Rack dehydrating offers superior airflow around each fruit leather piece, ensuring even drying and preventing sticking, while stackable shelf dehydrating saves space but may require rotating trays for uniform results. Fruit leather made using rack dehydrators often has a more consistent texture and faster drying time due to better ventilation. Choosing between the two depends on available space and drying capacity needs, with racks favored for quality and stackable shelves for compact setups.

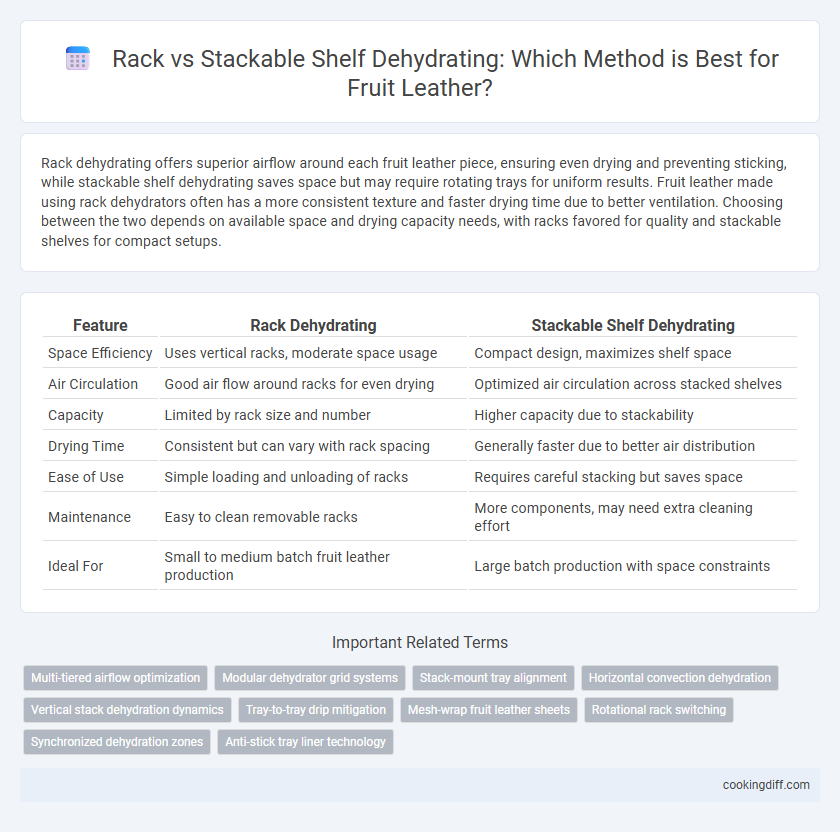

Table of Comparison

| Feature | Rack Dehydrating | Stackable Shelf Dehydrating |

|---|---|---|

| Space Efficiency | Uses vertical racks, moderate space usage | Compact design, maximizes shelf space |

| Air Circulation | Good air flow around racks for even drying | Optimized air circulation across stacked shelves |

| Capacity | Limited by rack size and number | Higher capacity due to stackability |

| Drying Time | Consistent but can vary with rack spacing | Generally faster due to better air distribution |

| Ease of Use | Simple loading and unloading of racks | Requires careful stacking but saves space |

| Maintenance | Easy to clean removable racks | More components, may need extra cleaning effort |

| Ideal For | Small to medium batch fruit leather production | Large batch production with space constraints |

Introduction to Fruit Leather Dehydration Methods

Rack dehydrating uses open, evenly spaced racks that allow consistent air circulation and uniform drying of fruit leather. This method reduces drying time and minimizes the risk of moisture pockets that can lead to spoilage.

Stackable shelf dehydrating involves layering fruit leather sheets on shelves that fit into a compact drying unit, optimizing space but potentially restricting airflow. Proper rotation and spacing are critical to ensure even dehydration and achieve the desired texture and shelf life.

What Is Rack Dehydrating?

Rack dehydrating involves placing fruit leather on multiple horizontal racks within a dehydrator, allowing for even air circulation and consistent drying. This method maximizes space and ensures uniform texture by preventing overlapping or folding of the fruit leather. Rack dehydrators are preferred for their efficiency in handling large batches with consistent heat distribution.

What Are Stackable Shelf Dehydrators?

What are stackable shelf dehydrators and how do they differ from rack dehydrators for fruit leather? Stackable shelf dehydrators feature multiple removable trays that allow for even air circulation and consistent drying of fruit leather slices. This design enhances drying efficiency by maximizing airflow and providing greater flexibility in batch sizes compared to traditional rack dehydrators.

Drying Efficiency: Rack vs Stackable Shelf

Rack dehydrating offers superior air circulation around fruit leather, promoting faster and more even drying compared to stackable shelf systems. Stackable shelf dehydrators save space but may experience slower drying times due to restricted airflow between trays.

- Rack Dehydrating provides optimal airflow - Elevated racks allow hot air to circulate freely, reducing drying time for fruit leather.

- Stackable Shelf Dehydrating increases capacity - Multiple trays maximize dehydrator space but can limit air circulation efficiency.

- Drying uniformity varies by method - Rack systems typically produce more consistent dehydration across all fruit leather layers.

Airflow and Heat Distribution Differences

Rack dehydrating offers superior airflow by allowing air to circulate freely around each tray, resulting in more even heat distribution for consistent fruit leather drying. Stackable shelf dehydrators tend to restrict airflow between shelves, causing uneven heat exposure and potential drying inconsistencies in thicker or denser pieces.

