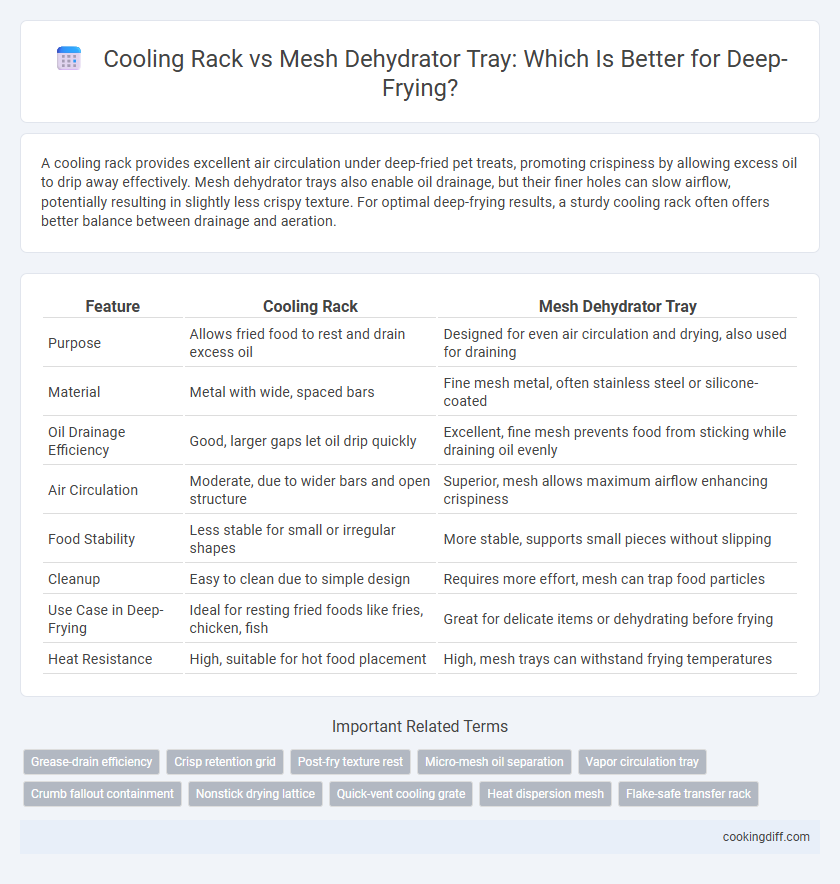

A cooling rack provides excellent air circulation under deep-fried pet treats, promoting crispiness by allowing excess oil to drip away effectively. Mesh dehydrator trays also enable oil drainage, but their finer holes can slow airflow, potentially resulting in slightly less crispy texture. For optimal deep-frying results, a sturdy cooling rack often offers better balance between drainage and aeration.

Table of Comparison

| Feature | Cooling Rack | Mesh Dehydrator Tray |

|---|---|---|

| Purpose | Allows fried food to rest and drain excess oil | Designed for even air circulation and drying, also used for draining |

| Material | Metal with wide, spaced bars | Fine mesh metal, often stainless steel or silicone-coated |

| Oil Drainage Efficiency | Good, larger gaps let oil drip quickly | Excellent, fine mesh prevents food from sticking while draining oil evenly |

| Air Circulation | Moderate, due to wider bars and open structure | Superior, mesh allows maximum airflow enhancing crispiness |

| Food Stability | Less stable for small or irregular shapes | More stable, supports small pieces without slipping |

| Cleanup | Easy to clean due to simple design | Requires more effort, mesh can trap food particles |

| Use Case in Deep-Frying | Ideal for resting fried foods like fries, chicken, fish | Great for delicate items or dehydrating before frying |

| Heat Resistance | High, suitable for hot food placement | High, mesh trays can withstand frying temperatures |

Introduction: Cooling Rack vs Mesh Dehydrator Tray for Deep-Frying

Deep-frying requires efficient oil drainage and cooling to maintain food crispiness. Choosing between a cooling rack and a mesh dehydrator tray impacts the texture and oil retention of fried foods.

- Cooling Rack - Elevates food for air circulation, preventing sogginess by allowing excess oil to drip off easily.

- Mesh Dehydrator Tray - Features a fine grid that supports smaller items and promotes even cooling through superior airflow.

- Material and Design - Stainless steel constructions enhance durability and resist warping under high temperatures during deep-frying.

Selecting the right tool depends on the fried food's size and desired crispiness level.

Purpose and Functionality in Deep-Frying

Cooling racks allow excess oil to drip away from fried foods, preserving crispiness and preventing sogginess. Mesh dehydrator trays promote even air circulation to enhance crisp texture during the cooling process.

- Cooling Rack - Supports food above a surface to drain oil efficiently after deep-frying.

- Mesh Dehydrator Tray - Features fine mesh to allow airflow around smaller food pieces, aiding uniform drying.

- Functionality Contrast - Cooling racks prioritize oil drainage, while mesh trays focus on air exposure to maintain texture.

Heat Resistance and Durability

Cooling racks typically offer superior heat resistance with materials like stainless steel that withstand high frying temperatures without warping. Mesh dehydrator trays often have lower heat thresholds and may degrade faster under constant exposure to extreme heat during deep-frying.

- Cooling racks are designed to handle high temperatures - They are usually made from durable stainless steel alloys that resist bending and corrosion during intensive heat exposure.

- Mesh dehydrator trays may have limited heat tolerance - Constructed from lighter metals or coated materials, they risk warping or coating degradation when exposed to deep-frying temperatures above 350degF (177degC).

- Durability over repeated use favors cooling racks - Their robust construction ensures longevity and consistent performance in heat-intensive cooking processes like deep-frying.

