Dehydrating jerky with traditional methods often requires higher temperatures and longer drying times, which can risk uneven texture and loss of nutrients. Heat pump drying utilizes lower temperatures and controlled humidity, preserving flavor and texture while reducing energy consumption. This method ensures consistent drying results and enhances the overall quality of homemade jerky.

Table of Comparison

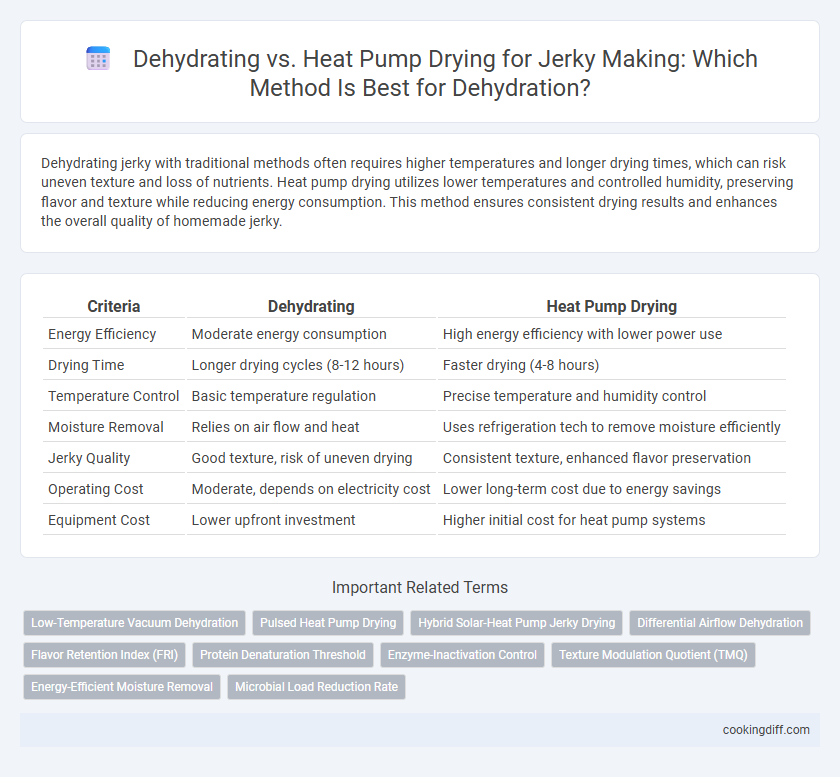

| Criteria | Dehydrating | Heat Pump Drying |

|---|---|---|

| Energy Efficiency | Moderate energy consumption | High energy efficiency with lower power use |

| Drying Time | Longer drying cycles (8-12 hours) | Faster drying (4-8 hours) |

| Temperature Control | Basic temperature regulation | Precise temperature and humidity control |

| Moisture Removal | Relies on air flow and heat | Uses refrigeration tech to remove moisture efficiently |

| Jerky Quality | Good texture, risk of uneven drying | Consistent texture, enhanced flavor preservation |

| Operating Cost | Moderate, depends on electricity cost | Lower long-term cost due to energy savings |

| Equipment Cost | Lower upfront investment | Higher initial cost for heat pump systems |

Introduction to Jerky Making: Traditional vs Modern Drying Methods

Jerky making involves removing moisture from meat to preserve it, using either traditional dehydrating methods or modern heat pump drying. Each technique impacts flavor, texture, and energy efficiency differently.

- Traditional Dehydrating - Uses low heat and air flow to slowly dry meat, enhancing natural flavors but requiring longer drying times.

- Heat Pump Drying - Employs advanced technology to control temperature and humidity, leading to faster drying with energy savings.

- Flavor and Texture Differences - Traditional methods often yield a chewier texture, while heat pump drying produces more consistent results.

What is Dehydrating? Process and Principles

Dehydrating is a food preservation method that removes moisture from jerky to inhibit bacterial growth and extend shelf life. The process relies on low heat and consistent airflow to evaporate water while maintaining the meat's texture and nutrients. This technique contrasts with heat pump drying by using natural convection rather than compressed heat circulation for moisture extraction.

Understanding Heat Pump Drying Technology

Heat pump drying utilizes advanced refrigeration technology to remove moisture from jerky at lower temperatures, preserving flavor and texture more effectively than traditional dehydration methods. This process involves circulating warm air while extracting humidity, resulting in energy-efficient and consistent drying conditions.

- Energy Efficiency - Heat pump dryers consume less energy than conventional dehydrators due to the recycling of heat within the system.

- Temperature Control - Precise temperature regulation prevents over-drying and maintains optimal jerky quality.

- Moisture Removal - Efficient humidity extraction reduces drying time and inhibits microbial growth for safer jerky production.

Understanding heat pump drying technology offers a superior approach to jerky making by combining efficiency, control, and product safety.

Comparing Efficiency: Dehydrators vs Heat Pump Dryers

Dehydrators typically consume more energy than heat pump dryers due to their reliance on direct heating elements, which generate higher temperatures for drying jerky. Heat pump dryers operate at lower temperatures with better energy efficiency by recycling heat within a closed system.

Although dehydrators can achieve faster drying times, heat pump dryers reduce operational costs by using up to 50% less electricity. Heat pump drying maintains consistent humidity and temperature control, resulting in more uniform jerky texture and preservation. The initial investment in heat pump technology is higher, but long-term energy savings often justify the cost for frequent jerky makers.

