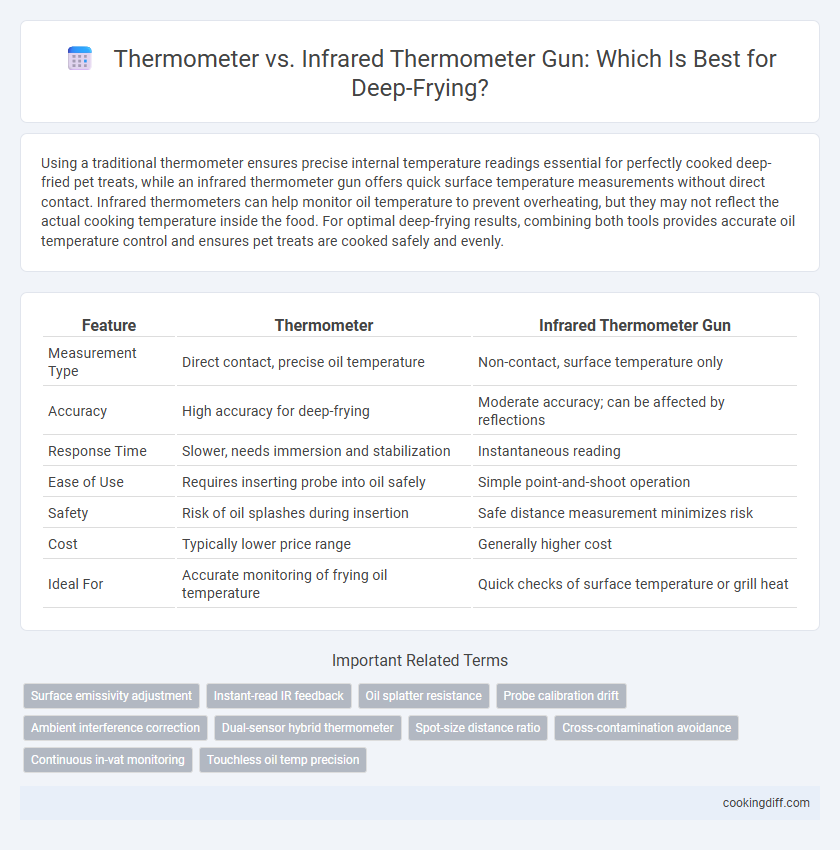

Using a traditional thermometer ensures precise internal temperature readings essential for perfectly cooked deep-fried pet treats, while an infrared thermometer gun offers quick surface temperature measurements without direct contact. Infrared thermometers can help monitor oil temperature to prevent overheating, but they may not reflect the actual cooking temperature inside the food. For optimal deep-frying results, combining both tools provides accurate oil temperature control and ensures pet treats are cooked safely and evenly.

Table of Comparison

| Feature | Thermometer | Infrared Thermometer Gun |

|---|---|---|

| Measurement Type | Direct contact, precise oil temperature | Non-contact, surface temperature only |

| Accuracy | High accuracy for deep-frying | Moderate accuracy; can be affected by reflections |

| Response Time | Slower, needs immersion and stabilization | Instantaneous reading |

| Ease of Use | Requires inserting probe into oil safely | Simple point-and-shoot operation |

| Safety | Risk of oil splashes during insertion | Safe distance measurement minimizes risk |

| Cost | Typically lower price range | Generally higher cost |

| Ideal For | Accurate monitoring of frying oil temperature | Quick checks of surface temperature or grill heat |

Introduction to Temperature Control in Deep-Frying

Accurate temperature control is crucial in deep-frying to ensure food is cooked evenly and achieves the desired crispiness without absorbing excess oil. Traditional thermometers measure the oil's internal temperature by direct contact, providing consistent and reliable readings. Infrared thermometer guns offer a non-contact alternative that measures surface temperature quickly but may be less accurate for deep-frying oil due to reflective surfaces and uneven heat distribution.

