Deep-frying involves submerging food in hot oil to achieve a crispy texture, while pressure-frying combines the benefits of deep-frying with pressure cooking to cook food faster and retain more moisture. Pressure-frying results in juicier, more tender dishes by sealing in flavors and reducing oil absorption compared to traditional deep-frying. Choosing between the two methods depends on desired texture, cooking time, and equipment availability for optimal culinary results.

Table of Comparison

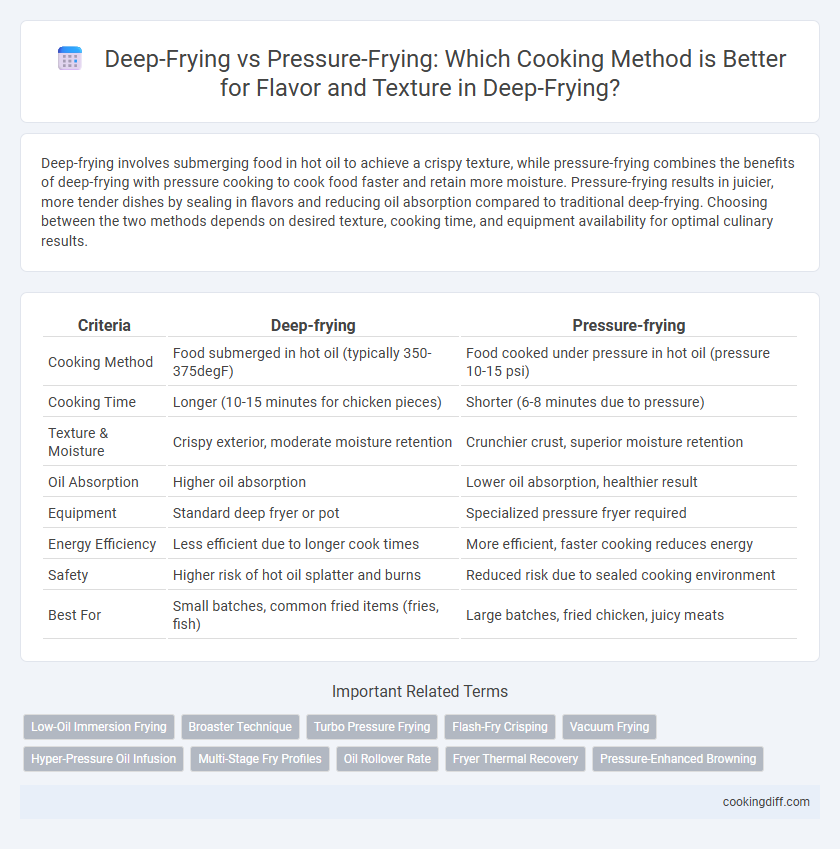

| Criteria | Deep-frying | Pressure-frying |

|---|---|---|

| Cooking Method | Food submerged in hot oil (typically 350-375degF) | Food cooked under pressure in hot oil (pressure 10-15 psi) |

| Cooking Time | Longer (10-15 minutes for chicken pieces) | Shorter (6-8 minutes due to pressure) |

| Texture & Moisture | Crispy exterior, moderate moisture retention | Crunchier crust, superior moisture retention |

| Oil Absorption | Higher oil absorption | Lower oil absorption, healthier result |

| Equipment | Standard deep fryer or pot | Specialized pressure fryer required |

| Energy Efficiency | Less efficient due to longer cook times | More efficient, faster cooking reduces energy |

| Safety | Higher risk of hot oil splatter and burns | Reduced risk due to sealed cooking environment |

| Best For | Small batches, common fried items (fries, fish) | Large batches, fried chicken, juicy meats |

Introduction to Deep-Frying and Pressure-Frying

Deep-frying involves submerging food in hot oil at temperatures typically between 325degF and 375degF, creating a crispy exterior and moist interior. Pressure-frying cooks food under pressure with hot oil, maintaining moisture while reducing cooking time and oil absorption.

