Steel pots offer superior heat retention and even distribution, making them ideal for consistent deep-frying temperatures that produce crispy results. Ceramic-coated pots provide a non-stick surface that simplifies cleanup and reduces the risk of food sticking, though they may not conduct heat as evenly as steel. Choosing between steel and ceramic-coated pots depends on the importance of thermal performance versus ease of maintenance in deep-frying.

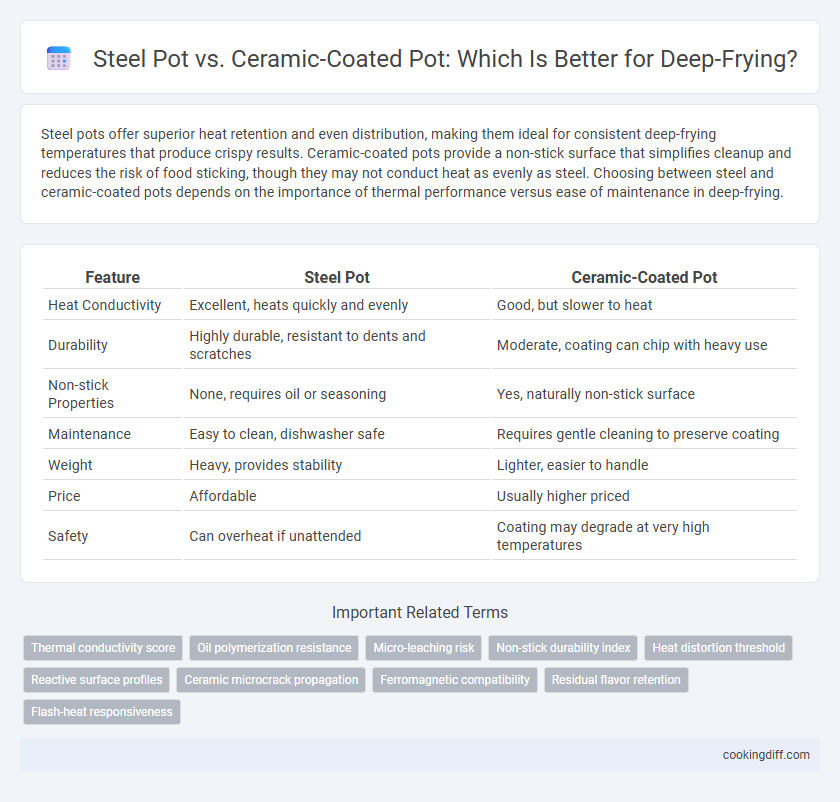

Table of Comparison

| Feature | Steel Pot | Ceramic-Coated Pot |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Good, but slower to heat |

| Durability | Highly durable, resistant to dents and scratches | Moderate, coating can chip with heavy use |

| Non-stick Properties | None, requires oil or seasoning | Yes, naturally non-stick surface |

| Maintenance | Easy to clean, dishwasher safe | Requires gentle cleaning to preserve coating |

| Weight | Heavy, provides stability | Lighter, easier to handle |

| Price | Affordable | Usually higher priced |

| Safety | Can overheat if unattended | Coating may degrade at very high temperatures |

Introduction: Steel vs Ceramic-Coated Pots for Deep-Frying

Which pot material performs better for deep-frying: steel or ceramic-coated? Steel pots offer superior heat conduction and durability, making them ideal for maintaining consistent frying temperatures. Ceramic-coated pots provide a non-stick surface that simplifies cleanup but may not retain heat as efficiently during extended frying sessions.

Heat Distribution: Comparing Steel and Ceramic-Coated Pots

Steel pots offer excellent heat conductivity, allowing for quick and even heat distribution essential for consistent deep-frying results. Ceramic-coated pots provide a more gradual and uniform heat spread, reducing the risk of hot spots and burning during cooking. The choice between steel and ceramic-coated pots significantly impacts temperature control and the overall quality of the fried food.

Temperature Control and Retention in Deep-Frying

Steel pots offer superior heat conductivity and rapid temperature adjustments, essential for maintaining consistent frying conditions. Ceramic-coated pots provide excellent heat retention, ensuring stable temperatures but respond slower to temperature changes. Choosing between these depends on whether precise temperature control or consistent heat retention is prioritized during deep-frying.

Oil Absorption and Sticking Issues

Steel pots conduct heat efficiently, minimizing oil absorption during deep-frying by maintaining a consistent temperature that prevents food from soaking up excess oil. Their smooth surface reduces sticking issues, allowing fried foods to release easily without tearing or residue.

Ceramic-coated pots offer a non-stick surface that significantly lowers the chance of food sticking, enhancing the frying experience while reducing oil usage. However, the coating can be more prone to damage over time, which may increase sticking and oil absorption if the ceramic layer deteriorates.

Safety and Durability During Deep-Frying

Steel pots offer superior durability and resistance to high temperatures, making them safer for prolonged deep-frying sessions. Ceramic-coated pots provide non-stick benefits but may lose coating integrity over time, affecting safety and lifespan.

- Heat Tolerance - Steel pots withstand higher temperatures without warping or degrading during deep-frying.

- Non-Toxic Surface - Ceramic coatings can release harmful substances if scratched or overheated.

- Longevity - Steel pots maintain structural integrity for years, while ceramic coatings may chip or wear down.

Choosing a steel pot enhances safety and durability for consistent deep-frying performance.

