A thermometer provides precise internal temperature readings essential for ensuring pet food reaches safe cooking levels, preventing undercooking or overcooking. Infrared surface scanners measure the oil's surface temperature quickly but can be inaccurate for deep-frying as they don't capture temperature beneath the oil's surface. For deep-frying pet food, a thermometer remains the most reliable tool to monitor consistent heat and ensure food safety.

Table of Comparison

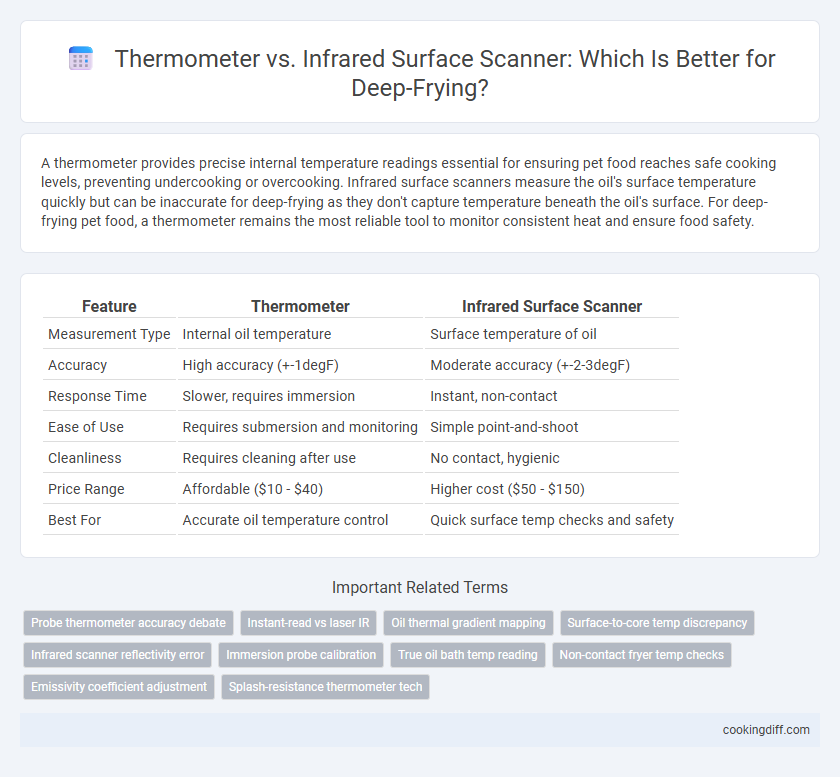

| Feature | Thermometer | Infrared Surface Scanner |

|---|---|---|

| Measurement Type | Internal oil temperature | Surface temperature of oil |

| Accuracy | High accuracy (+-1degF) | Moderate accuracy (+-2-3degF) |

| Response Time | Slower, requires immersion | Instant, non-contact |

| Ease of Use | Requires submersion and monitoring | Simple point-and-shoot |

| Cleanliness | Requires cleaning after use | No contact, hygienic |

| Price Range | Affordable ($10 - $40) | Higher cost ($50 - $150) |

| Best For | Accurate oil temperature control | Quick surface temp checks and safety |

Introduction: Importance of Accurate Temperature in Deep-Frying

| Accurate temperature measurement is critical in deep-frying to ensure food safety, optimal texture, and flavor. Traditional thermometers provide direct oil temperature readings by immersion, capturing the oil's internal heat, while infrared surface scanners measure only the oil's surface temperature, which can vary significantly from the actual frying temperature. Selecting the right tool affects cooking precision, oil longevity, and consistent results in professional and home frying environments. |

Overview: Thermometer and Infrared Surface Scanner Explained

A thermometer measures the internal temperature of the oil or food during deep-frying, providing accurate readings essential for optimal cooking. An infrared surface scanner detects the surface temperature of the oil without contact, allowing quick, non-invasive checks. Both tools offer critical temperature data but serve distinct purposes in monitoring deep-frying processes.

Precision: Which Tool Measures Oil Temperature Better?

Deep-frying precision relies heavily on accurate oil temperature measurement, critical for food safety and quality. Thermometers provide direct readings from the oil, while infrared surface scanners measure surface temperature, often leading to discrepancies.

- Thermometer Accuracy - Immersible thermometers measure internal oil temperature directly, ensuring precise control.

- Infrared Limitations - Infrared scanners only gauge surface temperature, which can fluctuate and misrepresent true oil heat.

- Consistency in Cooking - Thermometers maintain consistent frying temperatures, reducing undercooked or burnt food.

For optimal deep-frying results, thermometers offer superior precision over infrared surface scanners in measuring oil temperature.

Speed: Comparing Real-Time Readings

Thermometers provide direct and continuous real-time readings by measuring the oil's internal temperature, essential for maintaining precise deep-frying conditions. Infrared surface scanners offer rapid, non-contact temperature assessments but primarily gauge the oil's surface temperature, which may not reflect the actual cooking environment.

In deep-frying, thermometers ensure consistent heat levels by delivering accurate internal temperature data crucial for food safety and quality. Infrared scanners excel in speed, allowing quick surface checks without immersion, useful for a preliminary temperature overview but less reliable for detailed control. Choosing between the two depends on the need for accuracy versus speed in monitoring.

Ease of Use: User Experience and Practicality

Thermometers offer direct contact temperature readings, making them highly accurate but requiring food to be monitored more carefully during deep-frying. Infrared surface scanners provide quick, non-contact temperature assessments, enhancing convenience though sometimes sacrificing precision with oil temperature variations.

