Traditional thermometers provide direct contact measurement, ensuring precise temperature readings essential for deep-frying pet to achieve a crispy texture without overcooking. Infrared thermometers offer quick, non-contact readings that help monitor oil temperature efficiently but may be less accurate due to surface temperature variations. Choosing the right thermometer impacts cooking consistency and food safety when deep-frying pet.

Table of Comparison

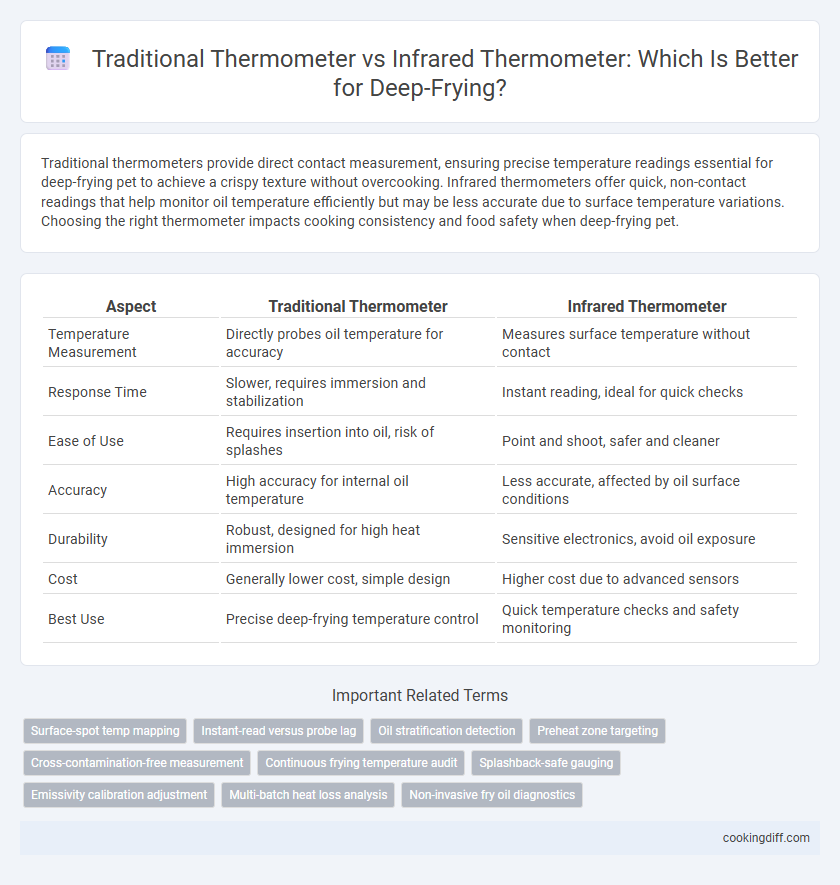

| Aspect | Traditional Thermometer | Infrared Thermometer |

|---|---|---|

| Temperature Measurement | Directly probes oil temperature for accuracy | Measures surface temperature without contact |

| Response Time | Slower, requires immersion and stabilization | Instant reading, ideal for quick checks |

| Ease of Use | Requires insertion into oil, risk of splashes | Point and shoot, safer and cleaner |

| Accuracy | High accuracy for internal oil temperature | Less accurate, affected by oil surface conditions |

| Durability | Robust, designed for high heat immersion | Sensitive electronics, avoid oil exposure |

| Cost | Generally lower cost, simple design | Higher cost due to advanced sensors |

| Best Use | Precise deep-frying temperature control | Quick temperature checks and safety monitoring |

Understanding Deep-Frying Temperature Control

Traditional thermometers provide direct contact temperature readings by immersing the probe into the oil, ensuring accurate measurement of the deep-frying oil temperature between 325degF and 375degF. Infrared thermometers measure surface temperature quickly without contact, but can be less accurate for oil since they only read surface temperature and may be affected by splattering or steam.

Precise temperature control is crucial for deep-frying to avoid undercooking or burning food, as fluctuations outside the ideal range affect texture and oil absorption. Using a traditional probe thermometer helps maintain consistent heat by measuring oil temperature inside the fryer, while infrared thermometers offer rapid checks for surface temperature but should be complemented with a probe for best results.

What is a Traditional Thermometer?

A traditional thermometer for deep-frying typically features a metal probe that is submerged directly into the oil to measure its temperature. It provides accurate readings by detecting the internal temperature of the oil, essential for consistent frying results.

- Metal Probe Sensor - The probe is inserted into the oil to gauge the actual oil temperature, ensuring precise heat measurement.

- Analog or Digital Display - The temperature reading is shown on a dial or digital screen, allowing easy monitoring during frying.

- Manual Monitoring - The thermometer requires close observation and adjustment to maintain optimal frying conditions.

Introduction to Infrared Thermometers

What are the key differences between traditional and infrared thermometers for deep-frying? Infrared thermometers measure surface temperature without direct contact, providing quick and hygienic readings ideal for hot oil. These devices use infrared sensors to detect thermal radiation, making them precise tools for maintaining optimal frying temperatures.

Accuracy: Traditional vs Infrared Thermometers

Traditional thermometers provide direct contact temperature readings, delivering highly accurate measurements essential for safe and consistent deep-frying. Infrared thermometers measure surface temperature without contact, which can result in less precise readings due to hot spots and oil movement.

- Contact Accuracy - Traditional thermometers measure the oil's internal temperature, ensuring accurate monitoring throughout the deep-frying process.

- Surface Measurement - Infrared thermometers only capture surface heat, making them prone to inaccuracies caused by oil turbulence or steam.

- Response Time - Traditional thermometers may take longer to stabilize but provide reliable data, whereas infrared thermometers offer instant but potentially fluctuating readings.

