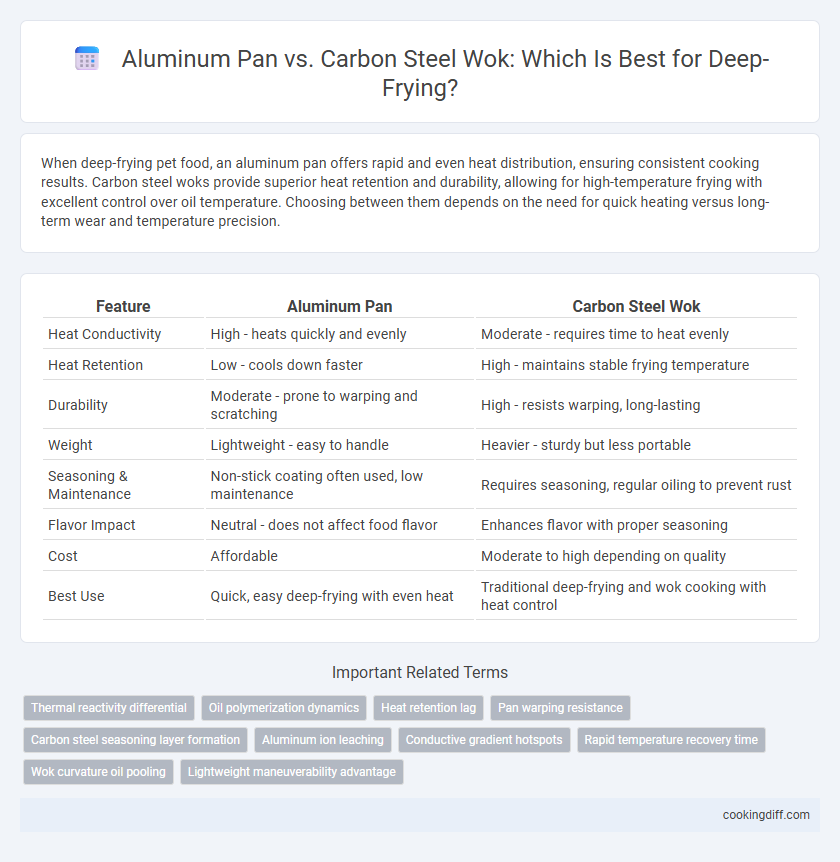

When deep-frying pet food, an aluminum pan offers rapid and even heat distribution, ensuring consistent cooking results. Carbon steel woks provide superior heat retention and durability, allowing for high-temperature frying with excellent control over oil temperature. Choosing between them depends on the need for quick heating versus long-term wear and temperature precision.

Table of Comparison

| Feature | Aluminum Pan | Carbon Steel Wok |

|---|---|---|

| Heat Conductivity | High - heats quickly and evenly | Moderate - requires time to heat evenly |

| Heat Retention | Low - cools down faster | High - maintains stable frying temperature |

| Durability | Moderate - prone to warping and scratching | High - resists warping, long-lasting |

| Weight | Lightweight - easy to handle | Heavier - sturdy but less portable |

| Seasoning & Maintenance | Non-stick coating often used, low maintenance | Requires seasoning, regular oiling to prevent rust |

| Flavor Impact | Neutral - does not affect food flavor | Enhances flavor with proper seasoning |

| Cost | Affordable | Moderate to high depending on quality |

| Best Use | Quick, easy deep-frying with even heat | Traditional deep-frying and wok cooking with heat control |

Introduction to Deep-Frying: Choosing the Right Cookware

Choosing the right cookware is essential for effective deep-frying, influencing heat distribution and cooking results. Aluminum pans and carbon steel woks are popular options, each offering unique advantages for deep-frying techniques.

- Aluminum Pan - Lightweight with excellent heat conductivity, allowing for quick and even heating during deep-frying.

- Carbon Steel Wok - Known for superior heat retention and rapid temperature recovery, ideal for maintaining consistent frying heat.

- Durability and Maintenance - Aluminum pans are prone to warping and require careful use, while carbon steel woks develop a natural non-stick patina with proper seasoning and care.

Aluminum Pan vs Carbon Steel Wok: Material Properties Overview

Aluminum pans offer excellent thermal conductivity, ensuring even heat distribution crucial for deep-frying, but they may warp at high temperatures. Carbon steel woks provide superior heat retention and develop a natural non-stick surface with seasoning, ideal for consistent high-heat frying. Both materials require proper maintenance: aluminum pans resist rust but can react with acidic foods, while carbon steel woks need regular seasoning to prevent rust and maintain performance.

Heat Conductivity: Aluminum Pan vs Carbon Steel Wok

Aluminum pans offer excellent heat conductivity, allowing for rapid and even heat distribution essential for consistent deep-frying results. Carbon steel woks heat up quickly but have slightly lower thermal conductivity, leading to some temperature variations across the cooking surface.

The superior heat retention of carbon steel woks helps maintain steady oil temperature during prolonged frying, reducing food absorption of excess oil. Aluminum pans cool rapidly once food is added, requiring careful heat adjustments to avoid temperature drops. Both materials demand attentive temperature control, but carbon steel woks provide better thermal stability for deep-frying at high temperatures.

Heat Retention and Temperature Stability

Aluminum pans heat up quickly but have lower heat retention compared to carbon steel woks, which maintain temperature more consistently during deep-frying. Carbon steel woks offer superior temperature stability, ensuring even cooking and better control over oil temperature.

- Aluminum pans heat rapidly - Aluminum's high thermal conductivity allows for quick heating but loses heat faster.

- Carbon steel retains heat better - The thicker material of carbon steel stores and maintains heat for more consistent frying temperatures.

