Deep-frying transfers heat through complete immersion of food in hot oil, ensuring rapid and uniform cooking by surrounding the food with a consistent high temperature. Stir-frying, on the other hand, relies on direct contact with a hot pan surface and constant movement, leading to quicker moisture evaporation and varying heat distribution. The key difference lies in the medium of heat transfer: oil immersion in deep-frying versus conductive heat from the pan in stir-frying.

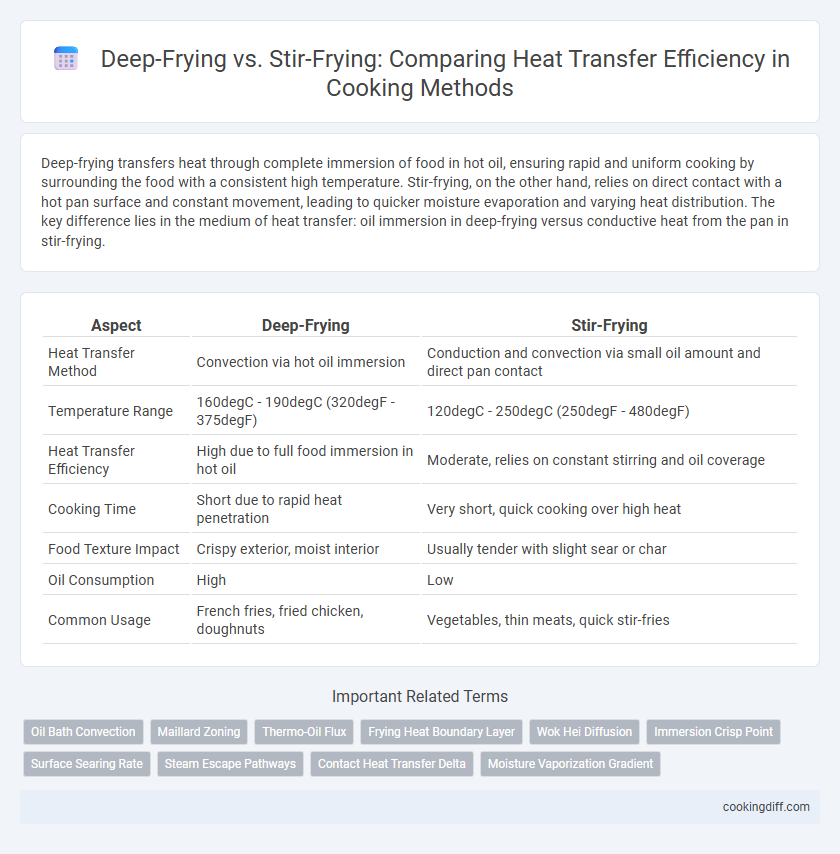

Table of Comparison

| Aspect | Deep-Frying | Stir-Frying |

|---|---|---|

| Heat Transfer Method | Convection via hot oil immersion | Conduction and convection via small oil amount and direct pan contact |

| Temperature Range | 160degC - 190degC (320degF - 375degF) | 120degC - 250degC (250degF - 480degF) |

| Heat Transfer Efficiency | High due to full food immersion in hot oil | Moderate, relies on constant stirring and oil coverage |

| Cooking Time | Short due to rapid heat penetration | Very short, quick cooking over high heat |

| Food Texture Impact | Crispy exterior, moist interior | Usually tender with slight sear or char |

| Oil Consumption | High | Low |

| Common Usage | French fries, fried chicken, doughnuts | Vegetables, thin meats, quick stir-fries |

Introduction to Deep-Frying and Stir-Frying

Deep-frying involves submerging food in hot oil, typically between 350degF and 375degF, enabling rapid and even heat transfer through convection, resulting in a crispy exterior and moist interior. Stir-frying uses a small amount of oil over high heat, with constant stirring to distribute heat mainly through conduction and some convection, producing quick cooking with minimal oil absorption. The high temperature and oil quantity in deep-frying create distinct textural and flavor outcomes compared to the faster, lower-fat method of stir-frying.

