Sun drying fruit relies on natural sunlight, which can be inconsistent and expose produce to contaminants like dust and insects, potentially compromising quality. Solar dehydrators use controlled heat and airflow, accelerating drying times and producing more uniform, hygienic results. Choosing a solar dehydrator enhances efficiency and preserves flavor and nutrients better than traditional sun drying.

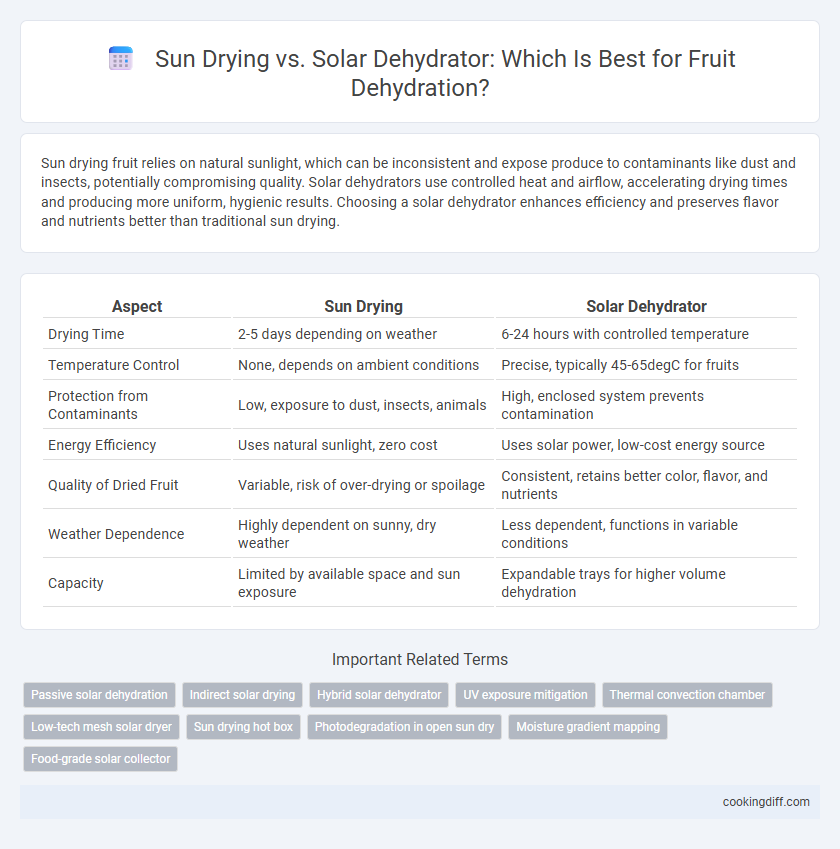

Table of Comparison

| Aspect | Sun Drying | Solar Dehydrator |

|---|---|---|

| Drying Time | 2-5 days depending on weather | 6-24 hours with controlled temperature |

| Temperature Control | None, depends on ambient conditions | Precise, typically 45-65degC for fruits |

| Protection from Contaminants | Low, exposure to dust, insects, animals | High, enclosed system prevents contamination |

| Energy Efficiency | Uses natural sunlight, zero cost | Uses solar power, low-cost energy source |

| Quality of Dried Fruit | Variable, risk of over-drying or spoilage | Consistent, retains better color, flavor, and nutrients |

| Weather Dependence | Highly dependent on sunny, dry weather | Less dependent, functions in variable conditions |

| Capacity | Limited by available space and sun exposure | Expandable trays for higher volume dehydration |

Introduction to Fruit Dehydration Methods

| Sun drying is a traditional fruit dehydration method relying on direct sunlight and ambient air for moisture removal, typically requiring clear, hot weather and posing risks of contamination and uneven drying. Solar dehydrators use controlled solar energy through enclosed structures that provide consistent heat and airflow, enhancing drying efficiency, hygiene, and preserving fruit quality. Choosing between these methods involves considering climate conditions, desired drying speed, and product safety for optimal fruit preservation. |

Principles of Sun Drying

Sun drying relies on natural solar radiation and ambient temperature to remove moisture from fruits, utilizing direct exposure to sunlight and airflow. This traditional method depends heavily on weather conditions, requiring clear, dry days and adequate ventilation to prevent mold growth. The principle involves converting water inside the fruit to vapor, which escapes as the fruit's temperature rises under the sun.

How Solar Dehydrators Work

Solar dehydrators utilize controlled airflow and regulated heat to efficiently remove moisture from fruits, enhancing preservation compared to traditional sun drying. These devices harness solar energy within enclosed chambers, preventing contamination and speeding drying times.

- Solar Energy Absorption - The dehydrator's black surface absorbs sunlight, converting it into heat to raise the internal temperature.

- Air Circulation - Vents and fans promote constant airflow, which carries away moisture from the fruit's surface.

- Temperature Control - The enclosed design maintains consistent heat levels, preventing spoilage and nutrient loss during dehydration.

Key Differences Between Sun Drying and Solar Dehydrators

Sun drying relies on natural sunlight and ambient temperatures, which can lead to inconsistent drying results due to weather variability. Solar dehydrators use controlled airflow and enclosed chambers to achieve more uniform and efficient fruit dehydration.

- Temperature Control - Sun drying depends on fluctuating outdoor temperatures, while solar dehydrators maintain consistent heat levels.

- Protection from Contaminants - Sun drying exposes fruit to dust, insects, and animals, whereas solar dehydrators provide a protective enclosure.

- Drying Speed - Solar dehydrators typically reduce drying time by improving air circulation compared to slower sun drying.

Choosing a solar dehydrator enhances fruit preservation quality and hygiene over traditional sun drying methods.