- Temperature stability - Carbon steel woks resist temperature drops when adding food, resulting in less oil absorption and crispier results.

Oil Usage and Capacity Differences

Aluminum pans heat up quickly and distribute heat evenly, allowing for efficient oil usage during deep-frying, but their limited depth can restrict oil capacity. Carbon steel woks, with their larger surface area and curved shape, hold more oil, making them ideal for frying larger quantities or bigger food items.

Due to the thicker construction of carbon steel woks, they retain heat longer, reducing the need for excessive oil replenishment during cooking. Aluminum pans, being lighter, cool down faster, which may require more frequent oil temperature adjustments and additional oil to maintain frying consistency.

Food Texture and Flavor Impact

Aluminum pans heat quickly and evenly, promoting a consistent crispiness in deep-fried foods, but they may impart a slightly metallic taste. Carbon steel woks develop a natural seasoning over time, enhancing flavor complexity and contributing to a superior, crunchy texture in fried dishes. The high heat retention of carbon steel allows for better moisture control, resulting in a more satisfying, golden-brown finish compared to aluminum pans.

Ease of Use and Handling

| Cookware Type | Ease of Use | Handling |

|---|---|---|

| Aluminum Pan | Lightweight structure allows easy maneuvering and quick heating for efficient deep-frying. | Non-reactive surface minimizes sticking, but can warp under high heat if thin; handles usually stay cool. |

| Carbon Steel Wok | Heats evenly with high heat retention, requiring seasoning to maintain non-stick properties for consistent frying. | Heavier than aluminum pans, often features long handles and helper grips for better control during frying. |

Maintenance and Longevity

Which cookware offers better maintenance and longevity for deep-frying, aluminum pans or carbon steel woks? Carbon steel woks require regular seasoning to maintain their non-stick surface and prevent rust, but this upkeep extends their lifespan significantly. Aluminum pans are easier to clean and require less maintenance, yet they tend to degrade faster and may warp under high heat conditions common in deep-frying.

Safety Considerations for Deep-Frying

Aluminum pans heat quickly but may warp at high temperatures, posing a risk during deep-frying. Carbon steel woks distribute heat evenly and retain high temperatures safely without deformation.

- Heat Resistance - Carbon steel tolerates high heat better than aluminum, reducing the chance of structural failure.

- Durability - Aluminum pans can bend or degrade with repeated exposure to hot oil, while carbon steel provides long-lasting sturdiness.

- Reactivity - Aluminum may react with acidic foods, potentially releasing harmful compounds during deep-frying, unlike inert carbon steel.

Choosing carbon steel woks can enhance safety by providing stable temperature control and material integrity for deep-frying.

Related Important Terms

Thermal reactivity differential

Aluminum pans heat up rapidly due to their high thermal conductivity, providing quick temperature recovery ideal for consistent deep-frying, while carbon steel woks offer moderate heat retention and a more gradual temperature increase that prevents overheating and maintains oil stability. The thermal reactivity differential between aluminum and carbon steel significantly affects cooking efficiency and food texture during deep-frying processes.

Oil polymerization dynamics

Aluminum pans heat quickly but can lead to uneven oil polymerization during deep-frying, causing inconsistent non-stick layers and accelerated oil breakdown. Carbon steel woks maintain higher, stable temperatures that promote uniform oil polymerization, enhancing the seasoning layer and improving oil longevity for better frying performance.

Heat retention lag

Aluminum pans heat up quickly but suffer from poor heat retention lag, causing temperature fluctuations during deep-frying that can lead to uneven cooking. Carbon steel woks, with superior heat retention lag, maintain consistent high temperatures, ensuring crispier and evenly fried food.

Pan warping resistance

Carbon steel woks offer superior pan warping resistance compared to aluminum pans due to their thicker construction and higher heat tolerance, making them ideal for stable deep-frying at high temperatures. Aluminum pans, while lightweight and quick to heat, are more prone to warping under intense heat cycles, which can affect cooking consistency and safety.

Carbon steel seasoning layer formation

Carbon steel woks develop a natural seasoning layer through repeated heating and oil polymerization, creating a non-stick, rust-resistant surface ideal for deep-frying. Unlike aluminum pans, which lack seasoning properties, carbon steel's patina enhances heat retention and imparts superior flavor while reducing oil absorption.

Aluminum ion leaching

Aluminum pans, while excellent for heat conduction in deep-frying, pose a risk of aluminum ion leaching into food, especially when cooking acidic or high-salt dishes, potentially affecting flavor and health. Carbon steel woks provide superior durability and chemical stability, minimizing aluminum ion contamination and maintaining food safety during prolonged high-temperature frying.

Conductive gradient hotspots

Carbon steel woks offer superior heat conduction with evenly distributed temperature and fewer gradient hotspots, making them ideal for consistent deep-frying. Aluminum pans heat quickly but often develop uneven hotspots that can cause inconsistent cooking and oil temperature fluctuations.

Rapid temperature recovery time

Aluminum pans excel in rapid temperature recovery during deep-frying due to aluminum's high thermal conductivity, allowing oil to quickly return to optimal frying temperatures after food is added. Carbon steel woks, while heat quicker initially, have a slightly slower temperature rebound compared to aluminum but provide superior heat retention for consistent frying results.

Wok curvature oil pooling

Carbon steel woks feature a rounded curvature that promotes even oil pooling, essential for consistent deep-frying temperatures, while aluminum pans with flat bases may cause uneven oil distribution, affecting heat retention and frying quality. The wok's design minimizes oil usage and enhances heat circulation, making it superior for traditional deep-frying techniques requiring precise temperature control.

Aluminum pan vs carbon steel wok for deep-frying. Infographic

cookingdiff.com

cookingdiff.com