A steel pot offers reliable heat retention and traditional deep-frying control, making it ideal for consistent oil temperature management. An induction fryer heats rapidly with precise temperature settings, enhancing energy efficiency and safety. Selecting between them depends on user preference for manual control versus modern convenience in deep-frying pets safely.

Table of Comparison

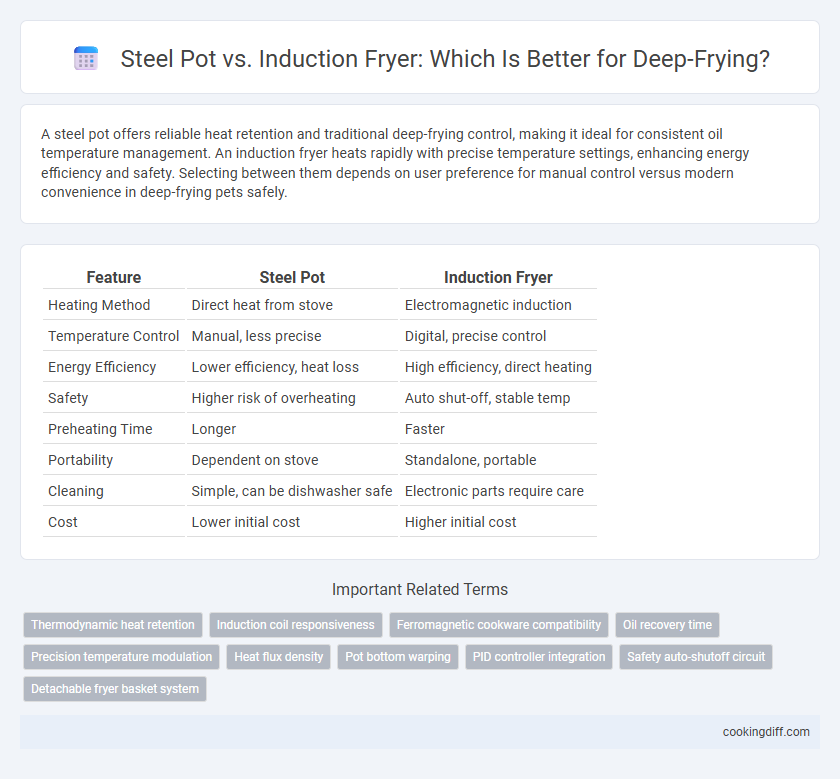

| Feature | Steel Pot | Induction Fryer |

|---|---|---|

| Heating Method | Direct heat from stove | Electromagnetic induction |

| Temperature Control | Manual, less precise | Digital, precise control |

| Energy Efficiency | Lower efficiency, heat loss | High efficiency, direct heating |

| Safety | Higher risk of overheating | Auto shut-off, stable temp |

| Preheating Time | Longer | Faster |

| Portability | Dependent on stove | Standalone, portable |

| Cleaning | Simple, can be dishwasher safe | Electronic parts require care |

| Cost | Lower initial cost | Higher initial cost |

Introduction: Choosing the Right Deep-Frying Equipment

Choosing the right deep-frying equipment significantly impacts cooking efficiency and food quality. Steel pots, valued for their durability and heat retention, provide consistent frying temperatures essential for crispy results.

Induction fryers offer precise temperature control and faster heating through electromagnetic energy, enhancing energy efficiency. Selecting between steel pots and induction fryers depends on cooking volume, temperature management preferences, and energy considerations.

Overview: Steel Pot vs Induction Fryer

Steel pots provide traditional deep-frying with excellent heat retention and durability, ensuring even cooking results. Induction fryers utilize electromagnetic technology for rapid, precise temperature control, enhancing safety and energy efficiency during frying.

Steel pots are favored for their versatility and ability to maintain consistent heat over prolonged periods, ideal for recipes that require steady frying temperatures. Induction fryers offer fast heating and cooling, reducing cooking time and preventing oil degradation. Both options support high-temperature cooking, but induction fryers require compatible cookware, while steel pots work independently on any heat source.

Heating Efficiency Comparison

Induction fryers offer superior heating efficiency compared to traditional steel pots by directly heating the cooking vessel through electromagnetic fields. Steel pots rely on external heat sources which often leads to slower, uneven heating and increased energy consumption.

- Induction heating - transfers energy directly to the pot, reducing heat loss and improving energy efficiency.

- Steel pot conduction - requires heat to pass through the metal, causing slower temperature response and hotspots.

- Energy consumption - induction fryers use less power by rapidly achieving and maintaining precise temperatures.

Induction fryers provide faster heat-up times and more consistent frying temperatures, optimizing cooking efficiency and food quality.

Temperature Control and Stability

Steel pots provide excellent heat retention and even temperature distribution, essential for maintaining stable frying temperatures during deep-frying. Induction fryers offer precise temperature control through digital settings and instant adjustments, reducing the risk of oil overheating or cooling down. For consistent and reliable deep-frying results, induction fryers typically outperform steel pots in temperature stability and control efficiency.