Efficiency and Drying Time Comparison

Sun drying relies on natural sunlight and ambient conditions, often requiring several days to dehydrate fruit completely, resulting in variable drying efficiency. Solar dehydrators use controlled heat and airflow to significantly reduce drying time, enhancing consistency and preserving fruit quality.

- Sun drying efficiency - Dependent on weather, sun drying can have inconsistent results with potential contamination risks.

- Solar dehydrator efficiency - Provides a controlled environment that improves dehydration rate and product safety.

- Drying time comparison - Solar dehydrators typically dry fruit in 12-24 hours compared to 2-4 days with sun drying.

Effects on Fruit Quality and Nutrition

Sun drying often leads to uneven dehydration and greater exposure to contaminants, which can degrade fruit quality and reduce nutrient retention. Prolonged drying times under direct sunlight increase the risk of oxidative damage, diminishing vitamins such as vitamin C and carotenoids.

Solar dehydrators provide controlled temperature and airflow, enhancing uniform drying and preserving the fruit's color, texture, and nutritional value. By minimizing exposure to UV rays and contaminants, solar dehydrators effectively maintain higher levels of antioxidants and essential nutrients.

Safety and Hygiene Considerations

Sun drying exposes fruits to open air, increasing the risk of contamination from dust, insects, and animal activity, which can compromise safety and hygiene. In contrast, solar dehydrators provide a controlled environment that minimizes exposure to external pollutants and pests, enhancing food safety.

Solar dehydrators often include features such as mesh screens and enclosed chambers that help maintain cleanliness and reduce microbial growth. This controlled method ensures better hygiene throughout the dehydration process, leading to a safer final product for consumption.

Cost and Accessibility Factors

Sun drying fruit requires minimal initial investment, making it highly accessible for individuals in regions with abundant sunlight but lacks controlled conditions, which can lead to inconsistent quality. Solar dehydrators involve higher upfront costs due to materials and design but offer more efficient drying times and better protection against contaminants. Cost-effectiveness depends on budget availability and the need for reliability, with sun drying favored for low-cost accessibility and solar dehydrators preferred for improved fruit preservation and scalability.

Suitable Fruits for Each Dehydration Method

Which fruits are best suited for sun drying compared to solar dehydrators? High-sugar fruits like grapes, figs, and apricots are ideal for sun drying due to their quick dehydration and lower risk of spoilage. Solar dehydrators are better for moisture-rich fruits such as berries, apples, and peaches, as they provide controlled temperature and airflow for consistent drying.

Related Important Terms

Passive solar dehydration

Sun drying relies solely on natural sunlight and ambient air circulation, often resulting in inconsistent drying times and higher susceptibility to contamination and spoilage. Passive solar dehydrators enhance fruit dehydration efficiency by utilizing greenhouse-like enclosures that trap heat and maintain steady airflow, ensuring more uniform drying while reducing exposure to pests and environmental pollutants.

Indirect solar drying

Indirect solar drying uses a solar collector to absorb and convert sunlight into heat, which is then transferred to the drying chamber, preventing direct exposure of fruit to sunlight and reducing nutrient loss. Compared to traditional sun drying, this method improves drying efficiency, ensures uniform moisture removal, and enhances fruit quality by minimizing contamination and oxidation.

Hybrid solar dehydrator

Hybrid solar dehydrators combine the efficiency of direct sun drying with controlled airflow and temperature regulation, significantly reducing dehydration time and preserving nutrient content in fruits. This method outperforms traditional sun drying by minimizing contamination and moisture retention, ensuring higher quality and longer shelf life for dried fruit products.

UV exposure mitigation

Solar dehydrators significantly reduce UV exposure compared to traditional sun drying by enclosing fruits within UV-filtering materials, preserving nutrient integrity and preventing discoloration. In contrast, direct sun drying exposes fruits to harmful ultraviolet rays, accelerating degradation and compromising quality.

Thermal convection chamber

Sun drying exposes fruit to inconsistent temperatures and contaminants, resulting in uneven dehydration and potential spoilage, whereas a solar dehydrator with a thermal convection chamber provides controlled airflow and uniform heat distribution, enhancing drying efficiency and preserving fruit quality. The thermal convection chamber optimizes heat transfer by circulating warm air evenly around the fruit, reducing drying time and minimizing nutrient loss compared to traditional sun drying methods.

Low-tech mesh solar dryer

Low-tech mesh solar dryers offer a cost-effective, energy-efficient alternative to traditional sun drying by providing better protection against contaminants and insects while maintaining optimal airflow for uniform fruit dehydration. These mesh solar dryers reduce drying time by trapping heat more effectively, preserving nutrients and enhancing the shelf life of dehydrated fruits compared to open-air sun drying methods.

Sun drying hot box

Sun drying with a hot box relies on direct exposure to sunlight and ambient heat to remove moisture from fruits, offering a low-cost and energy-efficient dehydration method. Unlike solar dehydrators, which use controlled airflow and enclosed environments to enhance drying speed and consistency, sun drying hot boxes may have longer drying times and higher susceptibility to contamination and uneven drying.

Photodegradation in open sun dry

Sun drying exposes fruits to direct ultraviolet (UV) radiation, accelerating photodegradation that causes loss of color, nutrients, and antioxidant properties. Solar dehydrators minimize UV exposure through controlled airflow and shade, preserving fruit quality and reducing nutrient breakdown during dehydration.

Moisture gradient mapping

Sun drying exposes fruit to uneven airflow and temperature fluctuations, resulting in inconsistent moisture gradient mapping and potential spoilage due to prolonged drying times. Solar dehydrators create controlled environments with uniform heat distribution, enhancing precise moisture gradient control and improving dehydration efficiency and fruit quality.

Sun drying vs Solar dehydrator for fruit dehydration Infographic

cookingdiff.com

cookingdiff.com