Why Accurate Temperature Matters in Deep-Frying

Why is accurate temperature measurement essential in deep-frying? Precise temperature control prevents oil degradation and ensures foods cook evenly, achieving the perfect crispy texture. Infrared thermometer guns measure surface heat quickly but can miss the oil's true internal temperature, making traditional immersion thermometers more reliable for deep-frying accuracy.

Overview: Traditional Thermometers vs. Infrared Thermometer Guns

Traditional thermometers measure the oil temperature by direct contact, providing accurate readings essential for consistent deep-frying results. Infrared thermometer guns offer a non-contact alternative, allowing quick surface temperature checks without immersion in hot oil. While infrared devices are convenient and reduce contamination risk, they may not capture the oil's true internal temperature compared to traditional probes.

How Standard Deep-Frying Thermometers Work

Standard deep-frying thermometers measure the temperature by being immersed directly in the hot oil, using a metal probe connected to a dial or digital readout that detects heat transfer through conduction. This direct-contact method ensures accurate temperature readings vital for maintaining optimal frying conditions and preventing oil degradation or undercooking.

Infrared thermometer guns, in contrast, measure surface temperature without contact by detecting thermal radiation, but they are less reliable for deep-frying because they only assess the oil's surface temperature, which can fluctuate and differ from the oil's actual frying temperature. A standard deep-frying thermometer provides consistent and precise monitoring essential for food safety and cooking quality during the frying process.

How Infrared Thermometer Guns Function

| Infrared thermometer guns measure surface temperature by detecting emitted infrared radiation, making them ideal for quick, non-contact readings during deep-frying. |

| These devices convert infrared energy into an electrical signal, which is then displayed as a temperature value, providing instant feedback without contaminating the oil. |

| Unlike traditional thermometers that require immersion, infrared guns ensure safety and hygiene while efficiently monitoring oil temperature to maintain optimal frying conditions. |

Accuracy Comparison: Immersion vs. Infrared Readings

Immersion thermometers provide direct contact with the oil, delivering highly accurate temperature readings essential for deep-frying. Infrared thermometer guns measure surface temperature, which can fluctuate due to oil agitation and may not reflect the true internal oil temperature.

Using an immersion thermometer ensures consistent heat levels critical for proper cooking and food safety, preventing undercooked or burnt results. Infrared thermometers offer quick, non-invasive checks but can be less reliable in deep-frying due to surface temperature variance. For precise temperature control in frying oils, immersion thermometers remain the preferred choice among professional chefs and culinary experts.

Response Time and Convenience in Deep-Frying

Traditional thermometers offer precise temperature readings but require submersion in oil, slowing down the frying process. Infrared thermometer guns provide instant surface temperature measurements, enhancing convenience without direct contact with hot oil.

- Response Time Advantage - Infrared thermometers deliver temperature readings within seconds, enabling quicker adjustments during frying.

- Convenience Factor - Infrared guns allow for non-contact temperature checks, reducing the risk of burns and oil splatter.

- Measurement Accuracy - Traditional thermometers measure the internal oil temperature, providing consistent data crucial for deep-frying quality.

Choosing between the two depends on balancing response time and accuracy for optimal deep-frying performance.

Safety Considerations When Using Each Device

Using a traditional probe thermometer for deep-frying ensures accurate internal temperature readings of the oil, reducing the risk of overheating and potential fires. Its direct contact provides precise monitoring, but users must handle it carefully to avoid burns from hot oil splashes.

Infrared thermometer guns offer a non-contact method, enhancing safety by allowing temperature measurement from a distance without risking exposure to hot oil. However, their readings can be less accurate on reflective surfaces like oil, so caution is needed when relying solely on this device for temperature control.

Cleaning and Maintenance: Which is Easier?

Traditional deep-frying thermometers require thorough cleaning after exposure to hot oil, often needing careful washing to avoid damage. Infrared thermometer guns offer easier maintenance since they do not touch the oil and only require wiping the sensor lens.

