Tray dehydrators use low heat and airflow to remove moisture from pet food, preserving nutrients while maintaining a chewy texture. Freeze dryers, on the other hand, remove moisture through a freezing and vacuum process, resulting in lightweight, shelf-stable treats with maximum nutrient retention. Choosing between the two depends on your preference for texture, storage life, and budget.

Table of Comparison

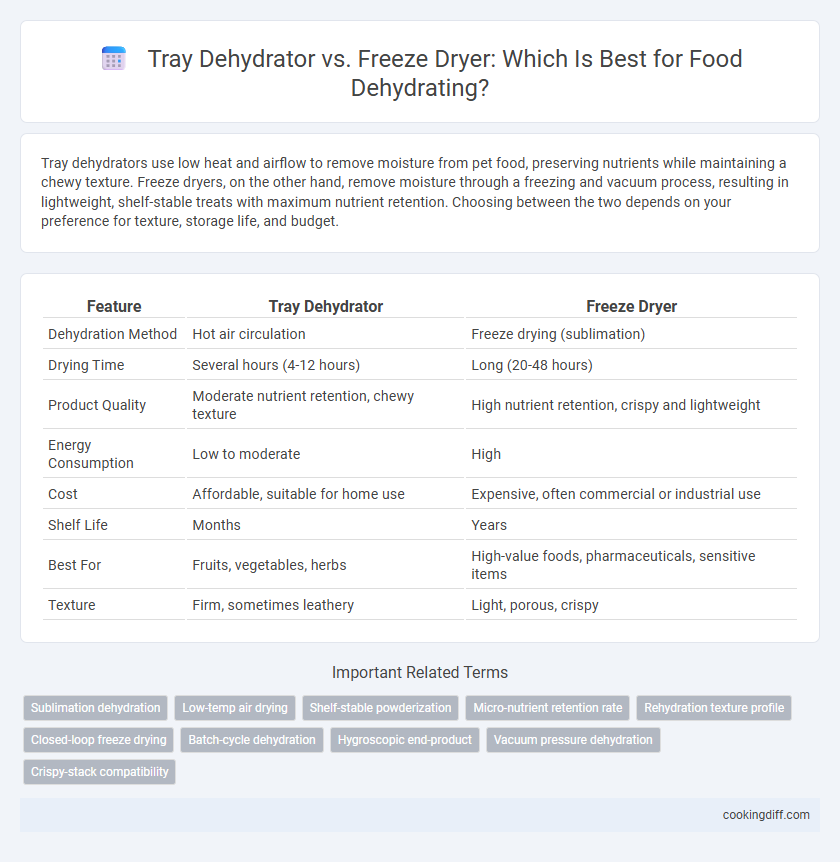

| Feature | Tray Dehydrator | Freeze Dryer |

|---|---|---|

| Dehydration Method | Hot air circulation | Freeze drying (sublimation) |

| Drying Time | Several hours (4-12 hours) | Long (20-48 hours) |

| Product Quality | Moderate nutrient retention, chewy texture | High nutrient retention, crispy and lightweight |

| Energy Consumption | Low to moderate | High |

| Cost | Affordable, suitable for home use | Expensive, often commercial or industrial use |

| Shelf Life | Months | Years |

| Best For | Fruits, vegetables, herbs | High-value foods, pharmaceuticals, sensitive items |

| Texture | Firm, sometimes leathery | Light, porous, crispy |

Introduction to Food Dehydration Methods

| Tray dehydrators remove moisture from food by circulating warm air over multiple trays, preserving texture and flavor efficiently at temperatures typically between 95degF and 155degF. Freeze dryers, or lyophilizers, freeze food before reducing surrounding pressure to sublimate ice directly into vapor, retaining nutritional content and extending shelf life significantly longer. The choice between these methods depends on factors like processing time, cost, and desired food quality, with tray dehydrators offering affordability and speed, while freeze dryers provide superior nutrient preservation and texture maintenance. |

Overview: Tray Dehydrators vs Freeze Dryers

Which method provides better nutrient retention: tray dehydrators or freeze dryers? Tray dehydrators use low heat and airflow to remove moisture, preserving texture with moderate nutrient retention. Freeze dryers utilize sublimation under low temperatures, maintaining higher nutrient content and flavor while extending shelf life significantly.