Overview of Heat Transfer Methods in Cooking

Deep-frying uses convection and conduction to transfer heat rapidly by submerging food in hot oil, ensuring even and consistent cooking. Stir-frying relies on conduction and convection through direct contact with a hot wok and frequent stirring, producing quicker but less uniform heat distribution. The high temperature oil in deep-frying enables faster Maillard reactions compared to the lower oil volume and temperature gradients in stir-frying.

Deep-Frying: Mechanisms of Heat Transfer

Deep-frying relies primarily on convection heat transfer, where hot oil uniformly surrounds the food, enabling rapid and even cooking. The high temperature of the oil causes moisture inside the food to vaporize quickly, creating a crispy outer layer while retaining internal juiciness.

- Convection Dominance - Hot oil circulates around the food, transferring heat efficiently through fluid motion.

- Rapid Moisture Vaporization - High oil temperature causes water inside food to vaporize, aiding in crust formation.

- Uniform Heat Distribution - Oil immersion ensures even surface heating compared to the localized heating in stir-frying.

Stir-Frying: How Heat Moves Through Food

Stir-frying utilizes direct contact between food and a hot cooking surface, allowing heat to transfer quickly through conduction. This method ensures rapid cooking of thinly sliced ingredients, preserving texture and nutrients.

Heat moves primarily through conduction from the wok or pan to the food's surface, then penetrates inward. Constant stirring and tossing expose different parts of the food to the heat source evenly, preventing burning or uneven cooking. The high heat and quick cooking time minimize moisture loss, resulting in crisp, flavorful dishes.

Comparison of Cooking Temperatures

Deep-frying utilizes oil temperatures typically between 350degF and 375degF, enabling rapid and uniform heat transfer through full immersion. Stir-frying employs pan temperatures ranging from 300degF to 400degF, relying on direct contact and constant stirring for heat distribution.

- Deep-frying maintains consistent heat - The oil bath ensures even cooking temperatures around the food.

- Stir-frying requires intermittent heat application - Heat depends on pan surface temperature and frequent stirring.

- Heat transfer efficiency differs - Deep-frying immerses food in hot oil, while stir-frying transfers heat via conduction from the pan.

Oil’s Role in Deep-Frying vs Stir-Frying

In deep-frying, oil fully immerses the food, allowing heat to transfer efficiently through convection, which cooks food quickly and evenly. The high temperature of oil in deep-frying creates a crispy exterior by rapidly evaporating moisture from the food's surface.

In stir-frying, oil serves as a thin coating that facilitates direct heat transfer from the pan to the food through conduction and some convection. The smaller amount of oil and shorter cooking time in stir-frying helps preserve the food's texture and nutrients while providing a subtle flavor enhancement.

Surface Contact and Food Texture Differences

Deep-frying involves submerging food in hot oil, ensuring even heat transfer through full surface contact, resulting in a crisp and crunchy texture. Stir-frying uses a small amount of oil and constant stirring, leading to partial surface contact and a tender, slightly charred finish.

- Surface Contact in Deep-frying - Food is completely surrounded by hot oil, maximizing heat transfer efficiency.

- Surface Contact in Stir-frying - Food only partially contacts oil and the pan, causing uneven heating.

- Texture Differences - Deep-fried foods develop a thick, crispy exterior, while stir-fried foods remain tender with slight caramelization.

The distinct heat transfer methods directly influence the final texture and flavor profile of the cooked food.

Speed and Efficiency of Heat Penetration

| Method | Heat Transfer Mechanism | Speed of Heat Penetration | Efficiency |

|---|---|---|---|

| Deep-frying | Conduction and Convection via Immersion in Hot Oil (Typically 160-190degC) | Rapid heat penetration due to full surface contact with hot oil, resulting in faster cooking times | High efficiency in transferring heat uniformly, minimizing cooking duration and ensuring even crust formation |

| Stir-frying | Conduction and Convection via Direct Contact with Hot Pan Surface and Stirring | Slower heat penetration as food contacts the pan intermittently with frequent movement | Moderate efficiency; requires continuous stirring to distribute heat evenly, leading to longer cooking times than deep-frying |

Nutrient Retention: Deep-Frying vs Stir-Frying

How does nutrient retention compare between deep-frying and stir-frying? Deep-frying typically results in greater nutrient loss due to higher temperatures and longer cooking times, which can degrade heat-sensitive vitamins like vitamin C and some B vitamins. Stir-frying preserves more nutrients, especially antioxidants and water-soluble vitamins, as it uses shorter cooking times and lower temperatures with continuous stirring that limits exposure to heat.