Flavor and Texture Differences in Jerky

Dehydrating jerky typically produces a chewier texture and more intense, concentrated flavors due to slow moisture removal. Heat pump drying preserves more natural meat flavors and yields a softer, less tough jerky texture by maintaining lower drying temperatures.

- Dehydrating enhances chewiness - The gradual drying process intensifies the jerky's texture and flavor profile.

- Heat pump drying retains moisture - This method results in a tender jerky with balanced flavor preservation.

- Flavor complexity differs - Dehydrating often concentrates spices and seasoning, while heat pump drying maintains subtle, natural meat notes.

Energy Consumption: Costs and Environmental Impact

How does energy consumption compare between dehydrating and heat pump drying methods for jerky making? Dehydrating typically consumes more electricity due to prolonged operation at higher temperatures, leading to increased costs and a larger carbon footprint. Heat pump drying uses a more efficient cycle that reduces energy usage by up to 50%, lowering both operational costs and environmental impact significantly.

Food Safety and Preservation Considerations

Dehydrating jerky at temperatures between 130degF and 160degF effectively removes moisture, reducing bacterial growth and enhancing preservation. Heat pump drying maintains a controlled low-temperature environment with consistent airflow, minimizing oxidation and nutrient loss while ensuring food safety. Both methods require precise temperature monitoring to prevent pathogen survival and maximize shelf life.

Equipment Investment and Maintenance

Dehydrators for jerky making typically require lower initial equipment investment compared to heat pump drying systems, making them more accessible for small-scale producers. Maintenance costs are generally minimal, involving simple cleaning and occasional replacement of heating elements or fans.

Heat pump dryers demand a higher upfront investment due to advanced technology components and more complex design, but they offer improved energy efficiency and longer operational lifespan. Maintenance involves specialized servicing of compressors and refrigerant systems, which can increase long-term upkeep costs.

Suitability for Home and Commercial Jerky Production

Dehydrating using traditional food dehydrators is highly suitable for home jerky production due to its straightforward operation and lower initial cost. Heat pump drying offers precise temperature and humidity control, making it ideal for commercial jerky production where consistency and efficiency are critical.

Home users benefit from dehydrators with adjustable trays and simple settings, ensuring safe and uniform drying without complex equipment. Commercial producers prefer heat pump dryers for their energy efficiency, faster drying times, and ability to handle large batch volumes while maintaining jerky quality.

Related Important Terms

Low-Temperature Vacuum Dehydration

Low-temperature vacuum dehydration preserves jerky's flavor and nutrients by removing moisture under reduced pressure at temperatures below 140degF, minimizing protein denaturation and lipid oxidation compared to heat pump drying. This method enhances texture and shelf life while reducing energy consumption and preventing the case-hardening common in heat pump drying processes.

Pulsed Heat Pump Drying

Pulsed heat pump drying offers precise temperature control and energy efficiency, significantly reducing drying time compared to traditional dehydrating methods for jerky making. This technique maintains the meat's texture and flavor by preventing over-drying and microbial growth through intermittent airflow and temperature modulation.

Hybrid Solar-Heat Pump Jerky Drying

Hybrid solar-heat pump jerky drying maximizes energy efficiency by combining solar thermal input with the precise temperature control of heat pump technology, ensuring consistent moisture removal and optimal flavor retention. This integrated method reduces drying time and operational costs while preserving the nutritional quality and texture of the jerky compared to traditional dehydrating or standalone heat pump drying techniques.

Differential Airflow Dehydration

Differential airflow dehydration in jerky making uses directional air circulation to enhance moisture removal efficiency compared to uniform heat pump drying, resulting in faster drying times and improved texture consistency. This method optimizes airflow velocity and temperature gradients, minimizing enzymatic activity and microbial growth while preserving flavor and nutritional content.

Flavor Retention Index (FRI)

Dehydrating jerky using traditional methods typically maintains a higher Flavor Retention Index (FRI) compared to heat pump drying, preserving more aromatic compounds and natural meat flavors. Heat pump drying, while energy-efficient, can cause a moderate reduction in FRI due to elevated temperatures disrupting flavor profiles during the drying process.

Protein Denaturation Threshold

Dehydrating jerky typically involves temperatures ranging from 130degF to 160degF, which can approach but should not exceed the protein denaturation threshold of approximately 140degF to 155degF to preserve texture and flavor. Heat pump drying offers precise temperature control below this threshold, minimizing protein denaturation while effectively removing moisture and enhancing shelf life.

Enzyme-Inactivation Control

Dehydrating jerky using conventional heat methods may lead to uneven enzyme-inactivation, risking spoilage and compromised texture, whereas heat pump drying ensures precise temperature and humidity control for consistent enzyme-inactivation and enhanced product safety. By maintaining optimal thermal conditions, heat pump drying preserves nutrient quality and extends shelf life more effectively than traditional dehydrating techniques.

Texture Modulation Quotient (TMQ)

Dehydrating jerky maintains a higher Texture Modulation Quotient (TMQ), preserving chewiness and fibrous integrity by evenly removing moisture without overheating. Heat pump drying, while faster, often reduces TMQ due to uneven heat distribution that can cause excessive drying and tougher, brittle textures.

Energy-Efficient Moisture Removal

Dehydrating jerky uses steady low heat and airflow to slowly remove moisture while preserving texture and flavor, consuming more energy over extended drying times. Heat pump drying employs a closed-loop system, recycling heat and reducing electricity usage by up to 50%, making it significantly more energy-efficient for moisture removal in jerky production.

Dehydrating vs Heat Pump Drying for jerky making. Infographic

cookingdiff.com

cookingdiff.com