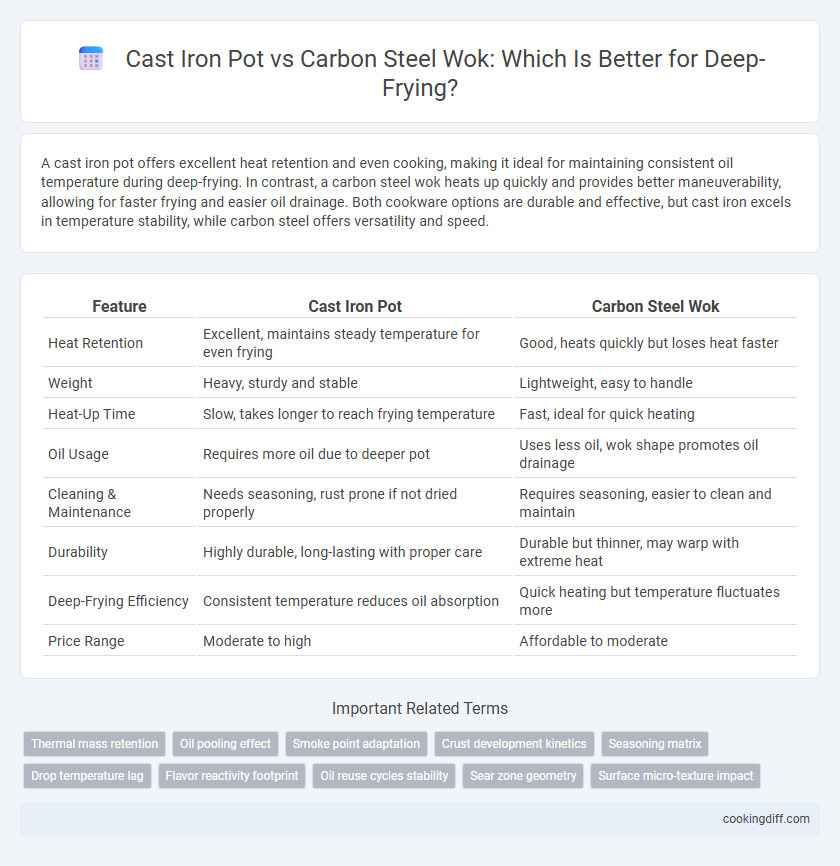

A cast iron pot offers excellent heat retention and even cooking, making it ideal for maintaining consistent oil temperature during deep-frying. In contrast, a carbon steel wok heats up quickly and provides better maneuverability, allowing for faster frying and easier oil drainage. Both cookware options are durable and effective, but cast iron excels in temperature stability, while carbon steel offers versatility and speed.

Table of Comparison

| Feature | Cast Iron Pot | Carbon Steel Wok |

|---|---|---|

| Heat Retention | Excellent, maintains steady temperature for even frying | Good, heats quickly but loses heat faster |

| Weight | Heavy, sturdy and stable | Lightweight, easy to handle |

| Heat-Up Time | Slow, takes longer to reach frying temperature | Fast, ideal for quick heating |

| Oil Usage | Requires more oil due to deeper pot | Uses less oil, wok shape promotes oil drainage |

| Cleaning & Maintenance | Needs seasoning, rust prone if not dried properly | Requires seasoning, easier to clean and maintain |

| Durability | Highly durable, long-lasting with proper care | Durable but thinner, may warp with extreme heat |

| Deep-Frying Efficiency | Consistent temperature reduces oil absorption | Quick heating but temperature fluctuates more |

| Price Range | Moderate to high | Affordable to moderate |

Introduction: Choosing the Right Vessel for Deep-Frying

| Cast iron pots provide excellent heat retention and even cooking, making them ideal for maintaining consistent oil temperature during deep-frying. |

| Carbon steel woks heat up rapidly and offer superior heat control, which is beneficial for quick temperature adjustments in deep-frying processes. |

| Choosing between a cast iron pot and a carbon steel wok depends on desired heat retention and responsiveness for optimal frying results. |

Material Composition: Cast Iron vs Carbon Steel

Cast iron pots are composed primarily of iron with a high carbon content, offering excellent heat retention and even heating ideal for deep-frying. Carbon steel woks consist of iron alloyed with a lower carbon percentage, making them lighter and quicker to heat compared to cast iron.

Cast iron's dense material structure provides slower heat response but superior heat maintenance, essential for consistent frying temperatures. Carbon steel's thinner composition ensures rapid heating and cooling, allowing more precise temperature control during deep-frying.

Heat Retention and Distribution

Which cookware offers better heat retention and distribution for deep-frying, a cast iron pot or a carbon steel wok? Cast iron pots excel in heat retention due to their dense material, maintaining consistent temperatures ideal for frying. Carbon steel woks heat up quickly and distribute heat evenly but may require constant temperature monitoring to prevent fluctuations during deep-frying.

Preheating Efficiency and Temperature Control

Cast iron pots offer excellent heat retention but require longer preheating times compared to carbon steel woks. Carbon steel woks heat up quickly and provide superior temperature control, making them ideal for precise deep-frying. Both materials maintain consistent heat, but carbon steel allows faster adjustment to prevent oil overheating.

Oil Capacity and Depth Considerations

Cast iron pots typically offer greater oil capacity and depth, making them ideal for deep-frying larger batches of food at consistent temperatures. Carbon steel woks, with their shallower depth, require less oil but may limit the quantity of food fried at once.

- Cast iron pot oil capacity - Usually accommodates 3 to 5 liters of oil, supporting deep, even frying.

- Carbon steel wok oil usage - Requires less oil due to its shallow shape, often around 1 to 2 liters.