How Tray Dehydrators Work

Tray dehydrators remove moisture from food by circulating warm air over multiple stacked trays, allowing even drying without freezing. This method uses controlled low heat and airflow to evaporate water content, preserving nutrients while preventing spoilage. Compared to freeze dryers, tray dehydrators are more energy-efficient and cost-effective but may result in a chewier texture and longer drying times.

How Freeze Dryers Operate

Freeze dryers operate by freezing the food and then reducing the surrounding pressure to allow the frozen water in the food to sublimate directly from ice to vapor. This process preserves more nutrients and flavor compared to traditional dehydration methods.

Tray dehydrators use heated air to remove moisture by evaporation, which can lead to nutrient loss and texture change. Freeze drying maintains the structural integrity of the food by avoiding the liquid phase during drying. The low-temperature, vacuum environment in freeze dryers results in longer shelf life and better preservation of color and taste.

Key Differences in Dehydrating Processes

Tray dehydrators use low heat and airflow to remove moisture from food, preserving texture and flavor through gradual drying. Freeze dryers employ sublimation by freezing food and then reducing pressure to remove water, maintaining nutritional content and structure more effectively.

- Temperature Range - Tray dehydrators operate between 95degF and 160degF, while freeze dryers use freezing temperatures below 0degF.

- Drying Time - Tray dehydrating typically takes several hours to a day, whereas freeze drying can take 24 to 48 hours or more.

- Product Quality - Freeze drying retains more nutrients and flavor due to low-temperature dehydration, whereas tray drying may cause slight nutrient loss.

Choosing between tray dehydrators and freeze dryers depends on desired food quality, budget, and drying speed preferences.

Nutritional Retention: Tray vs Freeze Dry

Tray dehydrators use low heat and airflow to remove moisture, which can lead to moderate nutrient loss, particularly of heat-sensitive vitamins like vitamin C and some B vitamins. Freeze dryers preserve nutrients more effectively by freezing food and sublimating moisture, maintaining higher levels of antioxidants, enzymes, and vitamins.

Studies show freeze drying retains up to 97% of nutrients compared to tray dehydration, which typically preserves around 60-70%. The superior nutrient retention makes freeze drying ideal for long-term storage of fruits, vegetables, and herbs where maintaining nutritional value is critical.

Texture and Flavor: Comparing Outcomes

Tray dehydrators remove moisture slowly through gentle heat, often resulting in a chewier texture and intensified, but sometimes altered, flavor profiles. Freeze dryers preserve cellular integrity by sublimating ice directly into vapor, maintaining original texture and more natural flavor retention.

- Tray Dehydrators Enhance Chewiness - Heat-driven dehydration causes partial gelatinization of sugars and proteins, making foods denser and chewier.

- Freeze Dryers Preserve Crispness - Freeze drying avoids liquid phase changes that damage food structure, retaining a light, airy texture.

- Flavor Integrity in Freeze Drying - Low-temperature processing reduces flavor loss and oxidation compared to the prolonged heat exposure in tray dehydrating.

Cost and Energy Efficiency Comparison

Tray dehydrators typically cost significantly less than freeze dryers, making them more accessible for home use and small-scale operations. Energy consumption is also lower for tray dehydrators, as freeze dryers require more electricity to maintain freezing temperatures and vacuum conditions.

- Initial Cost - Tray dehydrators are generally priced between $50 and $500, whereas freeze dryers start around $2,000 and can exceed $10,000.

- Operating Cost - Freeze dryers consume up to 5 times more electricity due to their complex refrigeration and vacuum systems.

- Efficiency - Tray dehydrators use simpler heating elements that reduce energy usage and lower overall operational expenses.

