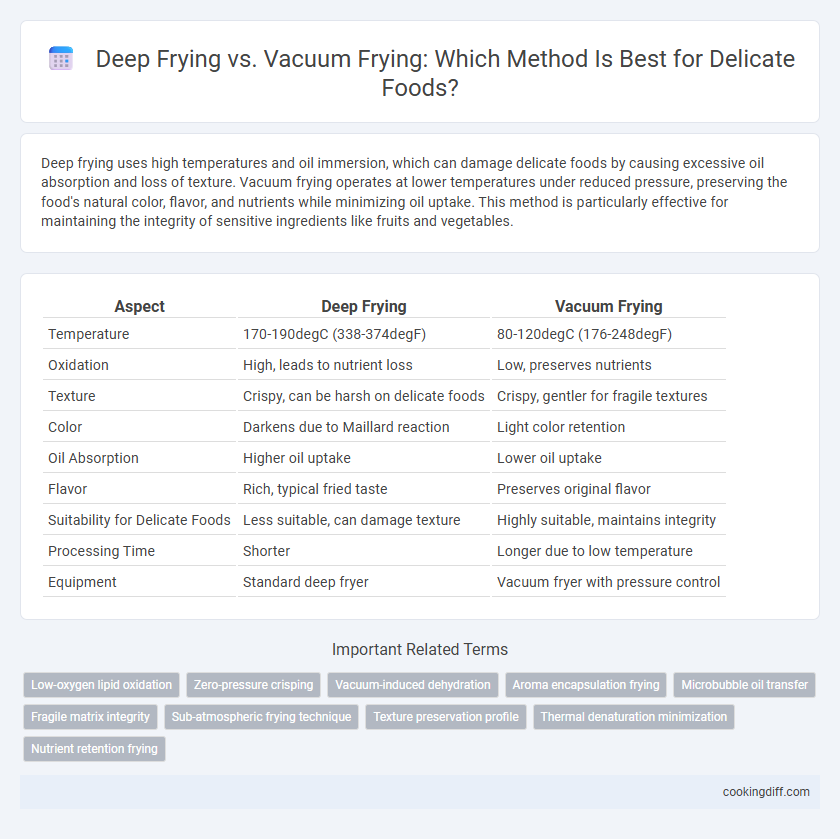

Deep frying uses high temperatures and oil immersion, which can damage delicate foods by causing excessive oil absorption and loss of texture. Vacuum frying operates at lower temperatures under reduced pressure, preserving the food's natural color, flavor, and nutrients while minimizing oil uptake. This method is particularly effective for maintaining the integrity of sensitive ingredients like fruits and vegetables.

Table of Comparison

| Aspect | Deep Frying | Vacuum Frying |

|---|---|---|

| Temperature | 170-190degC (338-374degF) | 80-120degC (176-248degF) |

| Oxidation | High, leads to nutrient loss | Low, preserves nutrients |

| Texture | Crispy, can be harsh on delicate foods | Crispy, gentler for fragile textures |

| Color | Darkens due to Maillard reaction | Light color retention |

| Oil Absorption | Higher oil uptake | Lower oil uptake |

| Flavor | Rich, typical fried taste | Preserves original flavor |

| Suitability for Delicate Foods | Less suitable, can damage texture | Highly suitable, maintains integrity |

| Processing Time | Shorter | Longer due to low temperature |

| Equipment | Standard deep fryer | Vacuum fryer with pressure control |

Introduction to Deep Frying and Vacuum Frying

Deep frying involves submerging food in hot oil, typically between 160degC and 190degC, to create a crispy texture while cooking quickly. This method is ideal for foods that can withstand high temperatures without losing structural integrity.

Vacuum frying occurs under reduced pressure, allowing frying at lower temperatures around 90degC to 120degC, preserving delicate food textures and nutrients. It minimizes oxidation and oil absorption, making it suitable for fragile items like fruits and thin slices of vegetables.

