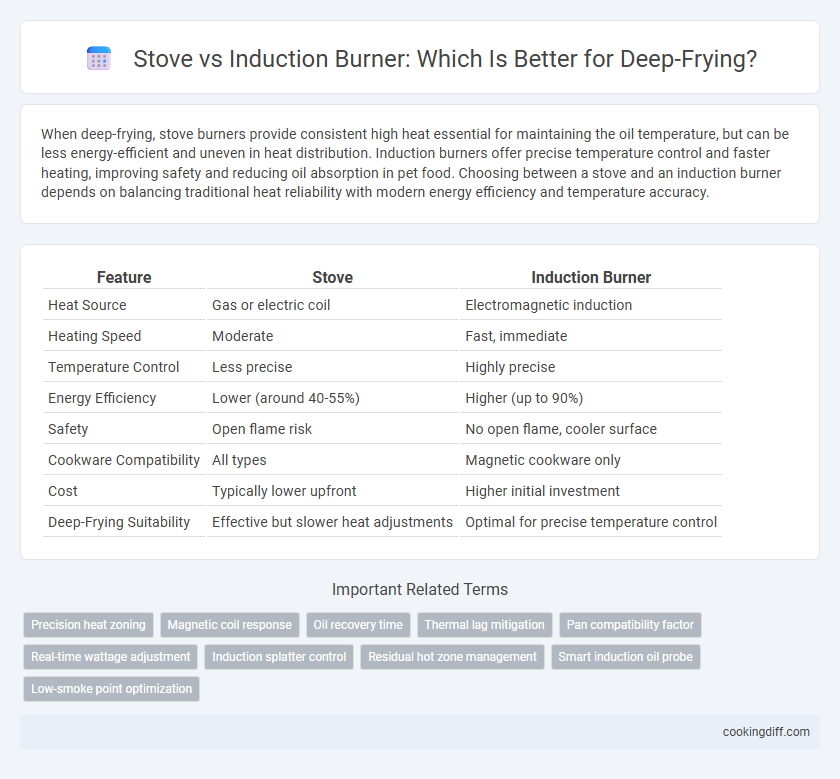

When deep-frying, stove burners provide consistent high heat essential for maintaining the oil temperature, but can be less energy-efficient and uneven in heat distribution. Induction burners offer precise temperature control and faster heating, improving safety and reducing oil absorption in pet food. Choosing between a stove and an induction burner depends on balancing traditional heat reliability with modern energy efficiency and temperature accuracy.

Table of Comparison

| Feature | Stove | Induction Burner |

|---|---|---|

| Heat Source | Gas or electric coil | Electromagnetic induction |

| Heating Speed | Moderate | Fast, immediate |

| Temperature Control | Less precise | Highly precise |

| Energy Efficiency | Lower (around 40-55%) | Higher (up to 90%) |

| Safety | Open flame risk | No open flame, cooler surface |

| Cookware Compatibility | All types | Magnetic cookware only |

| Cost | Typically lower upfront | Higher initial investment |

| Deep-Frying Suitability | Effective but slower heat adjustments | Optimal for precise temperature control |

Introduction: Deep-Frying at Home

Deep-frying at home requires precise temperature control to ensure crispy, evenly cooked results. Traditional stoves offer direct heat but often suffer from inconsistent temperature regulation during deep-frying. Induction burners provide rapid, accurate heat adjustments, making them ideal for maintaining the optimal oil temperature needed for safe and efficient deep-frying.

Heat Control: Stove vs Induction Burner

Stove burners provide variable heat control but often suffer from uneven temperature distribution, which can affect deep-frying precision. Induction burners use electromagnetic fields to deliver consistent, rapid, and precise heat adjustments, optimizing frying results.

Induction burners offer superior temperature accuracy with fluctuations typically within +-1degC, enabling better control over oil temperature critical for deep-frying. Gas stoves can lag in responsiveness, causing oil to overheat or cool unevenly, leading to inconsistent cooking. The energy efficiency of induction technology also reduces heat loss, ensuring stable frying conditions and improved safety.

Temperature Precision for Frying

Induction burners offer superior temperature precision compared to traditional stoves, allowing for more consistent deep-frying results. This precise control reduces the risk of overheating and burning oil, ensuring food cooks evenly and retains optimal texture.

- Rapid temperature adjustment - Induction burners respond instantly to changes in heat settings, maintaining stable frying temperatures.

- Consistent heat distribution - The magnetic heating method delivers even heat directly to the pan, eliminating hot spots common with gas or electric stoves.

- Energy efficiency - Induction burners use less energy by heating only the cookware, leading to quicker reach of frying temperatures.

Choosing an induction burner improves frying precision, enhancing safety and food quality in deep-frying applications.

Safety Considerations When Deep-Frying

Which option provides safer temperature control for deep-frying: stove or induction burner? Induction burners offer precise temperature regulation, reducing the risk of overheating oil and potential fire hazards. Stoves may have slower response times and uneven heat distribution, increasing the chance of dangerous oil splatters during deep-frying.

Energy Efficiency in Deep-Frying

Induction burners deliver superior energy efficiency for deep-frying by directly heating the cookware through electromagnetic induction, reducing heat loss compared to traditional stoves. This results in faster heating times and lower electricity consumption during the frying process.

