A blender is ideal for creating smooth, uniform purees that dehydrate evenly, making it perfect for preparing pet treats like fruit leathers or veggie pastes. Food processors excel at chopping and shredding larger quantities of ingredients into coarse pieces, which can speed up the dehydration process for items needing texture, such as meat or vegetable jerky. Choosing between a blender and a food processor depends on the desired consistency and type of pet treats you plan to prepare for dehydration.

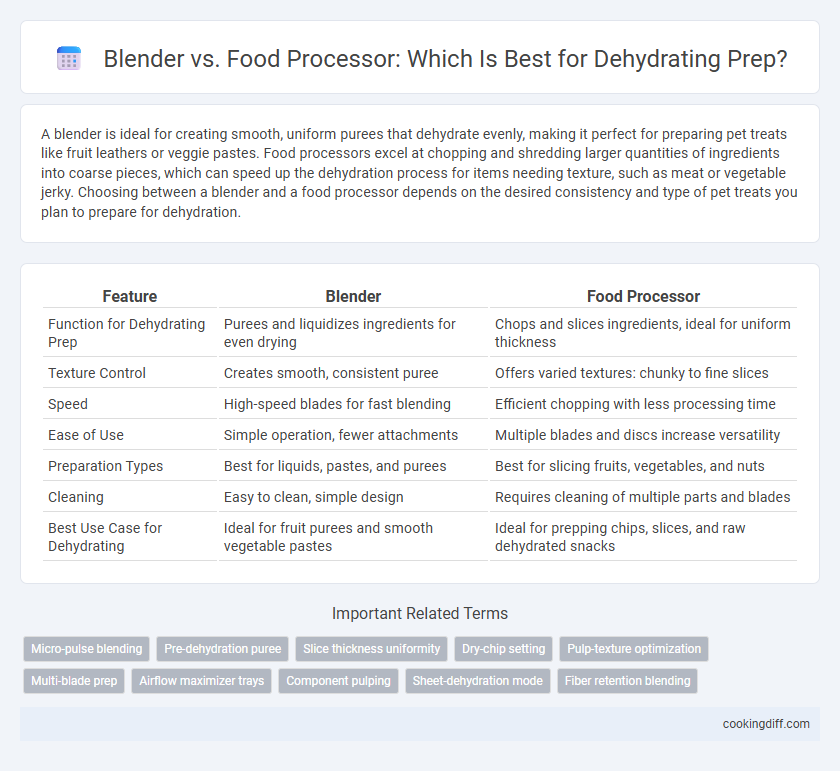

Table of Comparison

| Feature | Blender | Food Processor |

|---|---|---|

| Function for Dehydrating Prep | Purees and liquidizes ingredients for even drying | Chops and slices ingredients, ideal for uniform thickness |

| Texture Control | Creates smooth, consistent puree | Offers varied textures: chunky to fine slices |

| Speed | High-speed blades for fast blending | Efficient chopping with less processing time |

| Ease of Use | Simple operation, fewer attachments | Multiple blades and discs increase versatility |

| Preparation Types | Best for liquids, pastes, and purees | Best for slicing fruits, vegetables, and nuts |

| Cleaning | Easy to clean, simple design | Requires cleaning of multiple parts and blades |

| Best Use Case for Dehydrating | Ideal for fruit purees and smooth vegetable pastes | Ideal for prepping chips, slices, and raw dehydrated snacks |

Understanding Dehydrating Prep: Why Appliance Choice Matters

Choosing between a blender and a food processor significantly impacts dehydrating prep due to their differing blade designs and chopping consistency. Blenders create finer purees ideal for fruit leathers, while food processors provide chunkier textures suited for vegetable drying. Optimal dehydration results depend on matching the appliance to the specific texture requirements of the food being prepared.

Blender vs Food Processor: Key Functional Differences

Blenders and food processors serve different roles in dehydrating preparation, with blenders excelling at creating smooth purees and food processors better suited for chopping and slicing. Understanding their key functional differences helps optimize ingredient prep for dehydration.

- Blenders create uniform textures - They pulverize ingredients into smooth liquids ideal for making fruit leathers or purees before dehydrating.

- Food processors handle varied cutting tasks - Their sharp blades and multiple settings chop, shred, and slice produce uniformly to ensure consistent drying.

- Blenders have high-speed blades - Designed for liquid blending, they are less effective than food processors at processing solid, fibrous ingredients needed for dry prep.

Ingredient Preparation: Which Appliance Performs Best?

Blenders excel at liquefying ingredients, making them ideal for creating smooth purees necessary for dehydrating recipes like fruit leather or vegetable pastes. Their high-speed blades efficiently break down fibrous materials, ensuring even texture and moisture distribution during dehydration.

Food processors outperform blenders when chopping and slicing ingredients into uniform pieces, which improves dehydration rates and consistency for snacks like kale chips or vegetable crisps. Their adjustable blade attachments offer versatility in ingredient preparation, optimizing the texture for faster and more effective drying.

Texture Control: Blenders Compared to Food Processors

Blenders offer finer texture control for dehydrating prep by pureeing ingredients into smooth, consistent blends, ideal for making thin fruit leathers or nut butters. Food processors provide coarser, chunkier textures useful for prepping vegetable chips or salsa before drying. Choosing between them depends on whether a finely blended puree or a chunky mix is desired for optimum dehydration results.

