Dehydrating fruit chips results in a consistent texture and longer shelf life compared to sun drying, which can be uneven and susceptible to contamination. Controlled temperature and airflow in dehydrators preserve nutrients and flavor more effectively than the unpredictable conditions of sun drying. This method reduces drying time and minimizes the risk of spoilage, ensuring high-quality fruit chips.

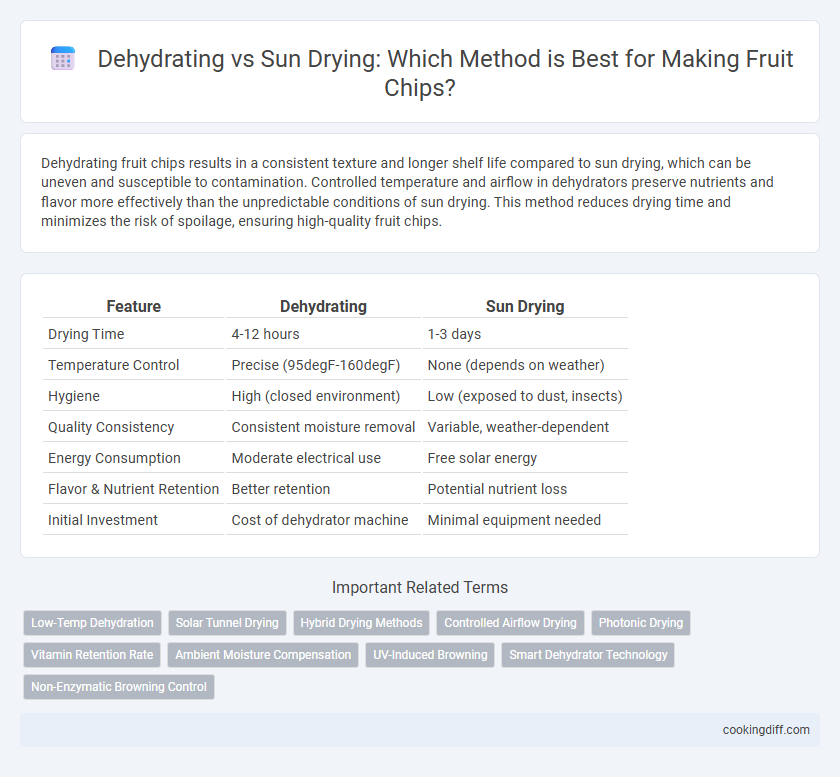

Table of Comparison

| Feature | Dehydrating | Sun Drying |

|---|---|---|

| Drying Time | 4-12 hours | 1-3 days |

| Temperature Control | Precise (95degF-160degF) | None (depends on weather) |

| Hygiene | High (closed environment) | Low (exposed to dust, insects) |

| Quality Consistency | Consistent moisture removal | Variable, weather-dependent |

| Energy Consumption | Moderate electrical use | Free solar energy |

| Flavor & Nutrient Retention | Better retention | Potential nutrient loss |

| Initial Investment | Cost of dehydrator machine | Minimal equipment needed |

Introduction to Fruit Chip Preservation Methods

| Dehydrating fruit chips involves using controlled low heat and airflow to remove moisture, resulting in uniform texture and higher nutrient retention compared to sun drying. Sun drying relies on natural sunlight and ambient temperature, which can vary, leading to inconsistent drying times and potential microbial contamination. Dehydration machines offer efficient, hygienic preservation, extending shelf life while maintaining flavor and nutritional quality. |

What is Dehydrating?

Dehydrating is a controlled method of removing moisture from fruit using low temperatures and circulated air to preserve nutrients and extend shelf life. Unlike sun drying, dehydrating maintains consistent heat and hygiene, reducing the risk of contamination and uneven drying. This process results in fruit chips with a uniform texture and enhanced flavor retention.

Understanding Sun Drying for Fruits

Sun drying fruits involves placing them under direct sunlight to naturally remove moisture, which can take several days depending on weather conditions. This method is cost-effective and environmentally friendly but may lead to inconsistent drying and potential contamination from insects or dust. Understanding the limitations of sun drying helps in choosing suitable fruits and preparing them properly to ensure safety and quality in fruit chip production.

Equipment and Setup: Dehydrator vs Sun Drying

Dehydrators provide controlled temperatures and airflow, enabling consistent drying of fruit chips regardless of weather conditions. Sun drying depends on direct sunlight and ambient temperature, which can vary widely and affect the drying time and quality.

- Dehydrator Equipment - Electric units with adjustable temperature settings and built-in fans optimize moisture removal efficiently.

- Sun Drying Setup - Requires open, sunny spaces with protective mesh covers to shield fruit from insects and debris.

- Drying Control - Dehydrators offer precise control over drying parameters, while sun drying is subject to environmental inconsistencies.

Time and Efficiency Comparison

Dehydrating fruit chips offers a significantly faster drying time compared to traditional sun drying, reducing the process from days to several hours. Efficiency improves with precise temperature and humidity control, ensuring consistent quality and preventing spoilage.

- Time Efficiency - Dehydrators typically dry fruit chips in 6-12 hours, whereas sun drying can take 2-5 days depending on weather conditions.

- Energy Use - Sun drying requires no electricity but depends on sunlight availability, making it less reliable and slower.

