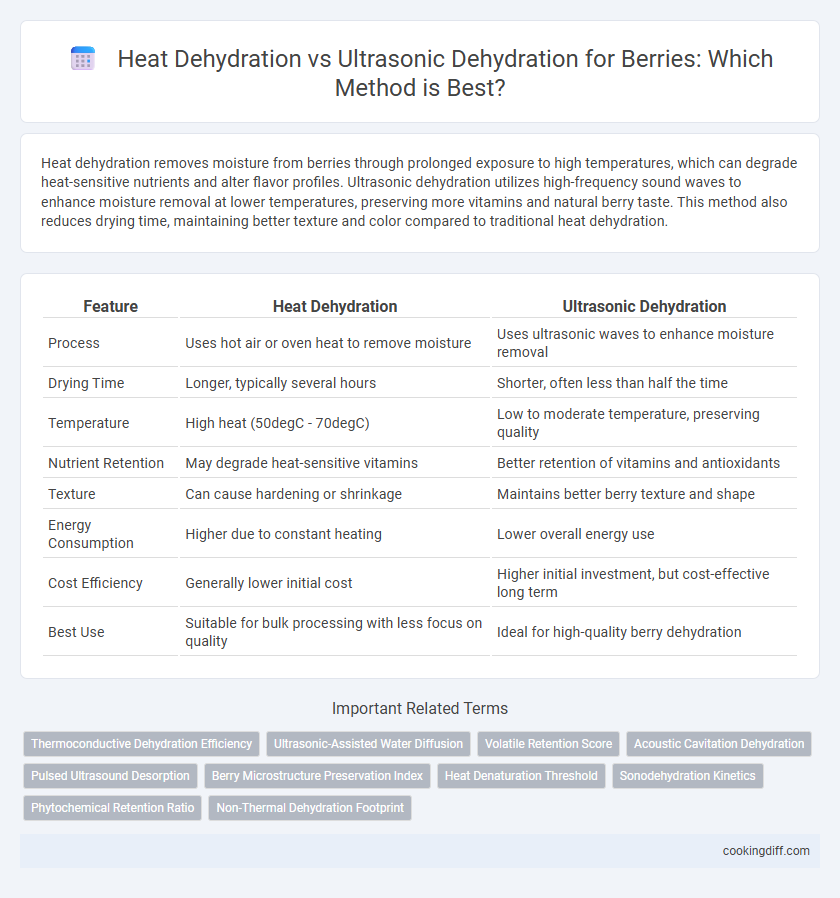

Heat dehydration removes moisture from berries through prolonged exposure to high temperatures, which can degrade heat-sensitive nutrients and alter flavor profiles. Ultrasonic dehydration utilizes high-frequency sound waves to enhance moisture removal at lower temperatures, preserving more vitamins and natural berry taste. This method also reduces drying time, maintaining better texture and color compared to traditional heat dehydration.

Table of Comparison

| Feature | Heat Dehydration | Ultrasonic Dehydration |

|---|---|---|

| Process | Uses hot air or oven heat to remove moisture | Uses ultrasonic waves to enhance moisture removal |

| Drying Time | Longer, typically several hours | Shorter, often less than half the time |

| Temperature | High heat (50degC - 70degC) | Low to moderate temperature, preserving quality |

| Nutrient Retention | May degrade heat-sensitive vitamins | Better retention of vitamins and antioxidants |

| Texture | Can cause hardening or shrinkage | Maintains better berry texture and shape |

| Energy Consumption | Higher due to constant heating | Lower overall energy use |

| Cost Efficiency | Generally lower initial cost | Higher initial investment, but cost-effective long term |

| Best Use | Suitable for bulk processing with less focus on quality | Ideal for high-quality berry dehydration |

Introduction to Berry Dehydration Methods

Berry dehydration involves removing moisture to extend shelf life and preserve nutritional quality. Heat dehydration and ultrasonic dehydration are two common techniques with distinct effects on berry texture and nutrient retention.