Conventional gas stoves lose a significant amount of energy as heat dissipates into the surrounding air, making them less efficient for sustained high-temperature cooking like deep-frying. Induction technology optimizes energy use, ensuring consistent oil temperature and improved frying performance.

Recovery Time: Oil Temperature Stability

Induction burners offer faster recovery time compared to traditional stoves, maintaining more stable oil temperatures during deep-frying. The precise temperature control of induction burners minimizes fluctuations, ensuring consistent cooking results and reducing oil degradation. In contrast, gas stoves often experience slower temperature recovery, leading to uneven frying and longer cooking times.

Convenience and User Experience

Stoves offer direct heat control and can accommodate larger, heavy-duty pots ideal for deep-frying, providing a traditional cooking experience. Induction burners heat cookware quickly and evenly, enhancing safety with precise temperature adjustments and cool-to-touch surfaces.

Users often find induction burners more convenient due to faster heat-up times and energy efficiency, reducing overall cooking time during deep-frying. However, stove setups may be preferred for their compatibility with a wider range of frying vessels and robust heat capacity.

Equipment Compatibility and Frying Vessel Choices

Stoves provide broad compatibility with various frying vessels including cast iron, stainless steel, and aluminum pans, making them versatile for deep-frying. Induction burners require magnetic-bottom vessels such as cast iron or stainless steel to efficiently heat oil for frying.

- Stove Compatibility - Accepts any pan material, allowing use of traditional deep-frying pots and woks.

- Induction Requirements - Requires induction-compatible cookware with ferrous metal bases to activate the heating element.

- Frying Efficiency - Induction burners offer rapid temperature control, enhancing oil temperature stability during deep-frying.

Cleaning and Maintenance

| Stove | Traditional stoves often have greasy surfaces and crevices that trap oil splatters, requiring frequent scrubbing and degreasing. Regular cleaning involves disassembling burner grates and drip pans, which can accumulate burnt residues. Maintenance includes ensuring burner functionality and addressing clogged gas ports for consistent flame control. |

| Induction Burner | Induction burners feature smooth, flat surfaces made of glass or ceramic, facilitating quick wipe-downs to remove oil splatters during and after deep-frying. Their sealed design prevents food and grease buildup inside the unit, reducing maintenance needs. Routine upkeep mainly involves using non-abrasive cleaners to preserve the surface and ensuring ventilation vents remain unobstructed. |

Related Important Terms

Precision heat zoning

Induction burners provide superior precision heat zoning compared to traditional stoves, allowing for consistent oil temperature control essential for deep-frying. This precise heat management reduces oil degradation and ensures evenly cooked, crispy results.

Magnetic coil response

Induction burners use magnetic coil response to generate heat directly in the cookware, offering faster temperature control and improved energy efficiency for deep-frying compared to traditional stoves. This magnetic induction heats the oil evenly and maintains consistent frying temperatures, reducing oil degradation and enhancing food quality.

Oil recovery time

Induction burners offer faster oil recovery time during deep-frying due to precise and consistent temperature control, maintaining optimal frying heat with minimal fluctuations. Traditional stoves typically have slower oil recovery, leading to longer waits for the oil to return to the desired temperature and potentially resulting in less efficient frying and increased oil absorption.

Thermal lag mitigation

Induction burners provide rapid heat adjustments and precise temperature control, significantly reducing thermal lag compared to traditional stoves during deep-frying. This efficiency ensures consistent oil temperature, minimizing undercooking or burning while enhancing energy savings.

Pan compatibility factor

Induction burners require pans made of ferromagnetic materials such as cast iron or magnetic stainless steel for effective deep-frying heat conduction, while traditional stoves are compatible with a wider variety of pan materials including aluminum and copper. Selecting the right pan ensures optimal temperature control and energy efficiency in deep-frying processes on either cooking surface.

Real-time wattage adjustment

Induction burners offer precise real-time wattage adjustment, ensuring consistent oil temperature during deep-frying, which enhances cooking control and reduces the risk of overheating. In contrast, traditional stoves typically lack this immediate power modulation, leading to temperature fluctuations that can affect food quality and safety.

Induction splatter control

Induction burners offer superior splatter control during deep-frying by providing precise temperature regulation and rapid heat adjustments, reducing oil overheating and minimizing splatter. Unlike traditional stoves, induction technology heats the pan directly, resulting in less oil agitation and a cleaner cooking environment.

Residual hot zone management

Induction burners offer superior residual hot zone management during deep-frying by rapidly cooling the cooking surface once the pot is removed, reducing the risk of overheating and oil degradation. In contrast, stoves maintain high residual heat for longer periods, increasing the chance of burning oil and creating safety hazards.

Smart induction oil probe

Smart induction oil probes on induction burners provide precise temperature control crucial for deep-frying, reducing the risk of overheating and improving oil longevity compared to traditional stoves. These probes quickly detect oil temperature fluctuations, ensuring consistent frying results and enhanced energy efficiency.

Stove vs induction burner for deep-frying. Infographic

cookingdiff.com

cookingdiff.com