- Quality Control - Dehydrators maintain uniform drying environments, reducing contamination and retaining nutrients better than sun drying.

Overall, dehydrating provides a quicker, more controlled method for producing high-quality fruit chips compared to sun drying.

Impact on Nutritional Value

How does dehydrating compare to sun drying in preserving the nutritional value of fruit chips? Dehydrating fruit chips retains more vitamins, especially vitamin C, due to controlled low temperatures and faster moisture removal. Sun drying exposes fruit to longer periods of heat and light, leading to greater nutrient degradation and potential loss of antioxidants.

Flavor and Texture Differences

Dehydrating fruit chips preserves a more uniform sweetness and intense fruit flavor due to controlled low temperatures that prevent caramelization. This method maintains a tender yet slightly chewy texture that enhances snacking experience compared to sun drying.

Sun drying exposes fruits to inconsistent heat and light, leading to a more caramelized, sometimes slightly bitter flavor profile. The texture is typically tougher and drier, which can result in a less pleasant mouthfeel than dehydrated fruit chips.

Safety and Food Hygiene Considerations

Dehydrating fruit chips in a controlled environment reduces the risk of contamination from airborne particles and insects, ensuring higher food safety compared to sun drying. Temperature regulation during dehydration inhibits microbial growth, maintaining optimal hygiene standards throughout the drying process.

Sun drying exposes fruit chips to unpredictable weather and pests, increasing the likelihood of contamination and spoilage. Proper handling and sanitation are crucial to mitigate hygiene risks when using sun drying methods for fruit preservation.

Cost and Energy Consumption

Dehydrating fruit chips requires a higher initial investment in specialized equipment compared to sun drying, but it significantly reduces energy consumption per batch due to controlled temperature settings. Sun drying has minimal upfront costs but depends heavily on weather conditions, leading to inconsistent energy use and longer processing times.

- Initial Cost - Dehydrators entail purchasing electric or gas-powered machines, increasing startup expenses.

- Energy Efficiency - Dehydrators optimize energy use by maintaining consistent heat, reducing overall consumption.

- Operational Variability - Sun drying uses natural sunlight, resulting in unpredictable drying times and fluctuating energy needs.

Related Important Terms

Low-Temp Dehydration

Low-temp dehydration preserves more nutrients and natural flavors in fruit chips compared to sun drying by maintaining temperatures below 130degF, which prevents enzymatic browning and microbial growth. This method ensures consistent moisture removal, resulting in a crisp texture and extended shelf life without exposure to contaminants or UV damage.

Solar Tunnel Drying

Solar tunnel drying enhances fruit chip quality by providing consistent temperature control and reduced contamination compared to traditional sun drying. This method accelerates moisture removal while preserving color, flavor, and nutrients through indirect solar heat within a controlled environment.

Hybrid Drying Methods

Hybrid drying methods combine dehydrating and sun drying techniques to optimize moisture removal and preserve nutrient content in fruit chips, enhancing texture and shelf life compared to solely sun drying. This approach utilizes controlled temperature and airflow from dehydrators with natural solar energy, reducing drying time while maintaining flavor and color quality.

Controlled Airflow Drying

Controlled airflow drying offers precise temperature and humidity regulation, ensuring uniform dehydration of fruit chips without nutrient loss or microbial growth that are common risks in sun drying. This method enhances shelf life and maintains optimal texture by preventing contamination and uneven drying typical in traditional sun drying processes.

Photonic Drying

Photonic drying offers precise temperature control and accelerated moisture removal, preserving the color, flavor, and nutrient content of fruit chips better than traditional sun drying. This technology reduces microbial growth and oxidation risks by minimizing exposure to external contaminants, resulting in superior shelf life and product quality compared to the slower, weather-dependent sun drying method.

Vitamin Retention Rate

Dehydrating fruit chips maintains a higher vitamin retention rate compared to sun drying, as controlled temperatures and air circulation reduce nutrient degradation, particularly preserving vitamin C and B-complex vitamins. Sun drying exposes fruit to prolonged heat and UV rays, accelerating vitamin loss and reducing overall nutritional value.

Ambient Moisture Compensation

Dehydrating fruit chips uses controlled temperature and airflow to effectively manage ambient moisture, ensuring consistent drying and preventing spoilage, unlike sun drying which is heavily dependent on unpredictable environmental humidity. This precise ambient moisture compensation in dehydrators enhances texture, prolongs shelf life, and maintains nutritional quality.

UV-Induced Browning

Dehydrating fruit chips minimizes UV-induced browning by using controlled, low-temperature air circulation, preserving color and nutrients more effectively than sun drying. Sun drying exposes fruit to direct sunlight, accelerating enzymatic browning and pigment degradation due to ultraviolet radiation, resulting in less visually appealing and lower-quality chips.

Smart Dehydrator Technology

Smart dehydrator technology enhances fruit chip drying by precisely controlling temperature and airflow, ensuring consistent moisture removal and preserving nutrient content far better than traditional sun drying. Unlike sun drying, which is weather-dependent and risks contamination, smart dehydrators offer hygienic, efficient, and uniform dehydration, resulting in superior shelf life and texture for fruit chips.

Dehydrating vs Sun Drying for fruit chips. Infographic

cookingdiff.com

cookingdiff.com