Handling Fruits and Vegetables: Efficiency and Results

| Blender Efficiency | Blenders pulverize fruits and vegetables into smooth purees, enabling faster dehydration but often requiring additional spreading time for even drying. |

| Food Processor Efficiency | Food processors chop fruits and vegetables into uniform pieces, preserving texture and allowing more consistent dehydration with less preparation time. |

| Handling Results | Blenders create finer mixtures suitable for fruit leathers, while food processors retain chunkier textures ideal for vegetable chips and dried fruit slices. |

Leafy Greens and Herbs: Appliance Suitability for Dehydration

Blenders, designed for liquid blending, are less suitable for dehydrating leafy greens and herbs as they often create a puree rather than evenly chopped pieces needed for efficient drying. Food processors excel by uniformly chopping herbs and leafy greens into consistent sizes, enhancing dehydration speed and quality.

The precise chopping capability of food processors prevents moisture retention and promotes faster, even dehydration crucial for preserving nutrients in leafy greens. Using a food processor minimizes drying time and improves texture, which is essential for successful preservation of herbs and greens during dehydration.

Batch Size and Consistency: Blender vs Food Processor

Blenders excel in processing smaller batch sizes with smooth, consistent textures ideal for dehydrating purees or sauces. Food processors handle larger volumes efficiently, providing coarser textures suitable for vegetable chips and fruit slices.

Batch size significantly influences the choice between a blender and food processor in dehydrating preparation. Blenders offer precision for small, uniform blends, making them perfect for delicate ingredients requiring even dehydration. Food processors are better suited for bulk processing with consistent chopping and slicing, enhancing airflow and drying efficiency during dehydration.

Cleaning and Maintenance: Which is More Convenient?

Blenders often have fewer detachable parts, making them quicker and easier to clean after preparing ingredients for dehydration. Food processors feature multiple blades and components that require thorough cleaning to prevent residue buildup and maintain optimal performance.

- Blender's simple design - typically involves just a jar and blade assembly which can be rinsed or run through the dishwasher easily.

- Food processor's complex parts - include various blades and disks that demand careful handling and hand washing to avoid damage.

- Maintenance frequency - food processors may require more regular deep cleaning to ensure hygienic preparation for dehydrating tasks.

Cost Efficiency and Kitchen Space: Making the Right Choice

Choosing between a blender and a food processor for dehydrating prep hinges on cost efficiency and kitchen space. Blenders generally cost less and occupy less counter space, making them ideal for small kitchens.

- Blenders are more affordable - Entry-level blenders typically cost 20-30% less than mid-range food processors, reducing initial investment.

- Food processors offer multifunctionality - Though pricier, they can chop, slice, and shred, which may reduce the need for additional appliances.

- Kitchen space matters - Blenders have a more compact footprint, ideal for small or limited kitchen areas compared to bulkier food processors.

Considering both cost and space, blenders are often the more practical choice for dehydrating preparation in tight kitchens.

Related Important Terms

Micro-pulse blending

Micro-pulse blending in a blender offers precise control and smaller particle size ideal for dehydrating prep by creating uniform textures that promote faster, even drying. Food processors, while powerful, lack the finesse of micro-pulse technology, often producing uneven cuts that can slow dehydration and affect final product quality.

Pre-dehydration puree

Blenders create smoother, more uniform purees ideal for even dehydration, ensuring consistent texture and moisture levels that speed up drying times. Food processors produce chunkier purees with varied particle sizes, which can lead to uneven dehydration and longer drying periods.

Slice thickness uniformity

Blenders typically produce inconsistent slice thickness due to their blade design, making them less ideal for preparing uniform slices for dehydration. Food processors equipped with adjustable slicing discs offer precise control over slice thickness, ensuring even drying and better texture in dehydrated foods.

Dry-chip setting

Blenders with a dry-chip setting efficiently pulverize ingredients into uniform, fine particles ideal for dehydration, enhancing surface area and drying speed. Food processors, while versatile, often produce coarser, uneven textures that may lengthen drying time and affect consistency in dehydrated snacks.

Pulp-texture optimization

Blenders create a smoother pulp texture ideal for even dehydration and consistent drying times, while food processors produce coarser pulp that may require longer drying and result in uneven moisture retention. Optimizing pulp texture with a blender enhances dehydration efficiency and improves the final product's shelf life and quality.

Multi-blade prep

A blender with multi-blade prep capabilities efficiently pulverizes ingredients into smooth purees, ideal for evenly textured mixtures before dehydration. In contrast, a food processor's multi-blade design excels at chopping and shredding, producing thicker, more textured prep suitable for dehydrated snacks like fruit leather and vegetable chips.

Airflow maximizer trays

Airflow maximizer trays in blenders enhance dehydration prep by evenly circulating air, speeding moisture removal and improving drying consistency compared to food processors, which lack specialized airflow features that optimize dehydration efficiency. These trays allow blenders to maintain better temperature control and air distribution, crucial for uniform drying of fruits and vegetables during dehydration.

Component pulping

Blenders excel at component pulping for dehydrating prep by creating smoother, more uniform purees, which ensures even dehydration and consistent texture. Food processors, while effective at chopping, typically produce coarser pulps, potentially leading to uneven drying and varied moisture retention in dehydrated components.

Sheet-dehydration mode

Blenders with sheet-dehydration mode offer precise control over puree thickness, ensuring uniform drying and preventing uneven moisture retention, which is crucial for consistent dehydrated sheets. Food processors lack this specialized mode, making them less efficient for preparing thin, evenly dehydrated sheets due to inconsistent texture and thickness.

Blender vs Food processor for dehydrating prep. Infographic

cookingdiff.com

cookingdiff.com