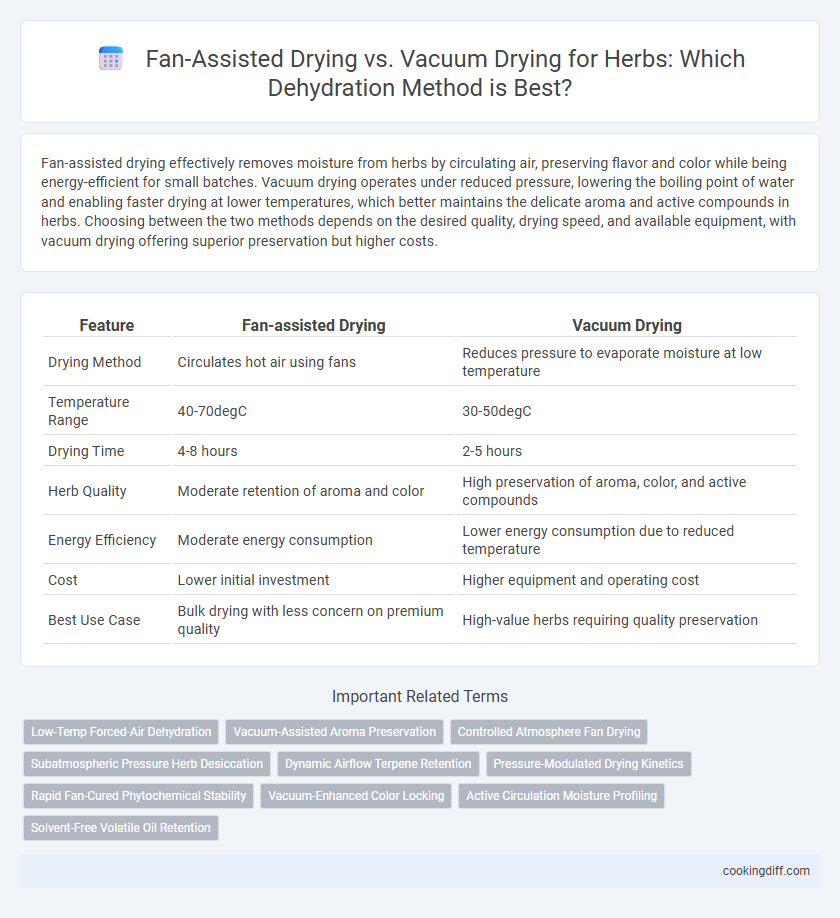

Fan-assisted drying effectively removes moisture from herbs by circulating air, preserving flavor and color while being energy-efficient for small batches. Vacuum drying operates under reduced pressure, lowering the boiling point of water and enabling faster drying at lower temperatures, which better maintains the delicate aroma and active compounds in herbs. Choosing between the two methods depends on the desired quality, drying speed, and available equipment, with vacuum drying offering superior preservation but higher costs.

Table of Comparison

| Feature | Fan-assisted Drying | Vacuum Drying |

|---|---|---|

| Drying Method | Circulates hot air using fans | Reduces pressure to evaporate moisture at low temperature |

| Temperature Range | 40-70degC | 30-50degC |

| Drying Time | 4-8 hours | 2-5 hours |

| Herb Quality | Moderate retention of aroma and color | High preservation of aroma, color, and active compounds |

| Energy Efficiency | Moderate energy consumption | Lower energy consumption due to reduced temperature |

| Cost | Lower initial investment | Higher equipment and operating cost |

| Best Use Case | Bulk drying with less concern on premium quality | High-value herbs requiring quality preservation |

Introduction to Drying Methods for Herbs

Fan-assisted drying uses airflow to remove moisture from herbs, accelerating the drying process through convection. Vacuum drying extracts water at lower temperatures by reducing atmospheric pressure, preserving herb quality and aroma.

- Fan-assisted drying enhances airflow - This method promotes faster moisture evaporation by circulating air around the herbs.