- Rack Design Enhances Airflow - Open racks facilitate optimal air circulation, preventing moisture buildup on the fruit leather surface.

- Heat Distribution is More Uniform in Racks - Even spacing allows heat to disperse evenly, reducing drying time and risk of under-processed areas.

- Stackable Shelves Limit Air Movement - Close stacking creates airflow blockages that can lead to hot and cool spots across the drying trays.

Space Management and Batch Sizes

Rack dehydrating offers superior space management by allowing vertical stacking of trays, maximizing airflow and drying efficiency for large batch sizes of fruit leather. Stackable shelf dehydrating systems provide flexibility by enabling smaller, segmented batches, ideal for limited kitchen spaces and experimental drying. Choosing between these methods depends on production volume and available space, with rack systems favoring bulk processing and stackable shelves accommodating smaller, customizable runs.

Ease of Cleaning and Maintenance

Rack dehydrators feature removable trays that allow easy access for thorough cleaning, reducing residue buildup and preventing mold growth on fruit leather surfaces. The straightforward design minimizes maintenance time by enabling quick disassembly and reassembly.

Stackable shelf dehydrators may have more compact trays that can be harder to clean thoroughly, potentially trapping sticky fruit leather residues. This design often requires more effort to maintain hygiene and prolong appliance lifespan.

Consistency of Fruit Leather Texture

Rack dehydrating ensures uniform air circulation around each piece of fruit leather, resulting in a consistent texture throughout. Stackable shelf dehydrating can create uneven drying due to restricted airflow between layers, leading to variable thickness and chewiness.

Uniform airflow in rack dehydrating promotes even moisture removal, which is essential for maintaining a smooth and pliable fruit leather texture. In contrast, stackable shelves often cause lower shelves to retain more moisture, producing a tackier and less stable product. Choosing the appropriate method directly affects the final quality and shelf-life of fruit leather by improving texture consistency.

Cost and Accessibility Considerations

| Rack dehydrating often involves a higher initial investment due to its larger capacity and durable construction, making it suitable for commercial use but less accessible for casual users. |

| Stackable shelf dehydrating systems offer a cost-effective solution with modular designs, allowing users to start small and expand based on need, which enhances accessibility and reduces upfront expenses. |

| For fruit leather production, stackable shelves provide better flexibility and affordability, while rack dehydrators are more efficient for high-volume operations requiring consistent drying conditions. |

Related Important Terms

Multi-tiered airflow optimization

Rack dehydrating offers superior multi-tiered airflow optimization by allowing consistent air circulation across each layer, enhancing even drying and preventing moisture buildup in fruit leather. Stackable shelf dehydrators may restrict airflow on lower tiers, resulting in uneven dehydration and longer drying times.

Modular dehydrator grid systems

Modular dehydrator grid systems for fruit leather offer customizable rack dehydrating options that ensure even airflow and consistent drying by spacing trays apart vertically. Stackable shelf dehydrating conserves space but may reduce air circulation, risking uneven moisture removal and longer drying times compared to rack systems designed for modular scalability.

Stack-mount tray alignment

Stackable shelf dehydrating offers precise stack-mount tray alignment that ensures uniform airflow and even drying of fruit leather, minimizing curl and stickiness issues. By optimizing tray spacing and airflow pathways, it outperforms rack dehydrating systems in maintaining consistent texture and color across multiple layers.

Horizontal convection dehydration

Rack dehydrating uses a horizontal convection system to evenly circulate warm air across thin layers of fruit leather, ensuring consistent moisture removal and uniform drying. Stackable shelf dehydrating often restricts airflow between layers, potentially causing uneven drying and longer dehydration times for fruit leather.

Vertical stack dehydration dynamics

Rack dehydrating maximizes vertical airflow and heat distribution, ensuring consistent drying for fruit leather by allowing air to circulate freely around each layer. Stackable shelf dehydrators, while space-efficient, can restrict airflow between layers, potentially resulting in uneven dehydration and extended drying times.

Tray-to-tray drip mitigation

Rack dehydrating offers superior tray-to-tray drip mitigation for fruit leather by maintaining ample vertical spacing, preventing liquid runoff from contaminating lower trays. Stackable shelf dehydrators, with closely stacked trays, risk drip accumulation and uneven drying, potentially compromising fruit leather texture and safety.

Mesh-wrap fruit leather sheets

Rack dehydrating with mesh-wrap fruit leather sheets offers better air circulation and even drying compared to stackable shelf dehydrating, which can cause uneven moisture retention due to limited airflow. Mesh-wrap sheets promote consistent dehydration by allowing optimal heat penetration and minimizing the risk of sticking or tearing in fruit leather production.

Rotational rack switching

Rack dehydrating offers efficient rotational rack switching, allowing even airflow and consistent drying of fruit leather across multiple layers, while stackable shelf dehydrators may have limited rotation capability, potentially causing uneven drying. Rotational rack systems reduce drying time and improve texture uniformity by minimizing hotspots typically found in static stackable shelf designs.

Synchronized dehydration zones

Rack dehydrating offers synchronized dehydration zones that ensure even airflow and consistent temperature distribution, critical for uniformly drying fruit leather sheets. Stackable shelf dehydrators often lack this precise zone control, leading to variable moisture levels and inconsistent texture across different shelves.

Rack Dehydrating vs Stackable Shelf Dehydrating for fruit leather. Infographic

cookingdiff.com

cookingdiff.com