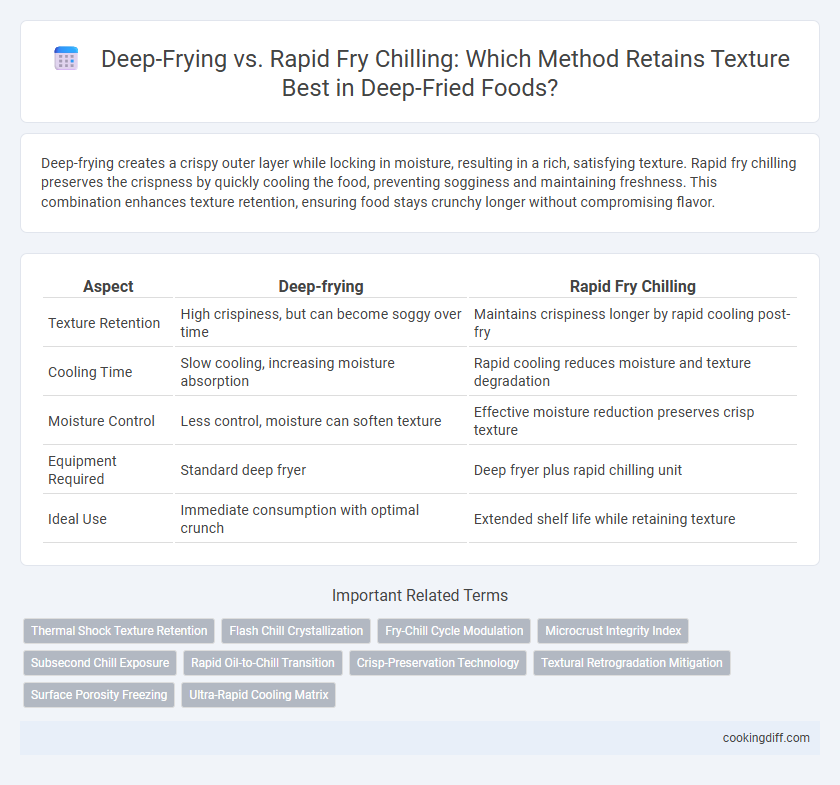

Deep-frying creates a crispy outer layer while locking in moisture, resulting in a rich, satisfying texture. Rapid fry chilling preserves the crispness by quickly cooling the food, preventing sogginess and maintaining freshness. This combination enhances texture retention, ensuring food stays crunchy longer without compromising flavor.

Table of Comparison

| Aspect | Deep-frying | Rapid Fry Chilling |

|---|---|---|

| Texture Retention | High crispiness, but can become soggy over time | Maintains crispiness longer by rapid cooling post-fry |

| Cooling Time | Slow cooling, increasing moisture absorption | Rapid cooling reduces moisture and texture degradation |

| Moisture Control | Less control, moisture can soften texture | Effective moisture reduction preserves crisp texture |

| Equipment Required | Standard deep fryer | Deep fryer plus rapid chilling unit |

| Ideal Use | Immediate consumption with optimal crunch | Extended shelf life while retaining texture |

Introduction to Deep-frying and Rapid Fry Chilling

Deep-frying is a cooking method that immerses food in hot oil, achieving a crispy texture through rapid high-temperature cooking. Rapid fry chilling combines deep-frying with immediate cooling, preserving the food's texture and extending shelf life by locking in moisture. This technique enhances texture retention by minimizing moisture loss compared to traditional deep-frying alone.

How Deep-frying Affects Food Texture

Deep-frying creates a crispy, golden crust by rapidly dehydrating the food's surface, which locks in moisture and enhances texture contrast. The high heat causes Maillard reactions that improve flavor and produce a satisfying crunch.

Rapid fry chilling aims to preserve this crispy texture by quickly reducing the temperature while preventing sogginess and oil absorption. This method maintains the food's firmness and reduces texture degradation compared to traditional cooling techniques.

Rapid Fry Chilling: Process Overview

Rapid fry chilling involves quickly lowering the temperature of deep-fried foods immediately after frying, which preserves moisture and prevents overcooking. This process significantly enhances texture retention compared to traditional deep-frying alone, resulting in a crispier exterior and a tender interior.

The key steps include frying at high temperatures followed by swift chilling using cold air or refrigeration technology within minutes. Rapid fry chilling reduces oil absorption, extending shelf life and maintaining the product's original quality during storage and reheating.

Comparing Texture Retention: Deep-frying vs Rapid Fry Chilling

Deep-frying preserves a crispy exterior and moist interior by rapidly cooking food at high temperatures, locking in texture and flavor. Rapid fry chilling involves quick cooling after frying, which helps maintain the crunchy crust while preventing sogginess in subsequent reheating. Studies show rapid fry chilling offers superior texture retention for pre-cooked products compared to traditional deep-frying processes alone.

Moisture Content and Crispiness Differences

Deep-frying maintains higher moisture content within the food's interior, resulting in a juicier texture, while the rapid fry chilling process prioritizes cooling and preservation, which can lead to a slight moisture loss. Crispiness is more pronounced and longer-lasting in deep-fried foods due to the high oil temperature creating a robust crust compared to the softer exterior after rapid fry chilling.

- Higher Moisture Retention - Deep-frying seals moisture inside food by quickly cooking the surface, preventing excessive water loss.

- Enhanced Crispiness - The intense heat in deep-frying produces a crunchy and well-defined crust that contrasts with the softer texture of rapid fry chilled items.

- Moisture Loss in Rapid Fry Chilling - Rapid fry chilling causes some evaporative moisture loss during cooling, reducing internal juiciness but helping preserve food quality over time.