How Deep Frying Works: Traditional Method Explained

How does traditional deep frying work for delicate foods? Traditional deep frying involves submerging food in hot oil at temperatures typically between 350degF and 375degF, creating a crispy exterior while cooking the interior quickly. This method can cause delicate foods to absorb excess oil and potentially become soggy or damaged due to high heat and turbulence.

Vacuum Frying: Modern Technique Overview

Vacuum frying uses reduced pressure to fry delicate foods at lower temperatures, preserving texture and nutrients better than traditional deep-frying. This modern technique minimizes oxidation and color degradation, making it ideal for fragile fruits and vegetables.

- Lower frying temperature - Vacuum frying operates at 80-120degC, significantly cooler than deep-frying's 160-190degC, reducing thermal damage.

- Nutrient retention - The absence of oxygen during vacuum frying helps maintain vitamins, antioxidants, and natural flavors.

- Enhanced product quality - Vacuum frying produces crisp, less greasy snacks with vibrant colors and improved shelf life.

Temperature Control: Key Differences in Frying Methods

Deep frying typically operates at higher temperatures around 170-190degC, which can cause delicate foods to degrade or absorb excessive oil. Vacuum frying, conducted under reduced pressure at lower temperatures between 90-120degC, preserves texture and nutritional quality by minimizing thermal damage.

Temperature control in vacuum frying is crucial for maintaining the integrity of sensitive ingredients, preventing oxidation and moisture loss. In contrast, deep frying's higher heat accelerates cooking but risks overheating and over-crisping delicate food items. Precise temperature regulation in vacuum frying enhances product quality and extends shelf life compared to conventional deep frying.

Oil Absorption: Impact on Delicate Foods

Deep frying typically results in higher oil absorption due to intense heat and direct contact with oil, which can compromise the texture and flavor of delicate foods. Vacuum frying operates under low pressure and lower temperatures, significantly reducing oil uptake while preserving the structural integrity and natural taste of sensitive ingredients. Studies show vacuum frying decreases oil absorption by up to 50%, making it ideal for maintaining quality in products like fruits and thin slices of vegetables.

Preservation of Flavor and Color

| Deep-frying uses high temperatures (typically 160-190degC) that can cause delicate foods to lose natural flavor and result in browning or color degradation due to Maillard reactions. |

| Vacuum frying operates at lower temperatures (around 80-120degC) under reduced pressure, which better preserves the original flavor compounds and vibrant colors of delicate foods by minimizing oxidation and thermal damage. |

| Studies show vacuum frying reduces oil absorption and maintains sensory qualities, making it superior for retaining the freshness and appeal of delicate fruits and vegetables compared to traditional deep-frying. |

Nutritional Quality Retention

Deep frying subjects delicate foods to high temperatures that can degrade sensitive nutrients like vitamins and antioxidants, resulting in lower nutritional quality retention. In contrast, vacuum frying operates at reduced pressure and lower temperatures, preserving heat-sensitive nutrients more effectively and enhancing the retention of natural flavors and colors.

Vacuum frying also minimizes the formation of harmful compounds such as acrylamide, which can occur during high-temperature deep frying. This method maintains higher levels of essential nutrients while producing crisp textures, making it a superior choice for nutrient preservation in delicate food products.

Texture and Crispness Comparison

Deep frying preserves a distinct crispness and firm texture in delicate foods due to high-temperature oil immersion. Vacuum frying, operating under lower pressure, minimizes oxidation while producing a lighter, more tender crispness that maintains the food's natural colors and flavors.

- Deep frying crispness - Creates a crunchy exterior through rapid moisture evaporation at temperatures typically above 170degC (338degF).

- Vacuum frying tenderness - Uses reduced pressure and lower temperatures around 90-120degC (194-248degF) to prevent structural damage and preserve delicate textures.

- Oxidation impact - Vacuum frying limits oil oxidation and nutrient loss, enhancing overall crispness quality compared to traditional deep frying.

