Stainless steel trays offer superior durability and resistance to corrosion compared to plastic trays, making them ideal for long-term use in dehydrating pets' treats. Plastic trays, while lightweight and often more affordable, may retain odors and are prone to cracking or warping under heat. Choosing stainless steel trays ensures safer, cleaner dehydration processes and enhanced product longevity.

Table of Comparison

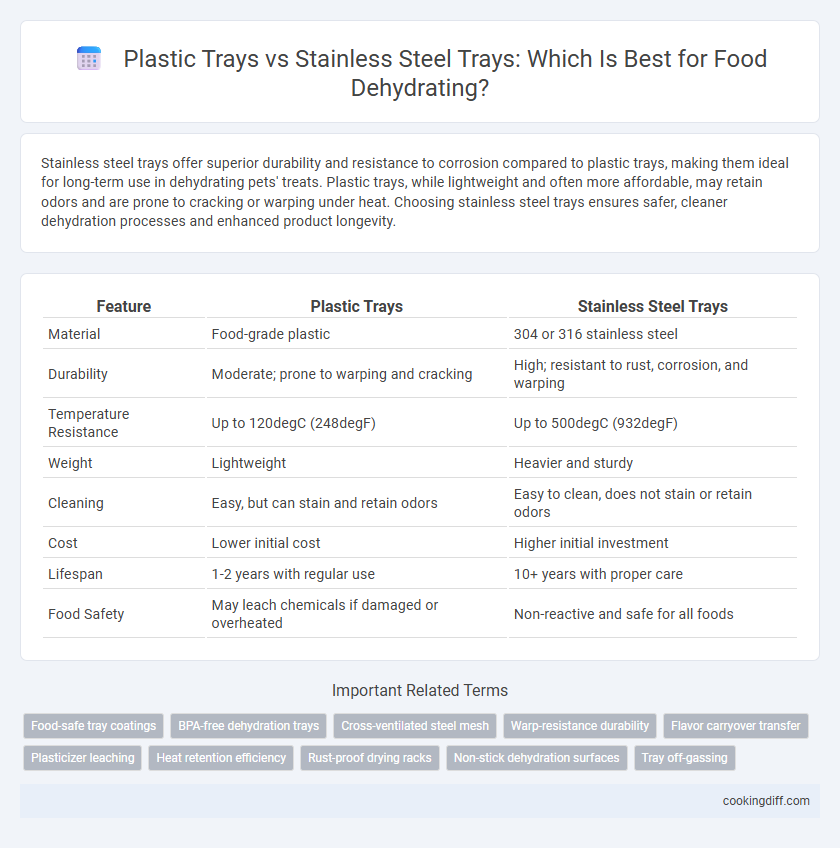

| Feature | Plastic Trays | Stainless Steel Trays |

|---|---|---|

| Material | Food-grade plastic | 304 or 316 stainless steel |

| Durability | Moderate; prone to warping and cracking | High; resistant to rust, corrosion, and warping |

| Temperature Resistance | Up to 120degC (248degF) | Up to 500degC (932degF) |

| Weight | Lightweight | Heavier and sturdy |

| Cleaning | Easy, but can stain and retain odors | Easy to clean, does not stain or retain odors |

| Cost | Lower initial cost | Higher initial investment |

| Lifespan | 1-2 years with regular use | 10+ years with proper care |

| Food Safety | May leach chemicals if damaged or overheated | Non-reactive and safe for all foods |

Introduction to Dehydrating: Why Tray Material Matters

What impact does tray material have on the dehydrating process? Plastic trays offer lightweight and corrosion-resistant benefits, but stainless steel trays provide superior durability and heat conductivity for even drying. Choosing the right tray material directly influences dehydration efficiency and food safety.

Overview: Plastic vs Stainless Steel Trays

Plastic trays are lightweight and often more affordable, but they may retain odors and are prone to warping at high temperatures during dehydration. Stainless steel trays offer superior durability, heat resistance, and are easier to sanitize, making them ideal for long-term use in dehydrating foods.

- Plastic trays - Made from lightweight materials that can absorb odors and may degrade under prolonged heat exposure.

- Stainless steel trays - Highly durable, resistant to corrosion, and maintain structural integrity under high temperatures.

- Sanitation and maintenance - Stainless steel is easier to clean and less likely to harbor bacteria compared to plastic trays.

Heat Distribution and Efficiency

Stainless steel trays offer superior heat distribution due to their conductive properties, resulting in more efficient and even dehydrating processes compared to plastic trays. Plastic trays often exhibit uneven heating and longer drying times due to their lower thermal conductivity.

- Heat Conductivity of Stainless Steel - Stainless steel's high thermal conductivity ensures consistent temperature across the tray surface, improving dehydration uniformity.

- Plastic Tray Insulation - Plastic trays act as insulators, causing hotspots and cooler areas that hinder efficient dehydration.

- Energy Efficiency - Stainless steel trays reduce energy consumption by decreasing dehydration time through effective heat transfer.

Food Safety and Material Reactivity

Plastic trays used for dehydrating are typically BPA-free and food-grade, minimizing the risk of harmful chemical leaching during low-temperature drying processes. However, some plastics may degrade or release toxins if exposed to higher temperatures or prolonged use, raising food safety concerns.

Stainless steel trays offer superior food safety by being non-reactive and resistant to corrosion, preventing contamination during dehydration. Their durable surface does not absorb odors or flavors, ensuring hygienic and safe drying of various foods over time.

