A traditional thermometer provides accurate internal temperature readings essential for deep-frying pet treats, ensuring they are cooked safely and thoroughly. Infrared thermometers measure surface temperature quickly but may not reflect the oil's actual heat or the pet food's internal temperature. For precise control and safety in deep-frying pet food, a probe thermometer is generally more reliable.

Table of Comparison

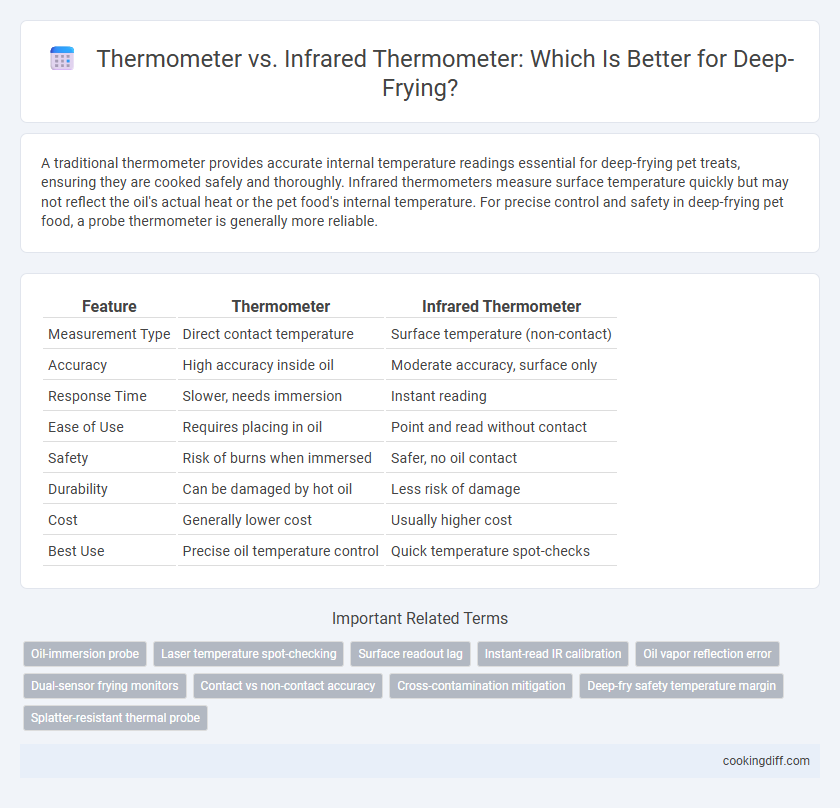

| Feature | Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Type | Direct contact temperature | Surface temperature (non-contact) |

| Accuracy | High accuracy inside oil | Moderate accuracy, surface only |

| Response Time | Slower, needs immersion | Instant reading |

| Ease of Use | Requires placing in oil | Point and read without contact |

| Safety | Risk of burns when immersed | Safer, no oil contact |

| Durability | Can be damaged by hot oil | Less risk of damage |

| Cost | Generally lower cost | Usually higher cost |

| Best Use | Precise oil temperature control | Quick temperature spot-checks |

Introduction: The Importance of Accurate Temperature in Deep-Frying

Maintaining precise oil temperature is critical for achieving the perfect deep-fried texture and flavor while ensuring safety. Both traditional and infrared thermometers offer distinct advantages for monitoring frying temperatures.

- Thermometer - Immerses directly in oil to provide accurate, real-time temperature readings essential for consistent cooking.

- Infrared Thermometer - Measures surface temperature without contact, ideal for quick checks but may not reflect oil's internal heat accurately.

- Temperature Precision - Correct temperature control prevents oil degradation and food absorption of excess grease, improving taste and health.

Choosing the right thermometer type enhances frying outcomes by optimizing heat control and food quality.

Understanding Traditional Deep-Fry Thermometers

Traditional deep-fry thermometers are designed to clip onto the side of a pot, providing continuous temperature readings between 200degF and 400degF, essential for maintaining optimal frying heat. Their metal probes offer direct contact with oil, resulting in accurate and reliable temperature monitoring during the deep-frying process.

Infrared thermometers measure surface temperature without contact, which can be less precise for hot oil that requires internal temperature readings. Understanding the limitations of infrared devices highlights why traditional deep-fry thermometers remain the preferred tool for achieving consistent frying results.

What Is an Infrared Thermometer?

An infrared thermometer measures surface temperature by detecting infrared radiation emitted from the oil, providing a quick and non-contact reading during deep-frying. Unlike traditional thermometers that must be submerged in oil, infrared thermometers help maintain safety by avoiding direct contact with hot oil. However, they may not always reflect the exact internal temperature of the oil, making them less accurate for precise temperature control.

How Each Thermometer Measures Oil Temperature

Traditional deep-frying thermometers measure the oil temperature by immersion, providing a direct and accurate reading of the oil's internal heat. Infrared thermometers measure surface temperature from a distance, detecting the heat emitted by the oil's surface without contact.

- Immersion Precision - A conventional thermometer is submerged into the oil to gauge the exact temperature at the cook zone.

- Surface Measurement - Infrared thermometers read the thermal radiation emitted from the oil's upper layer to estimate temperature.

- Temperature Depth - Immersion thermometers provide temperature readings throughout the oil, while infrared devices only reflect surface conditions.