Both methods use high temperatures and oil but differ in cooking dynamics and equipment requirements. Pressure-frying is often used in commercial kitchens to produce juicier, less greasy fried foods compared to traditional deep-frying.

How Deep-Frying Works: Method and Science

Deep-frying cooks food by submerging it in hot oil, typically between 350degF and 375degF, which rapidly transfers heat to the food's surface. This method causes the Maillard reaction, creating a crispy, golden-brown exterior while sealing moisture inside. Unlike pressure-frying, deep-frying relies solely on oil temperature and immersion time without altering atmospheric pressure to influence cooking speed or texture.

Pressure-Frying Explained: The Process Unveiled

| Pressure-frying involves cooking food inside a sealed pressure vessel at high temperatures and pressure, resulting in faster cooking times compared to traditional deep-frying. The pressurized environment enhances heat transfer, ensuring juicier and more tender results, particularly with poultry. This method retains moisture better and reduces oil absorption, leading to a crispier exterior and a more flavorful interior. |

Key Equipment Needed for Deep-Frying vs Pressure-Frying

Deep-frying requires essential equipment such as a deep fryer or heavy-duty pot, a thermometer to monitor oil temperature, and a slotted spoon or frying basket for safely handling food. Pressure-frying demands specialized pressure fryers equipped with sealed lids and pressure control systems to maintain optimal cooking conditions.

Deep fryers are typically open-vessel appliances that allow oil temperatures to be easily adjusted and monitored, ideal for frying at high heat around 350-375degF. Pressure fryers operate under higher pressure, enabling food to cook faster while retaining moisture, but they require more complex safety features and robust construction. Both methods need high-quality, heat-stable cooking oil and reliable tools to ensure efficient and safe food preparation.

Flavor Differences: Taste and Texture Comparisons

Deep-frying produces a crispy, golden exterior with a lighter, airier texture, enhancing the natural flavors of the food through high-temperature oil immersion. Pressure-frying uses a sealed environment that locks in moisture, resulting in juicier, more tender meat with a richer, more intense flavor profile. The controlled pressure and temperature create a unique combination of crispiness and succulence, making pressure-fried foods distinctly different from traditional deep-fried dishes.

Health and Nutrition: Oil Absorption and Calorie Count

Deep-frying typically results in higher oil absorption, increasing calorie content compared to pressure-frying. Pressure-frying uses higher pressure to cook food faster, reducing oil penetration and overall fat content.

- Oil Absorption - Pressure-frying minimizes oil uptake by cooking food quickly under pressure, while deep-frying allows more oil to penetrate.

- Calorie Count - Foods prepared with pressure-frying generally contain fewer calories due to reduced fat absorption.

- Health Impact - Lower oil content in pressure-fried foods can contribute to healthier meal options with less risk of unhealthy fat consumption.

Cooking Times and Temperature Control

Deep-frying typically requires higher temperatures around 350-375degF and longer cooking times to achieve a crispy exterior. Pressure-frying cooks at lower temperatures, 250-300degF, but significantly reduces cooking time by using pressurized steam.

- Deep-frying temperature control - Precise heat monitoring is crucial to maintain 350-375degF for optimal crispiness and thorough cooking.

- Pressure-frying temperature control - Lower temperatures prevent burning while pressure cooking accelerates heat penetration.

- Cooking time differences - Deep-frying can take up to twice as long compared to pressure-frying for similar results.

Pressure-frying offers more efficient cooking with better moisture retention by combining lower temperature and reduced time.

Safety Concerns and Best Practices

What are the key safety concerns when comparing deep-frying to pressure-frying? Deep-frying carries higher risks of oil splatters and burns due to exposed hot oil, requiring careful temperature control and use of protective gear. Pressure-frying reduces oil exposure with a sealed environment, minimizing accidents but demands regular equipment maintenance to prevent pressure-related hazards.