- Thermometer - Provides precise oil temperature measurements essential for consistent deep-frying results.

- Infrared Surface Scanner - Enables rapid temperature checks without dipping into the oil, improving safety and speed.

- User Experience - Thermometers require immersion and patience, while infrared scanners offer greater ease and practicality for busy kitchens.

Safety Considerations When Measuring Hot Oil

Using a thermometer for deep-frying ensures accurate measurement of the oil's internal temperature, reducing the risk of overheating and potential fires. Infrared surface scanners measure only the oil's surface temperature, which may not reflect the overall oil heat accurately, posing safety concerns.

Thermometers with heat-resistant probes minimize direct contact with hot oil, decreasing the chance of splashes and burns during temperature checks. Infrared scanners eliminate physical contact but require careful positioning to avoid false readings from steam or hot air reflections near the fryer.

Versatility: Applications Beyond Deep-Frying

Infrared surface scanners excel in quick, contactless temperature measurements suitable for various cooking tasks beyond deep-frying, such as grilling and baking. Thermometers, while primarily used for precise internal temperature readings, also serve diverse culinary and laboratory applications where accuracy is critical.

- Infrared Scanner Versatility - Enables rapid temperature assessment of surfaces in cooking, HVAC, and automotive diagnostics.

- Thermometer Accuracy - Provides precise internal temperature data vital for food safety and scientific experiments.

- Multi-Environment Use - Both tools adapt to industrial, medical, and food-processing environments for comprehensive temperature monitoring.

Maintenance and Durability of Each Device

Which device offers better maintenance and durability for deep-frying applications? Deep-fry thermometers typically require regular calibration and careful cleaning to maintain accuracy, but their durable metal probes withstand high temperatures over prolonged use. Infrared surface scanners have fewer moving parts and need less frequent calibration, though their sensors can be sensitive to grease buildup and may require more delicate handling to ensure long-term functionality.

Cost-Effectiveness: Investment vs Value

Thermometers for deep-frying offer precise internal oil temperature readings, ensuring food safety and optimal cooking results with a low upfront cost. Infrared surface scanners provide non-contact temperature measurements, ideal for quick checks but usually come at a higher price point with limited depth accuracy. Evaluating investment vs value, thermometers present a more cost-effective solution for consistent frying quality in both home and commercial kitchens.

Related Important Terms

Probe thermometer accuracy debate

Probe thermometers provide precise internal temperature readings by penetrating the food, ensuring accurate doneness critical for safe deep-frying. Infrared surface scanners measure only the oil's surface temperature, often leading to inconsistent and less reliable results compared to the direct contact accuracy of probe thermometers.

Instant-read vs laser IR

Instant-read thermometers provide precise internal temperature measurements of oil, ensuring accurate control for optimal deep-frying results, while laser infrared surface scanners offer quick, non-contact surface temperature readings but may not reflect the actual oil temperature consistently due to surface variations. Choosing between them depends on whether you prioritize immediate internal accuracy or rapid surface monitoring during the deep-frying process.

Oil thermal gradient mapping

Thermometers provide precise oil temperature readings at a specific point, crucial for monitoring thermal gradients during deep-frying, while infrared surface scanners deliver rapid, non-contact temperature mapping across the oil surface, identifying hotspots and uneven heating. Combining both tools enhances accuracy and ensures optimal oil thermal gradient management to achieve consistent frying quality and food safety.

Surface-to-core temp discrepancy

Thermometers provide accurate core temperature readings essential for ensuring food safety and doneness during deep-frying, while infrared surface scanners only measure the external temperature, often missing the crucial surface-to-core temperature discrepancy. This discrepancy can lead to undercooked interiors or overcooked exteriors, making thermometers more reliable for precise temperature control in deep-frying processes.

Infrared scanner reflectivity error

Infrared surface scanners for deep-frying often suffer from reflectivity errors caused by shiny or uneven surfaces, leading to inaccurate temperature readings compared to traditional thermometers. These errors affect the precision of oil temperature measurement, making thermometers more reliable for maintaining optimal frying conditions.

Immersion probe calibration

Immersion probe thermometers provide precise temperature calibration by directly measuring the oil's internal heat during deep-frying, ensuring accurate control of cooking conditions. Infrared surface scanners only measure the oil's surface temperature, which can lead to inconsistent calibration and less reliable frying results.

True oil bath temp reading

A probe thermometer provides an accurate measurement of the true oil bath temperature by immersing directly in the oil, ensuring precise control for optimal deep-frying results. Infrared surface scanners only measure the oil's surface temperature, which can lead to misleading readings and inconsistent frying outcomes due to temperature variations below the surface.

Non-contact fryer temp checks

Infrared surface scanners provide accurate, non-contact temperature measurements of deep-fryer surfaces, reducing contamination risks and enabling real-time heat monitoring without interrupting cooking. Thermometers require direct contact with oil, which can disturb frying conditions and pose safety hazards, making infrared scanners more efficient for continuous temperature checks.

Emissivity coefficient adjustment

For deep-frying, using a thermometer with emissivity coefficient adjustment ensures accurate internal oil temperature readings by compensating for the oil's specific emissivity properties, whereas infrared surface scanners require precise emissivity calibration to avoid inaccurate surface temperature measurements caused by reflective oil surfaces. Proper emissivity adjustment is crucial in both devices to achieve safe and consistent frying temperatures, preventing undercooking or oil degradation.

Thermometer vs infrared surface scanner for deep-frying. Infographic

cookingdiff.com

cookingdiff.com