- Vacuum drying operates under low pressure - It reduces boiling points, allowing drying at gentle temperatures that protect sensitive compounds.

- Both methods optimize drying efficiency - Each technique balances speed, energy consumption, and herb quality retention differently.

What is Fan-Assisted Drying?

Fan-assisted drying uses a mechanical fan to circulate air around herbs, speeding up moisture evaporation and preventing mold growth. This method maintains a consistent temperature and airflow, which helps preserve the herbs' color, aroma, and essential oils.

The continuous movement of air in fan-assisted drying creates an even drying environment, reducing the risk of uneven drying or spoilage. It is a cost-effective technique suitable for home gardeners and small-scale herb producers seeking efficient dehydration.

Understanding Vacuum Drying Technology

How does vacuum drying technology improve the dehydration of herbs compared to fan-assisted drying? Vacuum drying reduces the boiling point of water by lowering pressure, allowing herbs to dry at lower temperatures and preserving their essential oils and nutrients. This method minimizes oxidation and enhances flavor retention, making it ideal for delicate herbs that are sensitive to heat.

Key Differences: Fan-Assisted vs Vacuum Drying

Fan-assisted drying uses continuous airflow at ambient pressure to remove moisture from herbs, which preserves essential oils but can lead to longer drying times and potential oxidation. Vacuum drying operates under reduced pressure, lowering the boiling point of water and enabling faster drying at lower temperatures, thereby better retaining color and flavor compounds. The main difference lies in the drying environment and temperature control, with vacuum drying offering superior quality retention for sensitive herbs compared to fan-assisted methods.

Efficiency and Speed of Herb Dehydration

Fan-assisted drying accelerates herb dehydration by enhancing air circulation, making the process energy-efficient and suitable for larger quantities. Vacuum drying, however, reduces drying time further by lowering the boiling point of water, preserving herb quality with less heat damage.

Fan-assisted drying is cost-effective and ideal for users prioritizing simplicity and moderate speed, while vacuum drying is optimized for high-quality preservation and rapid dehydration. Vacuum drying operates under reduced pressure, which prevents moisture oxidation and maintains flavor and color for premium herbs. Choosing between methods depends on balancing energy consumption, speed requirements, and herb quality retention for optimal dehydration results.

Impact on Herb Flavor and Nutrient Retention

| Fan-assisted drying preserves herb flavor moderately, but exposure to oxygen and heat can degrade sensitive nutrients such as vitamin C and essential oils. |

| Vacuum drying minimizes oxidation and operates at lower temperatures, resulting in superior retention of volatile compounds and antioxidants, thus maintaining stronger herb flavor and nutritional quality. |

Texture and Color Preservation

Fan-assisted drying uses circulating air to remove moisture from herbs, which helps maintain a natural texture but can sometimes lead to slight color fading due to prolonged exposure to oxygen. Vacuum drying operates under reduced pressure, enabling faster moisture removal at lower temperatures, preserving the vibrant green color and delicate texture of herbs more effectively. For optimal texture and color preservation in herb drying, vacuum drying is generally preferred despite higher equipment costs.

Energy Consumption and Cost Comparison

Fan-assisted drying for herbs typically consumes more energy due to continuous air circulation, while vacuum drying operates at lower temperatures, reducing overall energy use. Cost analysis shows that fan-assisted drying has lower initial equipment expenses but higher operational costs compared to vacuum drying.

- Energy Efficiency - Vacuum drying uses up to 40% less energy than traditional fan-assisted methods by utilizing low-pressure environments.

- Operational Cost - Fan-assisted drying incurs higher ongoing electricity costs due to prolonged drying times and fan operation.

- Equipment Investment - Vacuum drying systems require higher upfront capital investments but offer savings through reduced energy consumption.

Choosing the right drying method depends on balancing initial costs with long-term energy savings for herb processing.

Practical Considerations for Home Cooks

Fan-assisted drying is more accessible and cost-effective for home cooks, providing consistent airflow to speed up the drying process without special equipment. Vacuum drying preserves essential oils and aroma but requires specialized, expensive machines less common in home kitchens.

