Traditional rack drying of mushrooms relies on air circulation and higher temperatures, often leading to uneven moisture removal and potential loss of flavor and nutrients. Low-temperature dehydration preserves the mushrooms' delicate texture and nutritional profile by gently removing moisture without overheating. This method ensures better retention of color, aroma, and bioactive compounds, making it a superior choice for high-quality mushroom preservation.

Table of Comparison

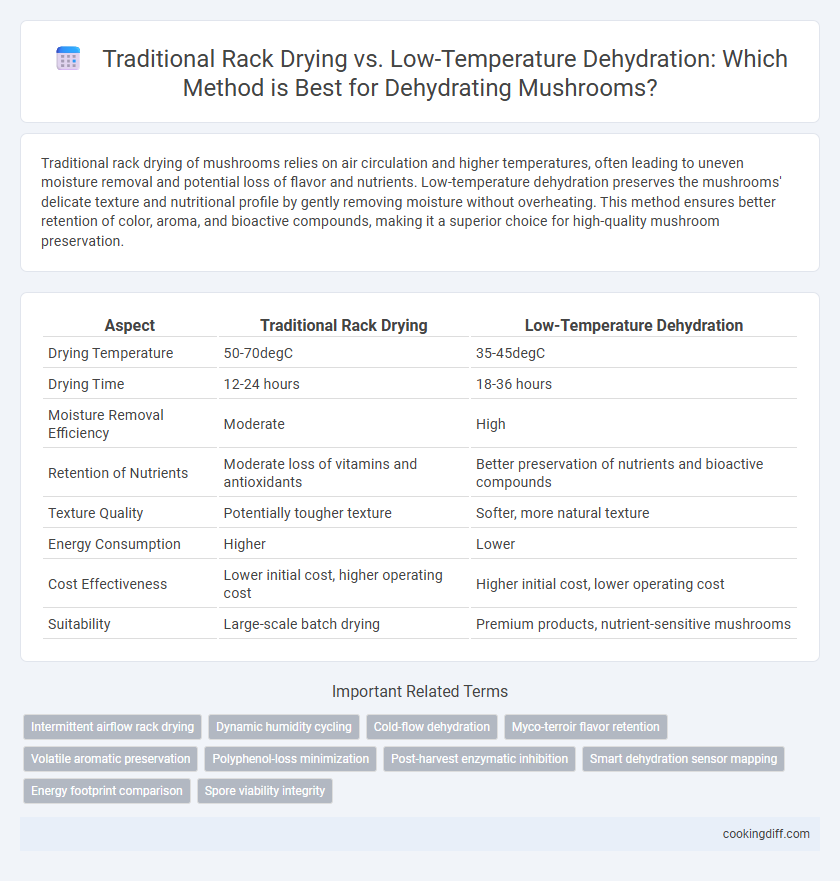

| Aspect | Traditional Rack Drying | Low-Temperature Dehydration |

|---|---|---|

| Drying Temperature | 50-70degC | 35-45degC |

| Drying Time | 12-24 hours | 18-36 hours |

| Moisture Removal Efficiency | Moderate | High |

| Retention of Nutrients | Moderate loss of vitamins and antioxidants | Better preservation of nutrients and bioactive compounds |

| Texture Quality | Potentially tougher texture | Softer, more natural texture |

| Energy Consumption | Higher | Lower |

| Cost Effectiveness | Lower initial cost, higher operating cost | Higher initial cost, lower operating cost |

| Suitability | Large-scale batch drying | Premium products, nutrient-sensitive mushrooms |

Introduction to Mushroom Dehydration Methods

| Traditional rack drying relies on natural airflow and ambient temperatures, which can result in uneven moisture removal and longer drying times for mushrooms. |

| Low-temperature dehydration utilizes controlled heat settings, typically between 50-60degC, preserving mushroom texture, flavor, and nutritional value more effectively. |

| Choosing between these methods depends on desired quality, efficiency, and the scale of mushroom processing operations. |

Overview of Traditional Rack Drying

Traditional rack drying involves spreading mushrooms on mesh racks exposed to ambient air or heated airflow to remove moisture slowly. This method relies on natural evaporation and airflow, often requiring several hours to days to achieve desired dryness levels.

Traditional rack drying is energy-efficient but time-consuming, making it suitable for small-scale mushroom producers. The process can lead to uneven drying and potential contamination due to prolonged exposure to open air. It preserves some mushroom flavor but may degrade nutritional content compared to more controlled methods.

Understanding Low-Temperature Dehydration

Low-temperature dehydration preserves the nutritional content and delicate texture of mushrooms more effectively than traditional rack drying. This method utilizes controlled temperatures below 50degC to prevent the loss of bioactive compounds and maintain flavor integrity. Energy efficiency and extended shelf life are additional benefits of low-temperature dehydration in mushroom processing.

Efficiency and Time Comparison

Traditional rack drying of mushrooms typically requires longer drying times, often ranging from 12 to 24 hours, leading to higher energy consumption and lower overall efficiency. Low-temperature dehydration uses precise temperature control around 40-50degC, significantly reducing drying time to 6-10 hours while preserving nutritional quality. This method enhances efficiency by minimizing moisture loss without overheating, ultimately optimizing both energy use and product quality.

Impact on Mushroom Flavor and Texture

How does traditional rack drying compare to low-temperature dehydration in preserving mushroom flavor and texture? Traditional rack drying often results in uneven drying and a tougher texture, which can diminish the delicate flavors of mushrooms. Low-temperature dehydration maintains a more consistent moisture level, preserving the mushroom's natural umami and yielding a tender, flavorful final product.