Oil Drainage Efficiency

Cooling racks with larger gaps allow excess oil to drain quickly, reducing residual grease on deep-fried foods. Mesh dehydrator trays have finer grids that slow oil drainage but can support smaller or delicate items without slipping. Optimizing oil drainage efficiency depends on the food type and desired crispiness, with cooling racks typically offering superior drainage for larger pieces.

Ease of Cleaning and Maintenance

Which option offers easier cleaning and maintenance after deep-frying: a cooling rack or a mesh dehydrator tray? Cooling racks typically have fewer crevices, making them simpler to wipe down and less prone to trapped grease. Mesh dehydrator trays require thorough scrubbing due to their fine grid, which can accumulate oil and food particles more easily.

Food Safety Considerations

Using a cooling rack for deep-fried foods allows excess oil to drip away, reducing grease accumulation and minimizing the risk of bacterial growth caused by trapped moisture. Its elevated design promotes air circulation, helping foods cool evenly and safely.

Mesh dehydrator trays, while effective for airflow, can trap small food particles and oil residues, potentially creating a breeding ground for bacteria if not cleaned thoroughly. Ensuring both tools are sanitized regularly is crucial to maintain food safety standards and prevent contamination.

Versatility in the Kitchen

Cooling racks provide excellent airflow, allowing excess oil to drip away from fried foods, promoting crispiness and preventing sogginess during cooling. Their elevated design fits various pan sizes, making them versatile for tasks beyond deep-frying, such as baking and roasting.

Mesh dehydrator trays offer finer support for smaller items and enable dehydration alongside cooling, adding multifunctionality for snack preparation. Their compact, stackable design is ideal for space-saving in kitchens focused on both frying and preserving food.

Space Optimization and Storage

| Cooling Rack | Cooling racks are typically compact with stackable options, allowing efficient use of vertical space for storage and cooling multiple batches simultaneously. |

| Mesh Dehydrator Tray | Mesh dehydrator trays are designed to be lightweight and stackable but require more horizontal space due to their flat design, making them less optimal for tight storage areas. |

| Space Optimization | Cooling racks optimize space vertically, making them ideal for kitchens with limited counter areas, while mesh trays maximize airflow but demand larger flat surfaces. |

| Storage | Cooling racks can be nested or folded for compact storage, whereas mesh dehydrator trays are stored in stacks that may be bulkier and occupy more shelf space. |

Affordability and Availability

Cooling racks are widely available and generally more affordable than mesh dehydrator trays, making them a popular choice for home deep-frying. These racks often fit standard baking sheets, increasing their convenience and accessibility in most kitchens.

Mesh dehydrator trays tend to be pricier and less common, primarily found in specialty stores or online. They offer superior airflow for crispier results but require a more significant investment upfront. Considering budget and availability, cooling racks provide a practical, cost-effective solution for everyday deep-frying needs.

Related Important Terms

Grease-drain efficiency

Cooling racks with angled grids allow grease to drip directly into trays, enhancing grease-drain efficiency during deep-frying, while mesh dehydrator trays often trap oil due to their finer mesh structure. Optimal grease drainage reduces sogginess, making cooling racks the preferred choice for maintaining crispy textures in fried foods.

Crisp retention grid

A cooling rack with wider, sturdier bars allows hot oil to drip away efficiently while maintaining crisp retention by preventing sogginess during cooling. In contrast, a mesh dehydrator tray's finer grid may trap oil beneath fried foods, leading to less effective crisp retention and potential moisture buildup.

Post-fry texture rest

A cooling rack's elevated grid design allows excess oil to drip away effectively, promoting a crisp post-fry texture by preventing sogginess. Mesh dehydrator trays also facilitate air circulation but may retain more residual oil, potentially impacting the ideal crispness of deep-fried foods during the resting phase.

Micro-mesh oil separation

Micro-mesh oil separation on mesh dehydrator trays effectively drains excess oil from deep-fried foods, enhancing crispiness and reducing oil retention. Cooling racks, while useful for airflow, often lack the fine mesh needed to efficiently separate oil at the micro level, resulting in greasier textures.

Vapor circulation tray

A vapor circulation tray enhances deep-frying by allowing hot air and steam to circulate evenly around fried foods, resulting in crispier and less greasy textures compared to traditional cooling racks or mesh dehydrator trays. Its design minimizes sogginess by preventing moisture buildup, optimizing the quality and texture of deep-fried items.

Crumb fallout containment

Cooling racks with tight grids effectively contain crumb fallout during deep-frying by allowing excess oil to drip while preventing small crumbs from falling through. Mesh dehydrator trays, featuring finer perforations, offer superior crumb containment and airflow, minimizing mess and promoting even oil drainage.

Nonstick drying lattice

A nonstick drying lattice on a mesh dehydrator tray provides superior airflow and even oil drainage compared to a cooling rack, preventing sogginess in deep-fried foods. The fine mesh construction minimizes oil buildup and ensures quicker, more uniform cooling without sticking, enhancing crispiness and texture.

Quick-vent cooling grate

A quick-vent cooling grate provides superior airflow compared to standard mesh dehydrator trays, allowing deep-fried foods to drain excess oil rapidly and maintain their crispiness. Its elevated design prevents sogginess by promoting even cooling and efficient oil runoff, enhancing texture retention during post-frying rest.

Heat dispersion mesh

A cooling rack with heat dispersion mesh allows hot oil to drain efficiently during deep-frying, preventing sogginess and promoting crispiness through optimal airflow. In contrast, a mesh dehydrator tray offers finer mesh that enhances even heat distribution but may retain more oil, affecting the final texture of fried foods.

Cooling rack vs mesh dehydrator tray for deep-frying. Infographic

cookingdiff.com

cookingdiff.com