Best Uses for Tray Dehydrators vs Freeze Dryers

Tray dehydrators are ideal for drying fruits, vegetables, herbs, and jerky, offering a cost-effective solution for preserving foods with minimal nutritional loss. They use low heat and airflow to remove moisture gradually, which is suitable for home use and small-scale food preservation.

Freeze dryers excel at preserving delicate foods like berries, coffee, and prepared meals by removing moisture through sublimation, maintaining texture, flavor, and nutrients much longer than tray dehydrators. This method is perfect for long-term storage, emergency food supplies, and retaining high nutritional value in freeze-dried products.

Related Important Terms

Sublimation dehydration

Tray dehydrators use hot air to remove moisture through evaporation, whereas freeze dryers employ sublimation dehydration by freezing food and then reducing pressure to convert ice directly into vapor, preserving nutrients and texture more effectively. Sublimation dehydration in freeze drying maintains food quality longer by preventing cell collapse and oxidation, unlike tray dehydrators where heat can degrade sensitive compounds.

Low-temp air drying

Tray dehydrators utilize low-temperature air drying by circulating warm air around food placed on trays, effectively removing moisture while preserving nutrients and texture. Freeze dryers, although capable of low-temperature processing, primarily use sublimation under vacuum, making tray dehydrators more energy-efficient and cost-effective for simple low-temp air drying applications.

Shelf-stable powderization

Tray dehydrators remove moisture through low heat and air circulation, producing shelf-stable powders suitable for many fruits and herbs but with some nutrient degradation. Freeze dryers sublimate frozen food under low pressure, preserving maximum nutrients and flavor while yielding highly porous, shelf-stable powders with extended shelf life.

Micro-nutrient retention rate

Tray dehydrators typically retain 50-70% of micro-nutrients due to moderate heat exposure, whereas freeze dryers preserve up to 90-95% by sublimating moisture under low temperatures, minimizing nutrient degradation. The superior micro-nutrient retention rate in freeze drying makes it ideal for preserving vitamins and antioxidants in fruits, vegetables, and herbs.

Rehydration texture profile

Tray dehydrators produce dehydrated foods with a firmer, chewier texture upon rehydration due to slow moisture removal at moderate temperatures, preserving cell structure but leading to tougher rehydrated products. Freeze dryers maintain cellular integrity better by sublimating ice directly to vapor under low temperature and pressure, resulting in rehydrated foods with a softer, more natural texture closely resembling the fresh original.

Closed-loop freeze drying

Closed-loop freeze drying preserves nutrient content and flavor by sublimating moisture under vacuum in a sealed environment, minimizing oxidation and contamination compared to tray dehydrators that use heated air for dehydration. The closed-loop system recycles cooling agents and maintains precise temperature control, resulting in higher quality, longer shelf-life dehydrated products ideal for sensitive foods and pharmaceuticals.

Batch-cycle dehydration

Tray dehydrators offer efficient batch-cycle dehydration by circulating warm air over stacked trays, preserving texture and flavor in fruits and vegetables. Freeze dryers, while more costly and time-consuming, provide superior moisture removal and nutrient retention through sublimation, ideal for delicate or long-term food preservation.

Hygroscopic end-product

Tray dehydrators produce hygroscopic end-products by removing moisture steadily through warm air circulation but often leave residual water activity that can attract humidity. Freeze dryers, using sublimation at low temperatures, create highly porous, non-hygroscopic products that retain structural integrity and resist moisture uptake during storage.

Vacuum pressure dehydration

Tray dehydrators operate by circulating heated air over food items to remove moisture, relying primarily on temperature and airflow without vacuum pressure; in contrast, freeze dryers use vacuum pressure combined with low temperatures to sublimate ice directly from frozen food, preserving texture and nutrients more effectively. Vacuum pressure dehydration in freeze dryers reduces oxidation and microbial growth, resulting in higher-quality preservation compared to conventional tray dehydrators.

Tray dehydrator vs Freeze dryer for dehydrating. Infographic

cookingdiff.com

cookingdiff.com