Nutrient Retention Analysis

Low-temperature dehydration preserves higher levels of vitamins and antioxidants in mushrooms compared to traditional rack drying, which often leads to significant nutrient loss due to prolonged exposure to heat and air. Studies show that enzymatic activity and bioactive compounds remain more stable during low-temperature methods, ensuring better nutrient retention.

- Vitamin Content - Low-temperature dehydration retains up to 30% more vitamin C than traditional rack drying.

- Antioxidants - Phenolic compounds degrade slower in low-temperature processes, maintaining antioxidant capacity.

- Enzyme Activity - Enzymes crucial for flavor and health benefits exhibit higher activity post-dehydration under controlled low heat.

Choosing low-temperature dehydration optimizes nutrient preservation in dried mushrooms, enhancing their health benefits and quality.

Equipment and Setup Requirements

Traditional rack drying for mushrooms requires sturdy wooden or metal racks placed in well-ventilated spaces, often supplemented with fans to ensure airflow. This method relies on ambient temperature and humidity, necessitating ample space and manual monitoring to prevent spoilage.

Low-temperature dehydration utilizes electric dehydrators equipped with thermostats and adjustable airflow, allowing precise control over drying conditions. The compact design of these devices minimizes space requirements and automates the process, enhancing efficiency and consistency in mushroom dehydration.

Suitability for Different Mushroom Varieties

Traditional rack drying is more suitable for hardy mushroom varieties like shiitake and portobello due to its higher temperature and airflow, which effectively reduces moisture content. Low-temperature dehydration preserves delicate mushrooms such as enoki and morels by retaining their texture and flavor through gentler drying conditions.

- Traditional rack drying favors robust mushrooms - It uses higher heat and airflow ideal for thick-fleshed varieties that tolerate more intense dehydration.

- Low-temperature dehydration suits fragile mushrooms - It maintains the integrity and delicate characteristics of mushrooms sensitive to heat.

- Mushroom variety influences dehydration method choice - Selecting the appropriate drying technique optimizes quality and shelf-life depending on mushroom type.

Cost and Energy Considerations

Traditional rack drying for mushrooms typically incurs higher energy consumption due to prolonged drying times and elevated temperatures. Low-temperature dehydration offers a more energy-efficient alternative by preserving mushroom quality while reducing operational costs.

- Energy Use - Traditional rack drying consumes up to 30% more energy because of extended drying periods at high heat.

- Operational Costs - Low-temperature dehydration lowers electricity bills by maintaining optimal drying conditions without overheating.

- Equipment Investment - Initial setup costs for low-temperature dehydration can be higher but lead to long-term savings through reduced energy demands.

Related Important Terms

Intermittent airflow rack drying

Intermittent airflow rack drying in traditional methods uses controlled bursts of air to efficiently remove moisture from mushrooms while preserving texture and flavor. This approach contrasts with low-temperature dehydration by balancing drying speed and quality retention without prolonged heat exposure that can degrade bioactive compounds.

Dynamic humidity cycling

Dynamic humidity cycling in traditional rack drying of mushrooms often leads to uneven moisture removal and extended drying times, increasing the risk of microbial growth. Low-temperature dehydration utilizes controlled humidity fluctuations to enhance water evaporation uniformly, preserving mushroom quality and nutritional content more effectively.

Cold-flow dehydration

Cold-flow dehydration in low-temperature mushroom drying preserves delicate nutrients and flavors by maintaining temperatures below 40degC, contrasting traditional rack drying which often exposes mushrooms to higher heat, causing texture and nutrient degradation. This method enhances shelf life and quality by using controlled airflow to efficiently remove moisture while minimizing thermal damage.

Myco-terroir flavor retention

Traditional rack drying often leads to uneven moisture removal and flavor loss in mushrooms, compromising the delicate myco-terroir profile. Low-temperature dehydration preserves the unique myco-terroir flavor by maintaining enzymatic activity and preventing heat-induced degradation of volatile aromatic compounds.

Volatile aromatic preservation

Traditional rack drying often causes significant loss of volatile aromatic compounds in mushrooms due to prolonged exposure to higher temperatures and air flow. Low-temperature dehydration techniques better preserve these delicate volatiles by maintaining cooler temperatures, resulting in enhanced aroma retention and flavor intensity.

Polyphenol-loss minimization

Low-temperature dehydration preserves significantly higher levels of polyphenols in mushrooms compared to traditional rack drying, which often causes polyphenol degradation due to prolonged exposure to elevated heat. Studies reveal that maintaining drying temperatures below 50degC during dehydration minimizes oxidative losses, thereby enhancing the retention of bioactive compounds essential for antioxidant activity.

Post-harvest enzymatic inhibition

Low-temperature dehydration effectively inhibits post-harvest enzymatic activity in mushrooms by preserving bioactive compounds and preventing discoloration, unlike traditional rack drying that often results in higher enzymatic degradation due to elevated temperatures. This method enhances shelf life and maintains nutritional quality by slowing enzymatic reactions responsible for spoilage.

Smart dehydration sensor mapping

Smart dehydration sensor mapping enhances precision in both traditional rack drying and low-temperature dehydration for mushrooms by continuously monitoring moisture levels and temperature gradients. This technology optimizes drying efficiency and preserves mushroom quality by adjusting conditions in real-time to prevent overdrying and nutrient loss.

Energy footprint comparison

Traditional rack drying of mushrooms typically consumes more energy due to prolonged exposure to higher temperatures and airflow requirements, resulting in a larger carbon footprint. Low-temperature dehydration uses controlled heat and reduced drying time, significantly lowering energy consumption and contributing to a more sustainable, eco-friendly process.

Traditional rack drying vs Low-temperature dehydration for mushrooms. Infographic

cookingdiff.com

cookingdiff.com