Cost and Efficiency in Home and Commercial Kitchens

Deep-frying requires less specialized equipment and lower initial investment, making it more cost-effective for home kitchens. It consumes more oil over time, increasing operating costs in commercial settings compared to pressure-frying.

Pressure-frying uses higher pressure to cook food faster, improving energy efficiency and reducing cooking time in commercial kitchens. Despite higher upfront equipment costs, pressure-frying lowers oil absorption and extends oil life, resulting in long-term savings and consistent food quality.

Related Important Terms

Low-Oil Immersion Frying

Low-oil immersion frying combines the high heat and fast cooking of deep-frying with reduced oil usage, offering a healthier alternative without sacrificing crispiness or flavor. This method uses pressure-frying principles to decrease oil absorption and cooking time, resulting in less greasy and more evenly cooked foods.

Broaster Technique

The Broaster technique combines pressure frying and traditional deep-frying to cook chicken faster while retaining juiciness and crispiness through sealed high-pressure cooking at around 35 psi and 350degF oil temperature. Pressure frying reduces oil absorption and cooking time compared to conventional deep-frying methods, making it a preferred technique for commercial and restaurant-quality fried chicken.

Turbo Pressure Frying

Turbo pressure frying combines the high heat of deep-frying with pressure cooking, significantly reducing cooking time while ensuring food retains moisture and flavor. This method yields crispy textures similar to traditional deep-frying but with less oil absorption and improved efficiency, making it ideal for commercial kitchens seeking faster, consistent results.

Flash-Fry Crisping

Deep-frying achieves flash-fry crisping by submerging food in hot oil at temperatures typically between 350degF and 375degF, rapidly dehydrating the surface to form a golden, crunchy crust. Pressure-frying maintains higher pressure inside the vessel, allowing cooking at slightly higher temperatures without burning, resulting in juicier interiors but a less intense flash-fry crispiness compared to traditional deep-frying.

Vacuum Frying

Vacuum frying, unlike traditional deep-frying or pressure-frying, uses low pressure and reduced oxygen levels to cook food at lower temperatures, preserving nutrients and natural colors while minimizing oil absorption. This method enhances flavor retention and produces healthier, crispier snacks compared to the higher temperature and oxygen exposure involved in deep-frying or the rapid cooking environment of pressure-frying.

Hyper-Pressure Oil Infusion

Hyper-pressure oil infusion during pressure-frying enhances flavor absorption and moisture retention by cooking food under high pressure, resulting in juicier, more tender dishes compared to traditional deep-frying. This advanced method reduces oil viscosity and accelerates heat transfer, significantly improving texture and reducing cooking time while maintaining crispiness.

Multi-Stage Fry Profiles

Deep-frying employs consistent high temperatures around 350-375degF (175-190degC) to achieve uniform crispness, whereas pressure-frying combines high temperature with increased pressure, typically around 15 psi, resulting in faster cooking times and juicier food. Multi-stage fry profiles in deep-frying optimize texture by varying temperature and duration, but pressure-frying's sealed environment allows for a single-stage process with enhanced moisture retention and flavor infusion.

Oil Rollover Rate

Deep-frying typically has a higher oil rollover rate compared to pressure-frying, resulting in greater oil absorption and increased fat content in foods. Pressure-frying reduces oil rollover by maintaining higher pressure and temperature, enhancing heat transfer efficiency and producing crisper, less greasy products.

Fryer Thermal Recovery

Deep-frying relies on open hot oil exposing food to high temperatures, resulting in slower thermal recovery due to heat loss during batch loading. Pressure-frying uses a sealed environment that maintains consistent heat and pressure, significantly improving fryer thermal recovery and reducing cooking time while retaining moisture and flavor.

Deep-frying vs Pressure-frying for cooking. Infographic

cookingdiff.com

cookingdiff.com