For consistent deep-frying results, traditional thermometers are generally preferred due to their superior accuracy and reliability.

Response Time Comparison

Traditional thermometers for deep-frying often have slower response times due to their need to be immersed in oil, potentially delaying accurate temperature readings. Infrared thermometers provide near-instantaneous surface temperature measurements, allowing for quicker adjustments during the frying process.

- Traditional thermometer response - Typically takes 15-30 seconds to stabilize and provide an accurate oil temperature reading.

- Infrared thermometer response - Delivers temperature readings within 1-2 seconds by detecting surface heat remotely.

- Practical impact - Faster response from infrared thermometers helps maintain optimal frying temperature, reducing overcooking or undercooking risks.

Safety and Ease-of-Use Considerations

| Thermometer Type | Safety Considerations | Ease-of-Use |

|---|---|---|

| Traditional Thermometer | Requires immersion in hot oil, increasing risk of burns and splashes during temperature checks. | Needs constant monitoring and manual handling, which can be cumbersome during active frying. |

| Infrared Thermometer | Measures temperature from a distance, reducing direct contact with hot oil and minimizing burn risks. | Provides instant readings without physical contact, enhancing convenience and speed during frying. |

Maintenance and Durability

Traditional thermometers require regular calibration and careful cleaning to maintain accuracy and prevent oil contamination during deep-frying. Infrared thermometers demand less maintenance as they are non-contact devices, reducing the risk of damage and contamination.

Durability-wise, traditional thermometers with glass components are prone to breakage from high heat or accidental drops, necessitating careful handling. Infrared thermometers, often encased in rugged plastic, resist heat and physical impact better, extending their lifespan in busy kitchen environments. Choosing infrared technology enhances reliability and lowers upkeep efforts in professional and home deep-frying settings.

Cost and Accessibility

Traditional thermometers for deep-frying are typically more affordable, with prices ranging from $5 to $20, making them accessible for home cooks and small businesses. These devices are widely available in supermarkets and kitchenware stores, ensuring easy purchase without the need for specialized outlets.

Infrared thermometers, while more expensive--usually between $30 and $100--offer contactless temperature measurement that can enhance safety during deep-frying. They may require online purchase or specialized retailers, which can limit immediate accessibility for some users.

Best Practices for Deep-Frying Temperature Monitoring

For accurate deep-frying temperature monitoring, traditional thermometers offer direct contact readings inside the oil, ensuring precise control over cooking conditions. Infrared thermometers provide quick surface temperature measurements but may not reflect the true internal oil temperature, leading to less consistent results. Best practices recommend using a high-quality, immersion-style traditional thermometer calibrated regularly to maintain optimal frying temperature and food quality.

Related Important Terms

Surface-spot temp mapping

Traditional thermometers provide accurate internal oil temperature readings crucial for maintaining deep-frying consistency, while infrared thermometers excel in surface-spot temperature mapping, allowing quick assessment of oil hotspots and temperature variations. Combining both tools optimizes cooking precision by ensuring uniform heat distribution and preventing oil degradation during deep frying.

Instant-read versus probe lag

Traditional thermometers with probes measure deep-frying oil temperature by direct immersion, causing lag due to heat transfer time, while infrared thermometers offer instant-read measurements by detecting surface temperature without contact. Infrared thermometers provide faster temperature readings but may not accurately reflect the internal oil temperature, making probe thermometers more reliable despite slower response times for precise deep-frying control.

Oil stratification detection

Traditional thermometers provide accurate internal oil temperature readings critical for maintaining frying temperature but may fail to detect oil stratification caused by density differences in used oil layers. Infrared thermometers offer surface temperature measurements enabling quicker identification of temperature inconsistencies on the oil surface, which can indicate early stages of oil stratification affecting frying quality.

Preheat zone targeting

Traditional thermometers provide direct oil temperature readings essential for accurate preheat zone targeting in deep-frying, ensuring consistent heat at the optimal 350degF to 375degF range. Infrared thermometers offer quick surface temperature measurements but may miss internal oil temperature variations critical for maintaining frying quality and safety.

Cross-contamination-free measurement

Infrared thermometers provide a cross-contamination-free measurement by detecting temperature without direct contact, making them ideal for deep-frying where food safety is critical. Traditional thermometers require insertion into the oil, increasing the risk of contaminating the cooking medium and compromising hygiene.

Continuous frying temperature audit

Traditional thermometers provide accurate, real-time temperature readings essential for maintaining consistent oil heat during continuous deep-frying, while infrared thermometers offer quick, non-contact surface temperature measurements but may lack precision in oil temperature monitoring. For continuous frying temperature audits, traditional thermometers ensure reliable thermal control, reducing the risk of undercooking or overheating oil.

Splashback-safe gauging

Traditional thermometers provide accurate temperature readings by direct immersion in oil, ensuring precise control during deep-frying but risking oil splashback and burns. Infrared thermometers measure surface temperature from a distance, offering splashback-safe gauging while potentially sacrificing accuracy inside the oil compared to probe thermometers.

Emissivity calibration adjustment

Traditional thermometers require immersion in oil for accurate temperature readings during deep-frying, but their emissivity calibration is inherent and fixed, making them reliable for direct contact measurements. Infrared thermometers demand precise emissivity adjustment to accurately measure oil surface temperature, as incorrect emissivity settings can lead to significant temperature reading errors in deep-frying applications.

Multi-batch heat loss analysis

Traditional thermometers provide continuous immersion readings, accurately tracking oil temperature fluctuations during multi-batch deep-frying and revealing cumulative heat loss over time. Infrared thermometers offer rapid surface temperature measurements but may miss internal oil temperature drops between batches, leading to less precise multi-batch heat loss analysis.

Traditional thermometer vs infrared thermometer for deep-frying. Infographic

cookingdiff.com

cookingdiff.com