Accuracy: Traditional vs. Infrared Thermometers

| Thermometer Type | Accuracy | Best Use in Deep-Frying |

|---|---|---|

| Traditional Deep-Fry Thermometer | Highly accurate when fully submerged in oil, providing precise oil temperature readings essential for crispy, evenly cooked food. | Ideal for continuous temperature monitoring throughout the deep-frying process. |

| Infrared Thermometer | Measures surface temperature quickly but may not accurately reflect the oil temperature beneath the surface, prone to variance due to reflections and splatters. | Best for quick checks of oil surface temperature but less reliable for maintaining consistent frying temperatures. |

Speed and Convenience During Deep-Frying

Thermometers with probe sensors provide accurate and continuous temperature readings essential for maintaining ideal deep-frying heat levels. Infrared thermometers offer rapid surface temperature measurements without contact, enhancing speed and safety during frying. Each tool improves convenience, but probe thermometers ensure precise oil temperature control critical for consistent frying results.

Safety and Ease of Use

Traditional deep-frying thermometers provide precise temperature readings by direct contact with the oil, ensuring accurate monitoring for safe cooking. Their design often includes clips for easy attachment to pots, allowing continuous temperature checks without immersion.

Infrared thermometers enable quick, non-contact temperature measurements, reducing the risk of burns and oil splashes during deep-frying. However, their readings can be less accurate for deep oil temperatures, requiring careful aiming and consideration of surface reflections to maintain safety.

Versatility in the Kitchen

Traditional deep-fry thermometers offer precise oil temperature readings critical for consistent cooking results, especially when submerged directly into hot oil. Infrared thermometers provide quick surface temperature measurements but may not accurately reflect the oil's internal heat.

Traditional thermometers excel in versatility by allowing monitoring of liquids and foods during the cooking process, essential for deep-frying various ingredients. Infrared thermometers are useful for quickly scanning pans and oil surfaces but do not measure internal temperatures, limiting their reliability for deep-frying. Combining both tools can enhance kitchen efficiency and cooking accuracy.

Maintenance and Durability

Which thermometer is more durable and easier to maintain for deep-frying? Traditional deep-frying thermometers often feature robust metal construction that withstands high temperatures and frequent oil exposure, making them easier to clean and less prone to damage. Infrared thermometers require careful calibration and protection from oil splatters, which can affect sensor accuracy and longevity over time.

Related Important Terms

Oil-immersion probe

An oil-immersion probe thermometer provides more accurate and consistent temperature readings for deep-frying by being directly submerged in the hot oil, unlike infrared thermometers, which only measure surface temperatures and can be affected by steam and splatter. This precision ensures optimal cooking temperatures are maintained, enhancing food quality and safety by preventing undercooking or oil degradation.

Laser temperature spot-checking

Infrared thermometers offer precise laser temperature spot-checking ideal for quickly measuring the surface heat of oil during deep-frying, ensuring optimal cooking temperatures without direct contact. Traditional thermometers provide accurate ambient oil temperature readings but lack the instant, pinpoint accuracy and convenience of laser-guided infrared devices for monitoring hot oil.

Surface readout lag

Traditional thermometers provide accurate internal temperature readings essential for deep-frying but exhibit a slower surface readout lag, delaying precise oil temperature adjustments. Infrared thermometers offer instant surface temperature measurements, minimizing lag and improving real-time monitoring, though they may not reflect the actual oil temperature beneath the surface.

Instant-read IR calibration

Instant-read infrared thermometers provide rapid surface temperature readings crucial for maintaining optimal deep-frying oil heat, but they require frequent calibration against probe thermometers to ensure accuracy due to potential emissivity variations. Precision probe thermometers measure internal oil temperature directly, offering consistent reliability for deep-frying, though they lack the instant-read convenience of infrared devices.

Oil vapor reflection error

Traditional deep-frying thermometers provide accurate oil temperature readings by direct immersion, avoiding errors caused by oil vapor reflection that infrared thermometers often encounter. Infrared thermometers measure surface temperature remotely, with oil vapor creating reflective interference that leads to inaccurate and inconsistent readings during deep-frying.

Dual-sensor frying monitors

Dual-sensor frying monitors combine traditional probe thermometers with infrared sensors to provide precise temperature readings both below and above the oil surface, ensuring optimal deep-frying conditions. These monitors enhance cooking accuracy by detecting oil temperature fluctuations rapidly and minimizing overcooking or undercooking risks.

Contact vs non-contact accuracy

A traditional probe thermometer provides superior accuracy for deep-frying by measuring the oil temperature through direct contact, ensuring precise readings that reflect the oil's true heat. Infrared thermometers offer non-contact convenience but can be less reliable for deep-frying due to surface temperature fluctuations and reflections affecting their accuracy.

Cross-contamination mitigation

Using a probe thermometer for deep-frying ensures direct contact temperature measurement, reducing the risk of cross-contamination compared to infrared thermometers that only gauge surface heat without touching the oil. Properly sanitizing probe thermometers between uses further mitigates bacterial transfer, making them more reliable for safe frying practices.

Deep-fry safety temperature margin

A probe thermometer provides accurate, real-time measurements of oil temperature, ensuring deep-fry safety margins are maintained to prevent overheating and potential fire hazards. Infrared thermometers offer quick surface readings but can miss internal oil temperature fluctuations critical for safe deep-frying.

Thermometer vs infrared thermometer for deep-frying. Infographic

cookingdiff.com

cookingdiff.com