Durability and Longevity

Stainless steel trays offer superior durability and resistance to wear compared to plastic trays, making them ideal for frequent dehydrating use. Plastic trays may degrade or warp over time when exposed to heat and repeated cleaning, reducing their lifespan.

- Corrosion Resistance - Stainless steel resists corrosion, maintaining integrity even after extended exposure to moisture and heat.

- Impact Durability - Plastic trays are more prone to cracking or breaking under heavy use, while stainless steel withstands physical impact better.

- Long-Term Value - Stainless steel trays provide longer service life, offering better cost efficiency over multiple dehydration cycles.

Choosing stainless steel trays enhances durability and longevity for consistent, high-quality dehydrating results.

Cleaning and Maintenance Comparisons

Plastic trays for dehydrating are lightweight and resistant to corrosion but can harbor stains and odors, requiring frequent deep cleaning with mild detergents. Stainless steel trays offer superior durability and ease of maintenance, as they do not absorb food particles and can be thoroughly cleaned with harsh sanitizers without damage. While stainless steel trays tend to be more expensive initially, their long-term hygiene benefits and reduced maintenance efforts make them a preferred choice for efficient dehydrating processes.

Flavor Preservation and Odor Retention

Stainless steel trays excel in flavor preservation during dehydrating due to their non-porous surface, which prevents absorption of food odors and flavors. Plastic trays, especially those made from lower-quality materials, can retain residual odors and transfer unwanted flavors between batches. Choosing stainless steel trays minimizes cross-contamination and ensures cleaner, more consistent taste outcomes in dried foods.

Environmental Impact and Sustainability

Plastic trays for dehydrating typically have a lower initial carbon footprint due to less energy-intensive production processes compared to stainless steel trays. However, plastic durability is limited, often resulting in more frequent replacements and increased plastic waste in landfills.

Stainless steel trays, though energy-intensive to produce, offer unmatched longevity and recyclability, significantly reducing environmental impact over their lifespan. Their sustainable nature supports circular economy principles by minimizing waste and resource consumption in food dehydration practices.

Cost Considerations: Upfront and Long-term

| Plastic Trays | Lower upfront cost, typically ranging from $10 to $30 per tray, making them budget-friendly for beginners or occasional users. However, plastic trays may require replacement every 1-2 years due to wear, leading to higher long-term expenses. They are less durable and prone to warping or cracking when exposed to heat frequently. |

| Stainless Steel Trays | Higher initial investment, generally between $50 to $100 per tray, but offer greater durability and resistance to heat and stains. Stainless steel trays can last many years with minimal maintenance, reducing long-term replacement costs significantly. Their robust design supports frequent use in commercial or heavy-duty dehydrating environments. |

Related Important Terms

Food-safe tray coatings

Plastic trays with food-safe coatings such as BPA-free polypropylene provide lightweight, affordable options for dehydrating, but may retain odors and stains over time. Stainless steel trays offer superior durability and non-reactive surfaces, ensuring hygienic dehydration without leaching harmful substances, making them ideal for long-term food safety.

BPA-free dehydration trays

BPA-free plastic trays offer a lightweight, affordable option for dehydrating with the benefit of chemical-free food safety, while stainless steel trays provide superior durability, resistance to corrosion, and ease of cleaning without leaching harmful substances. Choosing BPA-free trays ensures toxin-free dehydration, with stainless steel trays favored for long-term use due to their non-reactive surface and sustainability.

Cross-ventilated steel mesh

Cross-ventilated stainless steel mesh trays provide superior airflow and even drying during dehydration compared to plastic trays, which often trap moisture and hinder consistent dehydration. The open mesh design of stainless steel trays enhances heat circulation and prevents sogginess, ensuring faster and more efficient drying results.

Warp-resistance durability

Stainless steel trays offer superior warp-resistance durability compared to plastic trays, maintaining structural integrity under high heat and prolonged use during dehydrating. Plastic trays are more prone to warping and degradation, reducing their lifespan and effectiveness in consistent dehydration processes.

Flavor carryover transfer

Stainless steel trays resist flavor carryover during dehydrating due to their non-porous surfaces, preventing the absorption of odors from previously dried foods. Plastic trays, especially those with porous textures, can retain flavors and aromas, leading to potential cross-contamination and altered taste profiles in subsequent dehydrated products.

Plasticizer leaching

Plastic trays used for dehydrating may pose risks of plasticizer leaching, which can contaminate food with harmful chemicals such as phthalates. Stainless steel trays offer a safer alternative by providing a non-toxic, durable surface that prevents chemical migration during the dehydration process.

Heat retention efficiency

Stainless steel trays offer superior heat retention efficiency compared to plastic trays, ensuring more consistent and even drying temperatures during the dehydrating process. Plastic trays tend to have lower thermal conductivity, causing uneven heat distribution and longer dehydration times.

Rust-proof drying racks

Stainless steel trays offer superior rust-proof qualities compared to plastic trays, ensuring durability and hygiene during dehydration processes. Their non-corrosive surface maintains food safety and eliminates contamination risks associated with rust, making stainless steel the optimal choice for long-term use.

Non-stick dehydration surfaces

Plastic trays provide a naturally non-stick surface ideal for dehydrating sticky or delicate foods, reducing the need for additional oils or liners. Stainless steel trays, while durable and easy to clean, often require non-stick coatings or liners to prevent food from sticking during dehydration.

Plastic trays vs Stainless steel trays for dehydrating. Infographic

cookingdiff.com

cookingdiff.com