- Cost - Fan-assisted drying uses affordable equipment like household fans, while vacuum drying demands costly vacuum chambers and pumps.

- Ease of Use - Fan-assisted methods are simple and require minimal setup, whereas vacuum drying involves technical operation and maintenance.

- Quality Preservation - Vacuum drying better retains flavor and nutrients in herbs compared to fan-assisted drying, which may cause some degradation due to oxygen exposure.

Related Important Terms

Low-Temp Forced-Air Dehydration

Low-temp forced-air dehydration in fan-assisted drying preserves the delicate essential oils and vibrant colors of herbs by maintaining temperatures typically between 95degF and 125degF, ensuring optimal flavor retention. Compared to vacuum drying, which removes moisture under reduced pressure but may subject herbs to higher localized heat, fan-assisted drying offers a more energy-efficient and cost-effective method for consistent moisture removal without compromising herb quality.

Vacuum-Assisted Aroma Preservation

Vacuum drying maintains the delicate essential oils in herbs by reducing oxidation and evaporation, preserving their aroma better than fan-assisted drying. This method operates under low pressure and temperature conditions, ensuring higher retention of volatile compounds essential for flavor and therapeutic properties.

Controlled Atmosphere Fan Drying

Controlled atmosphere fan drying uses regulated air temperature, humidity, and flow to maintain herb quality and preserve essential oils during fan-assisted drying, making it more efficient than vacuum drying for delicate herbs. This method ensures consistent moisture removal while minimizing oxidation and color degradation compared to vacuum drying's low-pressure, low-temperature environment.

Subatmospheric Pressure Herb Desiccation

Fan-assisted drying relies on ambient air circulation to remove moisture from herbs, whereas vacuum drying utilizes subatmospheric pressure to significantly lower the boiling point of water, enabling faster dehydration at lower temperatures and preserving volatile oils and bioactive compounds. Subatmospheric pressure herb desiccation enhances drying efficiency while maintaining the sensory qualities and medicinal properties critical for high-quality herb processing.

Dynamic Airflow Terpene Retention

Fan-assisted drying enhances dynamic airflow, promoting faster moisture removal while preserving volatile terpenes in herbs through consistent air circulation. Vacuum drying reduces oxygen exposure and lowers drying temperatures, which helps retain delicate terpene profiles but may limit airflow dynamics compared to fan-assisted methods.

Pressure-Modulated Drying Kinetics

Fan-assisted drying accelerates herb dehydration by enhancing convective heat and mass transfer, maintaining atmospheric pressure that preserves essential oils but may result in longer drying times. Vacuum drying lowers pressure to reduce the boiling point of water, enabling faster moisture removal at lower temperatures, which better retains flavor compounds and bioactive constituents, optimizing pressure-modulated drying kinetics for superior herb quality.

Rapid Fan-Cured Phytochemical Stability

Fan-assisted drying accelerates moisture removal in herbs, maintaining rapid fan-cured phytochemical stability by preserving essential oils and antioxidants through controlled airflow and moderate temperatures. Vacuum drying enhances this stability further by reducing drying time under low pressure, minimizing thermal degradation of sensitive phytochemicals and optimizing herb quality.

Vacuum-Enhanced Color Locking

Vacuum drying preserves the vibrant green and natural hues of herbs by reducing oxidation and moisture loss, enhancing color retention compared to fan-assisted drying methods. The low-pressure environment in vacuum drying minimizes thermal degradation, ensuring herbs maintain their sensory and nutritional quality during dehydration.

Active Circulation Moisture Profiling

Fan-assisted drying leverages active circulation moisture profiling by continuously moving air across herbs, enhancing evaporation rates and ensuring uniform moisture removal. Vacuum drying operates under reduced pressure, accelerating drying at lower temperatures but relies less on active air circulation, which may result in varying moisture gradients within herb batches.

Fan-assisted Drying vs Vacuum Drying for herbs. Infographic

cookingdiff.com

cookingdiff.com