption Differences - Vacuum-frying reduces oil uptake leading to a less greasy mouthfeel.

Choosing between methods depends on desired snack characteristics, balancing crispiness with flavor integrity.

Health Implications of Each Method

How do deep-frying and vacuum-frying compare in terms of health implications for snack preparation? Deep-frying typically results in higher oil absorption, increasing calorie content and the presence of harmful compounds like acrylamide. Vacuum-frying uses lower temperatures and reduced oxygen levels, which helps preserve nutrients and reduces the formation of unhealthy substances, making it a healthier alternative for snack production.

Energy Efficiency and Equipment Needs

Deep-frying requires higher temperatures and longer cooking times, resulting in increased energy consumption compared to vacuum-frying. Vacuum-frying operates at lower temperatures under reduced pressure, significantly enhancing energy efficiency during snack preparation.

Equipment for deep-frying typically involves standard fryers with basic temperature control, while vacuum-frying demands specialized vacuum chambers and robust sealing systems. The initial investment and maintenance costs for vacuum-frying equipment are higher, but the energy savings and improved product quality can offset these expenses over time.

Cost Considerations for Snack Producers

| Deep-frying generally incurs lower initial equipment costs compared to vacuum-frying, making it more accessible for small to medium-sized snack producers. |

| Vacuum-frying requires specialized machinery and controlled environments, leading to higher capital investments and increased operational expenses due to energy consumption. |

| While vacuum-frying offers potential savings through reduced oil absorption and longer oil life, the overall cost-effectiveness depends on the scale of production and product quality priorities. |

Related Important Terms

Oil Content Reduction

Vacuum-frying significantly reduces oil absorption in snacks by frying at lower temperatures under reduced pressure, preserving texture and nutritional value compared to traditional deep-frying. This method lowers oil content by up to 50%, resulting in healthier, less greasy snack products.

Low-Temperature Dehydration

Vacuum-frying uses low-temperature dehydration, typically between 80-120degC, reducing oil absorption and preserving nutritional quality compared to deep-frying, which operates at higher temperatures around 170-190degC. This technique maintains texture and flavor of snacks while minimizing harmful compound formation such as acrylamide.

Acrylamide Formation Minimization

Vacuum-frying significantly reduces acrylamide formation in snack preparation by frying at lower temperatures and reduced oxygen levels, compared to traditional deep-frying which occurs at higher temperatures and can accelerate acrylamide generation. Studies show vacuum-fried snacks contain up to 70% less acrylamide, enhancing food safety and consumer health benefits.

Oil Uptake Kinetics

Deep-frying typically results in higher oil uptake kinetics due to the direct contact of food with oil at elevated temperatures, causing rapid moisture loss and surface oil absorption. Vacuum-frying, conducted at lower pressures and temperatures, slows oil uptake kinetics by reducing moisture evaporation rates, yielding snacks with less oil content and improved nutritional profiles.

Hygroscopic Texture

Deep-frying produces snacks with a crisp texture but often results in higher moisture uptake, leading to increased hygroscopicity and reduced shelf life. Vacuum-frying preserves the low moisture content and structural integrity of snacks, minimizing hygroscopic texture and enhancing prolonged crispness during storage.

Retained Phytochemicals

Vacuum-frying preserves higher levels of phytochemicals such as carotenoids and polyphenols in snacks compared to traditional deep-frying, due to lower processing temperatures and reduced oxygen exposure. This method enhances the nutritional quality and antioxidant capacity of the final product, making vacuum-frying a superior technique for retaining bioactive compounds in snack preparation.

Frying-Induced Maillard Reaction

Deep-frying induces a robust Maillard reaction due to high temperatures and oxygen-rich environments, enhancing browning and flavor development in snacks but also generating potentially harmful acrylamides. Vacuum-frying operates at lower temperatures and reduced oxygen pressure, resulting in milder Maillard browning with retained nutritional quality and decreased acrylamide formation, making it a healthier alternative for snack preparation.

Chip Puffing Ratio

Deep-frying typically results in higher chip puffing ratios due to rapid moisture vaporization and oil absorption, creating a crispier texture with increased volume. Vacuum-frying, conducted at lower pressures and temperatures, reduces puffing ratio while preserving color and nutrients, yielding denser snacks with less oil content.

Crispy Index Stability

Vacuum-frying maintains a more stable Crispy Index by reducing oil absorption and minimizing oxidative degradation, resulting in consistently crispier snacks compared to traditional deep-frying. The lower frying temperature and reduced oxygen exposure in vacuum-frying preserve texture integrity and extend shelf-life stability.

Deep-frying vs Vacuum-frying for snack preparation. Infographic

cookingdiff.com

cookingdiff.com