Oil Usage and Safety Features

| Equipment | Oil Usage | Safety Features |

|---|---|---|

| Steel Pot | Requires larger volume of oil to maintain deep-frying temperature due to high heat capacity and lack of insulation. | Open design increases risk of spills and burns; often lacks built-in temperature control, raising the chance of overheating oil. |

| Induction Fryer | Optimizes oil usage with precise temperature control and insulated cooking chamber, reducing oil degradation and waste. | Equipped with automatic shut-off, temperature sensors, and secure lids to minimize fire hazards and hot oil splatter. |

Cooking Consistency and Food Quality

Steel pots provide even heat distribution, ensuring consistent cooking temperatures that prevent hot spots and uneven frying, crucial for achieving a crispy, golden exterior. Induction fryers offer precise temperature control, which maintains steady heat levels and reduces oil degradation, resulting in better food quality and less oil absorption. Both methods support superior cooking consistency, but induction fryers enhance efficiency and safety while preserving the food's texture and flavor.

Ease of Use and Maintenance

Steel pots offer simplicity with straightforward cleaning and durability, making them easy to maintain after deep-frying sessions. Induction fryers provide precise temperature control and faster heating but require careful handling and specific cookware compatibility.

- Steel pot ease of use - Requires manual heating and monitoring for consistent temperature control.

- Steel pot maintenance - Durable material resists corrosion and is dishwasher safe for easy cleaning.

- Induction fryer maintenance - Needs regular coil cleaning and limited to induction-compatible pots to prevent damage.

Energy Consumption and Cost Analysis

Steel pots require direct heat sources and often consume more energy due to uneven heat distribution, leading to longer cooking times in deep-frying. Induction fryers use electromagnetic fields to heat the cooking vessel quickly and efficiently, reducing overall energy consumption by up to 30% compared to traditional steel pots.

The initial cost of steel pots is generally lower, but the ongoing energy costs and potential for uneven frying can raise total expenses. Induction fryers have higher upfront costs but lower operating expenses and improved temperature control, resulting in cost savings over time, especially for frequent deep-frying tasks.

Space and Kitchen Compatibility

Steel pots offer versatility and can fit various stovetops but often require more space due to their bulkier design. Induction fryers are compact and designed specifically for deep-frying, making them ideal for kitchens with limited counter space.

- Space Efficiency - Induction fryers have a smaller footprint compared to traditional steel pots, saving valuable kitchen space.

- Kitchen Compatibility - Steel pots work on most heat sources, while induction fryers require compatible induction cooktops.

- Storage Convenience - The compact and often stackable design of induction fryers enhances kitchen organization and storage.

Related Important Terms

Thermodynamic heat retention

Steel pots offer superior thermodynamic heat retention for deep-frying due to their thicker walls and higher thermal mass, maintaining consistent oil temperature during cooking. Induction fryers provide rapid, precise temperature control but may experience quicker heat fluctuations because of thinner materials and direct heating elements.

Induction coil responsiveness

Induction fryers provide superior temperature control and rapid heat adjustments through responsive induction coil technology, ensuring consistent oil temperature during deep-frying. Steel pots require external heat sources with slower responsiveness, leading to less efficient heat distribution and potential temperature fluctuations affecting frying quality.

Ferromagnetic cookware compatibility

Steel pots made from ferromagnetic materials ensure full compatibility with induction fryers, enabling efficient heat transfer essential for deep-frying. In contrast, cookware lacking ferromagnetic properties, such as some stainless steel variants or aluminum pots, will not function properly on induction fryers, impacting cooking performance.

Oil recovery time

Steel pots retain heat well, leading to faster oil recovery time after food is added, which helps maintain consistent frying temperature and reduces oil absorption. Induction fryers offer precise temperature control but often experience slower oil recovery due to smaller oil volumes and rapid heat fluctuations.

Precision temperature modulation

Steel pots provide consistent heat retention but lack precise temperature control, often causing fluctuations during deep-frying. Induction fryers utilize electromagnetic technology to offer accurate temperature modulation, ensuring optimal frying conditions and improved food quality.

Heat flux density

Steel pots offer high heat flux density due to their excellent thermal conductivity and thick walls, enabling rapid temperature recovery during deep-frying. Induction fryers provide precise and consistent heat flux control with minimal heat loss, optimizing energy efficiency and maintaining stable frying temperatures.

Pot bottom warping

Steel pots with thicker, high-quality bottoms are less prone to warping during deep-frying compared to cheaper models, ensuring consistent heat distribution and food quality. Induction fryers typically feature sturdy, warp-resistant bases designed to maintain flatness for optimal electromagnetic energy transfer and precise temperature control.

PID controller integration

Steel pots paired with PID controllers offer precise temperature regulation essential for deep-frying, minimizing oil degradation and enhancing food quality. Induction fryers inherently include PID control systems that rapidly adjust heating elements for consistent temperature maintenance, improving energy efficiency and frying performance.

Safety auto-shutoff circuit

Steel pots lack built-in safety features, increasing the risk of overheating during deep-frying, whereas induction fryers commonly include an auto-shutoff circuit that effectively prevents accidents by cutting power when temperatures exceed safe limits. This integrated safety mechanism in induction fryers enhances control and reduces hazards, making them a safer option for deep-frying compared to traditional steel pots.

Steel pot vs induction fryer for deep-frying. Infographic

cookingdiff.com

cookingdiff.com