Cost and Equipment Considerations

Deep frying is generally more cost-effective due to lower initial equipment expenses and simpler maintenance requirements compared to vacuum frying. Vacuum frying demands specialized, costly machinery designed to operate under reduced pressure, increasing overall production costs.

- Equipment Cost - Deep frying equipment is widely available and less expensive than vacuum fryers.

- Operating Expenses - Vacuum frying typically incurs higher energy costs because of vacuum pumps and temperature controls.

- Maintenance - Deep fryers require standard cleaning, whereas vacuum fryers need specialized maintenance to sustain vacuum integrity.

Choosing between deep frying and vacuum frying involves balancing cost efficiency with the preservation of delicate food quality.

Related Important Terms

Low-oxygen lipid oxidation

Vacuum frying significantly reduces low-oxygen lipid oxidation compared to traditional deep-frying by operating under reduced oxygen conditions, preserving the delicate textures and flavors of sensitive foods. This method minimizes the formation of harmful oxidation products, extending shelf life while maintaining nutritional quality in fragile food items.

Zero-pressure crisping

Vacuum frying preserves delicate foods by reducing frying temperature and pressure, preventing oxidation and moisture loss, which results in zero-pressure crisping without structural damage. This method maintains natural colors, flavors, and nutrients better than traditional deep-frying, producing a lighter, crispier texture ideal for fragile ingredients.

Vacuum-induced dehydration

Vacuum frying employs vacuum-induced dehydration to gently remove moisture from delicate foods at lower temperatures, preserving texture, color, and nutritional value better than traditional deep-frying. This method minimizes oxidation and thermal damage, resulting in crispier, less oily products ideal for sensitive ingredients like fruits and vegetables.

Aroma encapsulation frying

Vacuum frying preserves the delicate aroma of foods by reducing oxidation and moisture loss through low-pressure cooking, enhancing flavor retention compared to traditional deep-frying. This method encapsulates volatile compounds more effectively, resulting in crisp textures and intensified aromas ideal for fragile ingredients like fruits and herbs.

Microbubble oil transfer

Microbubble oil transfer in deep-frying enhances heat penetration but risks damaging delicate foods due to high shear forces and oxidation; vacuum frying significantly reduces microbubble turbulence by operating under low pressure, preserving texture and nutrient integrity. This method minimizes oil absorption and oxidation, making vacuum frying superior for maintaining the quality of sensitive ingredients like fruits and vegetables.

Fragile matrix integrity

Deep frying exposes delicate foods to high temperatures and oxygen, often causing cell structure breakdown and loss of fragile matrix integrity, resulting in texture degradation. Vacuum frying operates at lower temperatures and reduced oxygen levels, preserving the cellular matrix and maintaining the structural quality of fragile foods more effectively.

Sub-atmospheric frying technique

Vacuum frying utilizes sub-atmospheric pressure to lower the boiling point of oil, preserving the texture, color, and nutritional content of delicate foods better than traditional deep-frying. This technique reduces oil absorption and minimizes oxidation, resulting in healthier, crispier products with enhanced flavor stability.

Texture preservation profile

Vacuum frying preserves the delicate texture of foods by reducing oil absorption and preventing oxidation through low-pressure, low-temperature cooking, maintaining crispness and natural flavor better than traditional deep-frying. Deep-frying exposes foods to higher temperatures and atmospheric pressure, often causing increased oil uptake and textural degradation, making it less suitable for delicate products requiring gentle handling.

Thermal denaturation minimization

Vacuum frying significantly reduces thermal denaturation in delicate foods by operating at lower temperatures and reduced oxygen levels, preserving texture and nutritional value better than traditional deep-frying. This controlled environment minimizes oxidative damage and protein breakdown, ensuring higher quality and sensory attributes in sensitive food products.

Deep frying vs vacuum frying for delicate foods. Infographic

cookingdiff.com

cookingdiff.com