Cleaning and Maintenance Considerations

| Steel Pot | Steel pots are highly durable and resistant to scratches, making them easier to clean after deep-frying. They typically withstand aggressive scrubbing and high temperatures without damage, reducing long-term maintenance. However, steel pots may require seasoning to prevent rust, ensuring optimal longevity and performance. |

| Ceramic-Coated Pot | Ceramic-coated pots feature a non-stick surface that simplifies post-frying cleaning by preventing food residue buildup. The coating is sensitive to metal utensils and harsh cleaning agents, necessitating gentle washing and careful handling to avoid chipping. Long-term maintenance involves avoiding abrasive sponges and following manufacturer guidelines to preserve the coating's integrity. |

Flavor Impact on Fried Foods

Steel pots conduct heat efficiently, promoting even cooking and consistent browning that enhances the crispy texture of deep-fried foods. Their high heat retention helps develop rich, caramelized flavors without imparting any metallic taste.

Ceramic-coated pots offer non-reactive surfaces that prevent food from absorbing unwanted flavors, preserving the natural taste of fried ingredients. However, their lower heat conductivity may result in less uniform frying, potentially affecting the final flavor and texture.

Lifespan and Wear Under High Heat

Steel pots exhibit superior durability and maintain structural integrity under the extreme temperatures required for deep-frying. Ceramic-coated pots, while resistant to sticking, often suffer from coating degradation and chipping when exposed to repeated high heat over time.

- Steel pot lifespan - Steel pots can last several years with minimal wear when used properly for deep-frying.

- Ceramic coating wear - Ceramic coatings tend to wear down or crack after frequent exposure to temperatures above 400degF (204degC).

- Heat resistance - Steel offers consistent heat retention without the risk of surface damage, making it more reliable for extended deep-frying sessions.

Cost Comparison: Steel vs Ceramic-Coated Pots

Steel pots are generally more affordable than ceramic-coated pots, making them a budget-friendly option for deep-frying. Ceramic-coated pots tend to have a higher upfront cost but may offer longer-term value due to their non-stick properties and durability.

- Initial Investment - Steel pots typically cost less, averaging around $20 to $50 based on size and brand.

- Durability and Maintenance - Ceramic-coated pots can cost $40 to $100 but resist sticking and are easier to clean, potentially extending usability.

- Long-Term Value - While steel pots are cheaper initially, the frequent replacement due to rust or wear may increase overall expenses compared to ceramic-coated options.

Related Important Terms

Thermal conductivity score

Steel pots exhibit higher thermal conductivity scores compared to ceramic-coated pots, enabling faster and more even heat distribution during deep-frying. Ceramic-coated pots, while offering non-stick benefits, typically have lower thermal conductivity, which can result in slower heating and less consistent frying temperatures.

Oil polymerization resistance

Steel pots exhibit superior oil polymerization resistance compared to ceramic-coated pots, maintaining stable cooking temperatures and preventing oil breakdown during prolonged deep-frying. This durability enhances oil longevity and food quality by minimizing harmful residue buildup and preserving optimal frying conditions.

Micro-leaching risk

Steel pots offer superior durability and resistance to micro-leaching compared to ceramic-coated pots, which may degrade or release small amounts of coating materials when exposed to high temperatures during deep-frying. Choosing a high-grade stainless steel pot minimizes the risk of harmful contaminants entering food, ensuring safer cooking and prolonged pot lifespan.

Non-stick durability index

Steel pots typically offer a non-stick durability index rating between 7 and 9 due to their resistance to scratches and high heat tolerance, making them a reliable choice for deep-frying. Ceramic-coated pots, while initially providing a slick non-stick surface with an index of 8 to 10, tend to degrade faster under repeated high-temperature frying, reducing their long-term non-stick effectiveness to a 5 or 6 on the durability scale.

Heat distortion threshold

Steel pots offer a higher heat distortion threshold than ceramic-coated pots, making them better suited for deep-frying at consistently high temperatures without warping. Ceramic-coated pots may suffer heat distortion and coating degradation when exposed to intense heat, reducing their durability and cooking performance over time.

Reactive surface profiles

Steel pots exhibit a reactive surface that can impart metallic flavors and discolor oils during deep-frying, whereas ceramic-coated pots offer a non-reactive, smooth surface that maintains oil purity and prevents flavor contamination. The ceramic coating's inert properties also enhance heat distribution efficiency, reducing hotspots and promoting consistent frying results compared to the uneven thermal conductivity of bare steel surfaces.

Ceramic microcrack propagation

Ceramic-coated pots for deep-frying are prone to ceramic microcrack propagation, which can compromise the pot's durability and release harmful substances into the oil. In contrast, steel pots offer higher resistance to thermal shock and mechanical stress, ensuring safer and longer-lasting performance during high-temperature frying.

Ferromagnetic compatibility

Steel pots, especially those made from stainless steel or carbon steel, exhibit excellent ferromagnetic compatibility, making them ideal for induction cooktops used in deep-frying. Ceramic-coated pots often lack ferromagnetic properties, limiting their use on induction surfaces and potentially affecting heat distribution during the deep-frying process.

Residual flavor retention

Steel pots exhibit minimal residual flavor retention due to their non-porous, durable surface, making them ideal for deep-frying a variety of foods without flavor transfer. Ceramic-coated pots, while offering non-stick properties, tend to absorb and retain flavors over time, potentially impacting the taste of subsequent fried dishes.

Steel pot vs ceramic-coated pot for deep-frying. Infographic

cookingdiff.com

cookingdiff.com