- Heat Dehydration - Utilizes controlled hot air or infrared heat to evaporate water, often resulting in longer drying times and potential nutrient loss.

- Ultrasonic Dehydration - Employs high-frequency sound waves to enhance moisture removal, reducing drying time and better preserving antioxidants and vitamins.

- Quality Impact - Ultrasonic methods typically maintain superior texture and color compared to heat dehydration, which can cause shrinkage and color degradation in berries.

Principles of Heat Dehydration

Heat dehydration for berries relies on applying controlled thermal energy to evaporate moisture, preserving the fruit's texture and flavor. This method typically uses hot air circulation, where temperatures range between 50degC to 70degC to avoid heat damage while effectively reducing water content.

Heat dehydration promotes enzymatic inactivation that preserves berry color and nutrient profiles during drying. Extended drying times at moderate temperatures enhance uniform moisture removal, preventing microbial growth and spoilage in the final product.

Understanding Ultrasonic Dehydration Technology

Ultrasonic dehydration technology uses high-frequency sound waves to remove moisture from berries, preserving their texture and nutritional value better than traditional heat dehydration methods. This technique enhances water evaporation by creating micro-vibrations that break apart water molecules without applying excessive heat.

Heat dehydration relies on elevated temperatures to evaporate moisture, which can degrade antioxidants and vitamins in berries. Ultrasonic dehydration minimizes thermal damage, maintaining higher levels of anthocyanins and flavor compounds. The technology also reduces drying time and energy consumption, offering an efficient alternative for preserving berry quality.

Comparative Efficiency: Heat vs Ultrasonic Dehydration

Which method offers superior efficiency for dehydrating berries: heat dehydration or ultrasonic dehydration? Heat dehydration typically requires longer drying times and may cause nutrient loss, whereas ultrasonic dehydration accelerates moisture removal while preserving berry quality. Ultrasonic techniques provide enhanced drying rates and better retention of antioxidants compared to conventional heat methods.

Impact on Berry Flavor and Nutritional Value

Heat dehydration often leads to significant loss of volatile compounds, resulting in diminished berry flavor and reduced levels of heat-sensitive nutrients such as vitamin C. Ultrasonic dehydration preserves more natural flavor profiles by minimizing thermal damage and maintaining higher antioxidant content. Studies show ultrasonic methods retain up to 30% more phenolic compounds compared to conventional heat drying techniques.

Texture and Appearance Differences in Dried Berries

Heat dehydration often leads to firmer, more shrunken dried berries with darker coloration due to longer exposure to elevated temperatures. Ultrasonic dehydration preserves a more vibrant appearance and softer texture by using sound waves to gently remove moisture without high heat.

- Texture Firmness - Heat dehydration creates a denser, chewier berry texture compared to the tender consistency retained by ultrasonic methods.

- Color Retention - Ultrasonic dehydration maintains brighter berry colors by minimizing thermal degradation of pigments.

- Shape Integrity - Berries dried ultrasonically tend to retain their original shape better, while heat dehydration causes more shrinkage and deformation.

Energy Consumption and Environmental Considerations

| Heat dehydration of berries typically consumes higher energy due to prolonged heating periods at temperatures between 50-70degC, resulting in greater CO2 emissions. Ultrasonic dehydration employs ultrasonic waves to accelerate moisture removal at lower temperatures, reducing energy consumption by up to 30-40%. Environmentally, ultrasonic dehydration offers a smaller carbon footprint and lower thermal degradation, making it a more sustainable option for berry processing. |

Equipment and Setup Requirements for Each Method

Heat dehydration for berries typically requires industrial ovens or hot air dryers equipped with temperature and humidity controls to ensure consistent drying without damaging the fruit's nutritional value. Ultrasonic dehydration involves ultrasonic transducers and specialized chambers that use high-frequency sound waves to accelerate moisture removal, demanding advanced setup and precise calibration. Heat dehydration systems are generally simpler and more cost-effective, while ultrasonic equipment involves higher initial investment but offers faster drying times and energy efficiency.