- Traditional Thermometer Cleaning - Immersion in hot oil necessitates careful hand-washing to remove residue and prevent corrosion or damage.

- Infrared Thermometer Maintenance - Non-contact operation allows for quick cleaning by simply wiping the sensor lens with a soft cloth.

- Durability Impact - Frequent oil exposure can shorten the lifespan of traditional thermometers, while infrared guns maintain accuracy longer with minimal maintenance.

Related Important Terms

Surface emissivity adjustment

Thermometers designed for deep-frying typically provide direct temperature readings with precise calibration, while infrared thermometer guns require careful surface emissivity adjustment to ensure accurate surface temperature measurements of hot oil. Proper emissivity settings on infrared guns prevent errors caused by oil reflections and differing surface properties, making them less reliable without calibration compared to immersion thermometers.

Instant-read IR feedback

Instant-read infrared thermometer guns provide rapid, non-contact temperature measurements essential for deep-frying to maintain consistent oil temperature between 350degF and 375degF, reducing the risk of undercooked or burnt food. Unlike traditional probe thermometers, infrared guns detect surface temperature instantly, enabling quick adjustments without interrupting the cooking process or contaminating the oil.

Oil splatter resistance

Traditional deep-frying thermometers offer superior oil splatter resistance due to their durable probes designed to be immersed directly in hot oil, while infrared thermometer guns may be less effective as their sensors can be obscured or damaged by oil splatters. Choosing a probe thermometer ensures consistent temperature readings and better protection against oil splatter during deep-frying processes.

Probe calibration drift

Traditional probe thermometers provide accurate and consistent temperature readings critical for deep-frying but can suffer from calibration drift over time due to repeated exposure to extreme heat. Infrared thermometer guns offer quick surface temperature measurements without contact, yet they may not effectively reflect the oil's true internal temperature, making regular calibration checks essential to ensure precision during frying.

Ambient interference correction

Thermometer probes provide direct, accurate temperature readings in deep-frying by immersing them in the oil, minimizing ambient interference effects common with infrared thermometer guns that measure surface temperatures and can be skewed by surrounding heat sources. Infrared thermometer guns require ambient interference correction to adjust for reflective heat and air temperature variations, but may still deliver less precise readings compared to probe thermometers designed for high-temperature oil environments.

Dual-sensor hybrid thermometer

A dual-sensor hybrid thermometer combines the precise, direct-contact temperature measurement of a traditional probe with the non-contact, rapid-read capabilities of an infrared thermometer gun, optimizing accuracy and convenience for deep-frying. This hybrid device ensures consistent oil temperature monitoring by quickly detecting surface heat with the infrared sensor while verifying internal oil temperature through the probe for perfect frying results.

Spot-size distance ratio

A traditional probe thermometer provides precise temperature readings directly within the oil, ensuring accurate monitoring during deep-frying, while an infrared thermometer gun measures surface temperatures with a spot-size distance ratio that can lead to inaccurate readings if held too far from the oil. Maintaining the recommended distance for the infrared thermometer is crucial to avoid averaging temperatures over a larger area, which can distort critical temperature control necessary for optimal frying results.

Cross-contamination avoidance

Using a traditional thermometer with a probe for deep-frying allows direct measurement of oil temperature while minimizing the risk of cross-contamination by proper sterilization between uses. Infrared thermometer guns provide non-contact surface temperature readings, reducing physical contact and further limiting cross-contamination risks in food safety protocols.

Continuous in-vat monitoring

Using a traditional probe thermometer enables continuous in-vat temperature monitoring during deep-frying, ensuring precise oil temperature control for consistent cooking results. Infrared thermometer guns provide non-contact surface readings but lack the ability for continuous monitoring, making them less effective for maintaining stable deep-frying heat levels.

Thermometer vs infrared thermometer gun for deep-frying. Infographic

cookingdiff.com

cookingdiff.com