Related Important Terms

Oil Bath Convection

Deep-frying utilizes oil bath convection, allowing uniform heat transfer through immersion in hot oil at temperatures typically between 175degC and 190degC, resulting in faster cooking and a crispy texture. Stir-frying relies on direct heat conduction from the pan's surface with intermittent oil coating, producing uneven heat distribution and requiring constant agitation to prevent food from sticking or burning.

Maillard Zoning

Deep-frying ensures uniform heat transfer through complete oil immersion, creating extensive Maillard zoning with evenly browned, crispy surfaces. Stir-frying relies on high heat and constant movement, producing localized Maillard zones and uneven browning due to limited oil contact.

Thermo-Oil Flux

Deep-frying achieves higher thermo-oil flux due to complete food submersion in hot oil, enhancing heat transfer efficiency compared to stir-frying's intermittent contact with the heated pan surface. This constant immersion in oil at temperatures typically between 160-190degC accelerates thermal conductivity, resulting in faster cooking times and more uniform heat distribution.

Frying Heat Boundary Layer

Deep-frying generates a thicker frying heat boundary layer due to full immersion in hot oil, enabling efficient and uniform heat transfer through convection and conduction. Stir-frying utilizes a thinner boundary layer with rapid agitation, which promotes quicker heat exchange but less uniform temperature distribution compared to deep-frying.

Wok Hei Diffusion

Deep-frying utilizes immersion in hot oil at temperatures typically between 160degC and 190degC, enabling rapid and uniform heat transfer through convection and conduction, resulting in a crispy texture and rich flavor. Stir-frying, often performed in a wok at high heat (around 200degC to 250degC), relies on continuous stirring and direct contact with the wok surface, promoting the formation of Wok Hei, a distinctive smoky aroma produced by the Maillard reaction and aromatic diffusion from intense localized heat.

Immersion Crisp Point

Deep-frying achieves superior heat transfer through complete immersion of food in hot oil, ensuring rapid and uniform cooking that reaches the Immersion Crisp Point effectively, creating a distinct crispy texture. Stir-frying relies on high heat and constant motion but lacks full immersion, resulting in less efficient heat penetration and a different crispness level.

Surface Searing Rate

Deep-frying achieves a higher surface searing rate than stir-frying due to complete immersion of food in hot oil at temperatures typically between 160-190degC, enabling rapid heat transfer via conduction and convection. Stir-frying relies mainly on direct contact with a hot pan surface, resulting in uneven heat distribution and slower surface searing compared to the consistent, surrounding heat in deep-frying.

Steam Escape Pathways

Deep-frying involves submerging food in hot oil, creating a uniform and efficient heat transfer environment that rapidly cooks the exterior while forming a crispy crust; steam generated inside the food escapes through porous pathways in the crust, preventing sogginess. In contrast, stir-frying relies on high heat and constant agitation in a small amount of oil, producing intermittent steam release through surface moisture evaporation rather than controlled escape pathways, which affects the texture and moisture retention differently.

Contact Heat Transfer Delta

Deep-frying offers higher contact heat transfer rates due to complete immersion of food in hot oil, facilitating rapid and uniform heat distribution compared to stir-frying, where food contacts a hot pan surface with intermittent oil. The contact heat transfer delta in deep-frying typically ranges between 300 to 600 W/m2*K, significantly surpassing the 50 to 150 W/m2*K seen in stir-frying, resulting in faster cooking times and distinct texture development.

Deep-frying vs Stir-frying for heat transfer Infographic

cookingdiff.com

cookingdiff.com