Deep-frying uses hot oil at high temperatures, providing faster cooking times and better energy efficiency compared to cold-oil frying, which requires longer heating periods to achieve desired results. Cold-oil frying often leads to uneven cooking and increased energy consumption due to prolonged heat exposure. Optimizing oil temperature in deep-frying minimizes energy waste and enhances overall cooking performance.

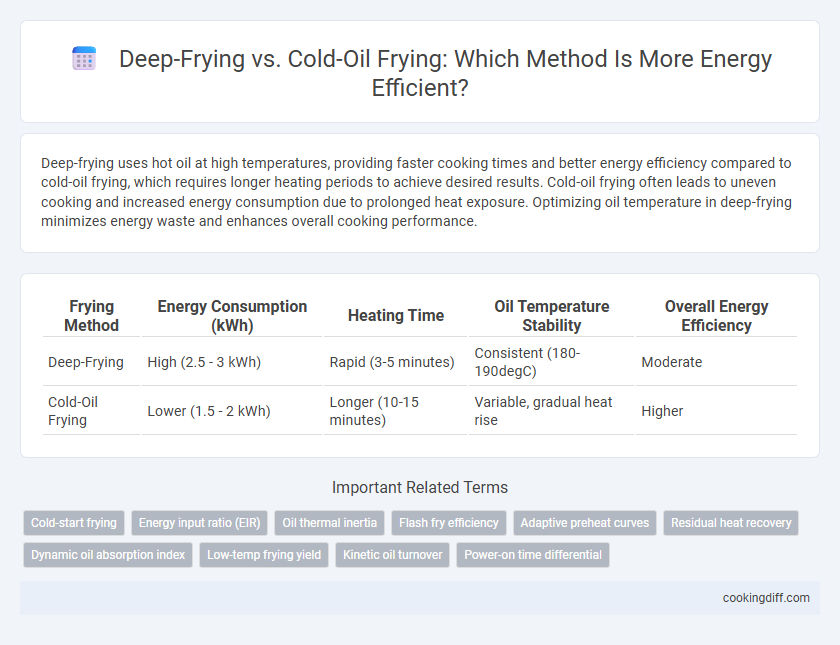

Table of Comparison

| Frying Method | Energy Consumption (kWh) | Heating Time | Oil Temperature Stability | Overall Energy Efficiency |

|---|---|---|---|---|

| Deep-Frying | High (2.5 - 3 kWh) | Rapid (3-5 minutes) | Consistent (180-190degC) | Moderate |

| Cold-Oil Frying | Lower (1.5 - 2 kWh) | Longer (10-15 minutes) | Variable, gradual heat rise | Higher |

Understanding Deep-Frying and Cold-Oil Frying

Deep-frying involves submerging food in hot oil at temperatures typically between 350degF and 375degF, resulting in rapid cooking and a crispy texture. Cold-oil frying uses oil heated gradually from room temperature, which can lead to longer cooking times and increased energy consumption.

- Energy Efficiency - Deep-frying is more energy-efficient due to faster heat transfer and shorter cooking durations.

- Oil Temperature Control - Precise temperature maintenance in deep-frying reduces oil absorption and improves food quality.

- Heat Distribution - Deep-frying provides consistent and uniform heat distribution compared to cold-oil frying.

Energy Consumption in Traditional Deep-Frying

Traditional deep-frying consumes significantly more energy due to the continuous heating of large oil volumes at high temperatures around 175-190degC. Maintaining this temperature requires sustained energy input, often resulting in higher electricity or gas consumption compared to cold-oil frying methods.

Energy efficiency is reduced by heat loss from oil exposure and the need for prolonged cooking times to properly cook food. By contrast, cold-oil frying uses less oil volume and heats slower, leading to lower overall energy consumption during the cooking process.

How Cold-Oil Frying Works

Cold-oil frying involves immersing food in oil heated gradually from room temperature to frying temperature, reducing initial energy spikes typical of deep-frying. This method allows the oil to heat more evenly, conserving energy by minimizing heat loss during preheating.

Deep-frying rapidly heats oil to high temperatures, often requiring more energy to maintain optimal cooking heat. Cold-oil frying, therefore, optimizes thermal energy use by gently increasing oil temperature, improving overall energy efficiency in frying processes.

Comparing Heating Times and Energy Usage

Deep-frying heats oil to high temperatures rapidly, significantly reducing cooking time compared to cold-oil frying, which requires gradual heating. This efficient heat transfer results in lower overall energy consumption during the cooking process.

- Rapid heating in deep-frying - Oil reaches optimal cooking temperatures faster, minimizing energy use.

- Cold-oil frying's gradual heating - Prolonged heating time increases energy consumption due to slower temperature rise.

- Energy efficiency comparison - Deep-frying uses less energy per minute of cooking because of quicker heat penetration and retention.

Choosing deep-frying over cold-oil frying can lead to significant energy savings in domestic and commercial kitchens.

Oil Temperature Control and Efficiency

How does oil temperature control impact energy efficiency in deep-frying compared to cold-oil frying? Maintaining an optimal oil temperature of around 350degF (175degC) in deep-frying ensures rapid cooking and reduces energy consumption by minimizing heat loss. Cold-oil frying requires longer cooking times and frequent reheating, leading to higher overall energy usage.