Cost Analysis: Heat vs Ultrasonic Dehydration

Heat dehydration methods for berries typically incur lower initial equipment costs compared to ultrasonic dehydration systems but require higher energy consumption over time. Ultrasonic dehydration offers increased efficiency and faster drying times, reducing operational costs despite higher upfront investment.

Maintaining heat dehydration units generally involves less expensive repairs, whereas ultrasonic equipment demands specialized maintenance, contributing to ongoing expenses. When analyzing total cost of ownership, ultrasonic dehydration can provide long-term savings through improved throughput and product quality, offsetting initial higher costs.

Related Important Terms

Thermoconductive Dehydration Efficiency

Heat dehydration relies on thermoconductive properties to efficiently transfer heat through berry surfaces, promoting moisture evaporation but often causing uneven drying and nutrient loss. Ultrasonic dehydration enhances thermoconductive efficiency by generating micro-cavitation and vibrations that accelerate moisture diffusion and preserve berry texture and bioactive compounds.

Ultrasonic-Assisted Water Diffusion

Ultrasonic-assisted water diffusion enhances the dehydration of berries by creating microchannels that accelerate moisture removal, resulting in faster drying times and improved retention of flavor, color, and nutrients compared to conventional heat dehydration. This technique leverages high-frequency sound waves to disrupt cellular structures, increasing water diffusivity and reducing thermal degradation in delicate berry tissues.

Volatile Retention Score

Heat dehydration of berries typically results in lower Volatile Retention Scores due to the loss of aroma compounds at high temperatures, whereas ultrasonic dehydration preserves more volatiles by using low-frequency vibrations that minimize heat exposure. The enhanced retention of delicate flavor molecules during ultrasonic dehydration leads to superior sensory qualities and stronger berry aroma profiles.

Acoustic Cavitation Dehydration

Acoustic cavitation dehydration leverages ultrasonic waves to create microscopic bubbles that implode, efficiently removing moisture from berries without compromising their nutritional content or texture. This method offers faster dehydration rates and improved preservation of flavor compared to traditional heat dehydration, which can degrade heat-sensitive compounds and alter berry quality.

Pulsed Ultrasound Desorption

Pulsed Ultrasound Desorption enhances ultrasonic dehydration efficiency for berries by generating microbubbles and acoustic cavitation, which accelerates moisture removal without compromising nutritional quality. Compared to traditional heat dehydration, this method significantly reduces drying time and preserves bioactive compounds, resulting in superior texture and flavor retention.

Berry Microstructure Preservation Index

Heat dehydration reduces moisture in berries by thermal evaporation but often damages cell walls, resulting in a lower Berry Microstructure Preservation Index due to cellular shrinkage and structural collapse. Ultrasonic dehydration employs high-frequency sound waves to enhance moisture removal while maintaining cell integrity, yielding a significantly higher Berry Microstructure Preservation Index and better preserving natural berry texture and nutritional content.

Heat Denaturation Threshold

Heat dehydration of berries often risks surpassing the heat denaturation threshold, leading to protein breakdown and loss of nutritional quality, whereas ultrasonic dehydration operates below this threshold, preserving structural integrity and bioactive compounds more effectively. Ultrasonic methods enhance moisture removal at lower temperatures, reducing thermal damage and maintaining berry flavor and texture.

Sonodehydration Kinetics

Sonodehydration kinetics in ultrasonic dehydration significantly accelerate moisture removal from berries compared to conventional heat dehydration by generating cavitation effects that disrupt cellular structures and enhance mass transfer rates. This method reduces dehydration time while preserving the berries' phenolic compounds and flavor profile more effectively than heat dehydration.

Phytochemical Retention Ratio

Ultrasonic dehydration preserves a higher phytochemical retention ratio in berries compared to traditional heat dehydration, maintaining more antioxidants and vitamins crucial for health benefits. This method minimizes thermal degradation, optimizing the nutritional and functional quality of the dried fruit.

Heat dehydration vs Ultrasonic dehydration for berries. Infographic

cookingdiff.com

cookingdiff.com