- Depth considerations - Cast iron pots provide deeper frying space, reducing oil splatter and heat loss compared to carbon steel woks.

Safety and Handling During Deep-Frying

Cast iron pots are heavier and offer excellent heat retention, providing stable temperatures during deep-frying but require careful handling to avoid burns. Carbon steel woks heat up quickly and are lighter, making them easier to maneuver but demand constant attention to maintain safe oil temperatures.

- Heat Stability - Cast iron's superior heat retention reduces oil temperature fluctuations, enhancing frying safety.

- Weight Considerations - Carbon steel woks are lighter, minimizing strain when lifting hot oil.

- Surface Handling - Both materials develop seasoning that improves non-stick properties but require proper maintenance to avoid rust, which can be a safety concern.

Using appropriate heat-resistant gloves and stable cookware placement is crucial regardless of material choice to ensure safe deep-frying practices.

Flavor Development and Food Texture

Cast iron pots provide even heat retention, enhancing flavor development through consistent deep-frying temperatures that create a rich, crispy texture in foods. Carbon steel woks heat up faster and promote quicker moisture evaporation, resulting in a lighter, crisper exterior.

Cast iron's porous surface absorbs oil over time, subtly intensifying flavors with repeated use, which is ideal for dishes requiring deep, complex taste profiles. Carbon steel woks, being thinner, allow for better control of frying temperature, producing evenly textured food with a delicate crunch. Both materials influence the Maillard reaction differently, where cast iron supports deeper caramelization while carbon steel encourages a bright, crisp finish.

Cleaning and Maintenance Requirements

Cast iron pots require thorough drying and regular seasoning to prevent rust and maintain their non-stick surface, making cleaning more labor-intensive. Carbon steel woks also need seasoning but dry faster and are less prone to rust, simplifying maintenance after deep-frying. Both cookware types benefit from avoiding soap and abrasive scrubbers to preserve their seasoning and cooking performance.

Durability and Longevity

Cast iron pots offer exceptional durability due to their thick, sturdy construction, making them ideal for frequent deep-frying. Carbon steel woks, while durable, are lighter and require more maintenance to prevent rust and maintain their non-stick properties.

- Cast Iron Durability - Cast iron is highly resistant to warping and can last for decades with proper seasoning and care.

- Carbon Steel Longevity - Carbon steel woks develop a natural patina over time but need regular oiling to avoid corrosion.

- Maintenance Differences - Cast iron is more forgiving with maintenance, while carbon steel demands consistent upkeep to preserve its longevity.

Related Important Terms

Thermal mass retention

Cast iron pots excel in thermal mass retention due to their dense structure, maintaining consistent oil temperature during deep-frying, which ensures even cooking and a crispy texture. Carbon steel woks heat up rapidly but lose heat faster when food is added, requiring more frequent temperature adjustments for optimal frying results.

Oil pooling effect

Cast iron pots retain heat exceptionally well, creating a stable temperature ideal for deep-frying but can cause oil pooling due to their thick walls and uneven heat distribution. Carbon steel woks heat up quickly and allow for better oil circulation with minimal pooling, resulting in crispier fried foods and more efficient oil use.

Smoke point adaptation

Cast iron pots, known for their excellent heat retention, maintain stable temperatures ideal for deep-frying but have a lower smoke point around 400degF, which may limit the use of certain oils. Carbon steel woks heat up rapidly and reach higher temperatures with smoke points exceeding 450degF, making them better suited for oils like peanut or sunflower oil that require higher heat for optimal deep-frying performance.

Crust development kinetics

Cast iron pots exhibit superior heat retention and even distribution, promoting faster crust development kinetics during deep-frying due to their high thermal mass. Carbon steel woks heat rapidly but cool quickly, resulting in less consistent crust formation and slower kinetic rates compared to cast iron.

Seasoning matrix

Cast iron pots develop a thicker, more durable seasoning matrix ideal for consistent deep-frying heat retention and non-stick performance, whereas carbon steel woks form a thinner, more reactive seasoning layer that heats rapidly but may require more frequent re-seasoning to maintain optimal frying conditions. The superior seasoning stability of cast iron enhances oil bonding and flavor infusion, making it preferable for prolonged deep-frying sessions compared to the lightweight and agile carbon steel wok.

Drop temperature lag

Cast iron pots exhibit a slower temperature drop lag due to their higher heat capacity, maintaining steady oil temperature during deep-frying and reducing food soaking in oil. Carbon steel woks heat up and cool down more rapidly, requiring more frequent temperature adjustments to prevent oil temperature fluctuations and ensure consistent frying results.

Flavor reactivity footprint

Cast iron pots retain heat exceptionally well, providing a consistent frying temperature and imparting a robust, seasoned flavor to deep-fried foods through their reactive surface that enhances Maillard reactions. Carbon steel woks heat up quickly with a thinner profile, offering a more neutral flavor profile but less seasoning buildup, resulting in a lighter flavor reactivity footprint ideal for delicate ingredients.

Oil reuse cycles stability

Cast iron pots maintain consistent heat retention, enhancing oil stability through multiple deep-frying cycles, whereas carbon steel woks heat faster but may cause quicker oil degradation due to fluctuating temperatures. The dense structure of cast iron minimizes oil oxidation, supporting extended reuse cycles compared to the thinner carbon steel, which tends to accelerate oil breakdown.

Sear zone geometry

Cast iron pots provide a thicker sear zone ideal for steady, even heat retention during deep-frying, ensuring consistent oil temperature and optimal crust formation. Carbon steel woks feature a sloped sear zone that promotes rapid heat distribution but may require more frequent temperature adjustments to maintain ideal deep-frying conditions.

Cast iron pot vs carbon steel wok for deep-frying. Infographic

cookingdiff.com

cookingdiff.com