Food Quality: Texture, Taste, and Oil Absorption

Deep-frying preserves food texture by rapidly forming a crispy outer layer, minimizing oil absorption and enhancing taste complexity. Cold-oil frying, while energy-efficient, often leads to greasier texture and diminished flavor development due to prolonged cooking time.

- Texture Enhancement - Deep-frying creates a superior crispiness that cold-oil frying fails to achieve, resulting in improved sensory appeal.

- Taste Development - High-temperature deep-frying induces Maillard reactions that deepen flavor profiles compared to the cooler temperatures of cold-oil frying.

- Oil Absorption - Rapid sealing of food surfaces during deep-frying reduces oil uptake, whereas cold-oil frying allows more oil to penetrate, affecting health and quality.

Safety Considerations: Deep-Frying vs Cold-Oil Frying

Deep-frying involves heating oil to high temperatures, increasing the risk of burns and oil fires if not monitored carefully. Cold-oil frying, which uses lower temperatures, reduces the chance of splattering and thermal injuries but may require longer cooking times that impact energy use. Safety equipment like thermostats and proper ventilation are essential in both methods to prevent accidents and ensure energy-efficient cooking.

Impact on Kitchen Environment and Ventilation

| Deep-Frying | Generates high levels of smoke, vapors, and odors requiring robust kitchen ventilation systems with grease filters to maintain air quality and reduce fire hazards. |

| Cold-Oil Frying | Produces fewer emissions and less heat, resulting in reduced ventilation demand and lower energy consumption for air extraction and filtration systems. |

| Energy Efficiency Impact | Deep-frying increases ventilation energy costs due to elevated thermal load and particulate matter, whereas cold-oil frying supports a cleaner environment and minimizes HVAC strain. |

Cost Analysis: Oil and Energy Expenses

Deep-frying requires maintaining high oil temperatures, which leads to higher energy consumption compared to cold-oil frying methods that operate at lower temperatures. The cost of oil degradation in deep-frying necessitates more frequent oil replacement, increasing overall expenses. Cold-oil frying reduces both energy use and oil replenishment costs, offering a more cost-efficient cooking process.

Related Important Terms

Cold-start frying

Cold-start frying consumes less total energy by heating oil gradually from room temperature, reducing initial heat loss compared to preheated deep-frying. This method enhances fuel efficiency by minimizing the temperature overshoot and maintaining more stable oil temperatures during cooking.

Energy input ratio (EIR)

Deep-frying demonstrates a higher Energy Input Ratio (EIR) compared to cold-oil frying, indicating greater energy efficiency by maximizing heat transfer to the food. Cold-oil frying typically shows a lower EIR due to slower heat conduction and longer cooking times, resulting in increased overall energy consumption.

Oil thermal inertia

Deep-frying features high oil thermal inertia, maintaining consistent temperatures and reducing energy spikes compared to cold-oil frying, which requires prolonged heating to reach optimal cooking temperature. This efficiency in thermal retention minimizes overall energy consumption by stabilizing heat transfer during deep-frying processes.

Flash fry efficiency

Flash frying during deep-frying maximizes energy efficiency by rapidly reaching and maintaining optimal oil temperatures between 175degC and 190degC, minimizing heat loss and cooking time compared to cold-oil frying. Cold-oil frying requires prolonged heating, resulting in higher energy consumption and less precise temperature control, reducing overall frying efficiency.

Adaptive preheat curves

Adaptive preheat curves in deep-frying optimize energy consumption by precisely controlling oil temperature, reducing heat loss compared to cold-oil frying methods that rely on gradual heating. This dynamic temperature management enhances energy efficiency and shortens cooking times, minimizing fuel usage while maintaining food quality.

Residual heat recovery

Deep-frying demonstrates superior energy efficiency compared to cold-oil frying by effectively utilizing residual heat recovery, which minimizes energy waste and maintains optimal oil temperature longer. This process reduces energy consumption up to 30% by capturing and reusing heat from the cooking vessel, enhancing overall thermal management in commercial kitchens.

Dynamic oil absorption index

Deep-frying exhibits a lower Dynamic Oil Absorption Index compared to cold-oil frying, indicating more efficient oil utilization and reduced energy consumption during cooking. This enhanced efficiency results from the consistent high temperature that minimizes oil uptake and shortens frying time, optimizing both energy use and food quality.

Low-temp frying yield

Deep-frying at optimal temperatures ensures higher cooking efficiency, minimizing oil absorption and preserving texture, whereas cold-oil frying often results in longer cooking times and increased energy consumption due to gradual temperature rise. Studies reveal that low-temperature frying yields lower energy efficiency and suboptimal food quality compared to consistent high-temperature deep-frying methods.

Kinetic oil turnover

Deep-frying demonstrates higher energy efficiency than cold-oil frying due to its significantly greater kinetic oil turnover, which facilitates rapid heat transfer and consistent cooking temperatures. Enhanced kinetic oil turnover in deep-frying minimizes energy loss by maintaining optimal thermal conditions, resulting in reduced cooking times and lower overall energy consumption.

Deep-frying vs cold-oil frying for energy efficiency. Infographic

cookingdiff.com

cookingdiff.com