The balance between moisture content and crispiness determines the preferred method for texture retention in fried foods.

Oil Absorption Impact on Food Texture

Deep-frying often results in higher oil absorption, which significantly affects the crispiness and moisture retention in food. Rapid fry chilling reduces oil uptake, maintaining a firmer texture and less greasy mouthfeel.

- Oil Absorption in Deep-Frying - Deep-frying causes food to absorb more oil, making the texture richer but potentially heavier and greasier.

- Texture Preservation in Rapid Fry Chilling - Rapid fry chilling minimizes oil retention, preserving the food's crisp outer layer and moist interior more effectively.

- Impact on Food Quality - Lower oil absorption through rapid fry chilling enhances the health profile and sensory experience by keeping the texture crisp without excess greasiness.

Time and Temperature Influence on Texture

Deep-frying uses high temperatures (typically 160-190degC) for a short duration to rapidly cook food, creating a crispy texture through Maillard reactions. Rapid fry chilling involves quickly lowering the temperature after frying to preserve moisture and prevent sogginess.

- Time Impact - Longer frying times increase moisture loss, resulting in a harder texture, while rapid chilling minimizes this effect.

- Temperature Control - Maintaining optimal deep-frying temperature ensures uniform crispness without overcooking the interior.

- Texture Retention - Rapid fry chilling helps retain tenderness by preventing continued cooking and moisture evaporation post-frying.

Suitability for Different Food Types

| Deep-frying | Ideal for foods with high moisture content like potatoes and chicken, producing a crispy exterior while locking in juiciness. |

| Rapid Fry Chilling | Best suited for delicate items such as seafood and pastries, maintaining texture by minimizing moisture loss and preventing overcooking. |

| Comparison | Deep-frying excels in creating a crunchy crust but may not preserve texture in fragile foods, whereas rapid fry chilling enhances texture retention across a broader range of ingredients. |

Practical Applications in Commercial Kitchens

Deep-frying maintains superior crispiness and moisture retention in foods, making it ideal for commercial kitchens focused on delivering consistent texture and flavor. Rapid fry chilling, by contrast, slows the cooling process after frying, preserving texture but requiring additional equipment and workflow adjustments.

In commercial kitchens, using deep-frying ensures quick service with optimum texture, essential for high-volume operations. Rapid fry chilling enhances food quality for batch preparation and minimizes texture degradation during holding periods. Combining both methods optimizes texture retention and operational efficiency in fast-paced environments.

Related Important Terms

Thermal Shock Texture Retention

Deep-frying exposes food to high temperatures, creating a crispy exterior but may cause significant moisture loss and texture degradation due to rapid heat transfer. In contrast, rapid fry chilling minimizes thermal shock by quickly reducing temperature, better preserving internal moisture and texture integrity for an improved mouthfeel and longer shelf life.

Flash Chill Crystallization

Flash Chill Crystallization during rapid fry chilling preserves the crispy texture of deep-fried foods by quickly solidifying the fat, preventing oil reabsorption and sogginess. This process contrasts with traditional deep-frying, where slower cooling allows fat migration, resulting in texture degradation.

Fry-Chill Cycle Modulation

Fry-chill cycle modulation enhances texture retention by precisely controlling the temperature and timing between deep-frying and rapid chilling phases, preventing moisture loss and crispness degradation. This method ensures a consistent crispy exterior and tender interior, outperforming traditional deep-frying in maintaining product quality during storage and reheating.

Microcrust Integrity Index

Deep-frying preserves the Microcrust Integrity Index by creating a robust, crispy exterior through high-temperature oil immersion, which rapidly seals moisture inside the food. Rapid fry chilling, while reducing oil absorption and cooking time, can compromise the microcrust structure, resulting in diminished texture retention and lower Microcrust Integrity Index values.

Subsecond Chill Exposure

Subsecond chill exposure in rapid fry chilling significantly enhances texture retention by halting the cooking process immediately after deep-frying, preventing moisture loss and maintaining crispiness. This precise temperature control contrasts with traditional deep-frying, where longer cooling times cause sogginess and a decline in product quality.

Rapid Oil-to-Chill Transition

Rapid fry chilling enables a rapid oil-to-chill transition that effectively locks in moisture and preserves the crisp texture of deep-fried foods. This method reduces oil absorption during cooling, resulting in a firmer, less greasy final product compared to traditional deep-frying.

Crisp-Preservation Technology

Deep-frying achieves superior texture retention by immersing food in hot oil, producing a crispy exterior through Maillard reaction and moisture evaporation, whereas Rapid Fry Chilling employs immediate temperature reduction post-fry to lock in crispiness and extend shelf life. Crisp-Preservation Technology enhances these methods by combining controlled cooling and surface dehydration to maintain optimal food crunchiness during storage and reheating.

Textural Retrogradation Mitigation

Rapid fry chilling significantly reduces textural retrogradation by rapidly lowering the temperature of deep-fried foods, preserving crispness and moisture better than conventional deep-frying alone. This technique minimizes starch recrystallization and moisture migration, ensuring superior texture retention and extended shelf-life.

Surface Porosity Freezing

Deep-frying maintains superior surface porosity, creating a crispy, aerated outer layer that enhances texture retention better than rapid fry chilling. Surface porosity freezing in rapid fry chilling tends to form denser, less porous crusts, resulting in diminished crispness and moisture retention compared to traditional deep-frying methods.

Deep-frying vs Rapid fry chilling for texture retention. Infographic

cookingdiff.com

cookingdiff.com