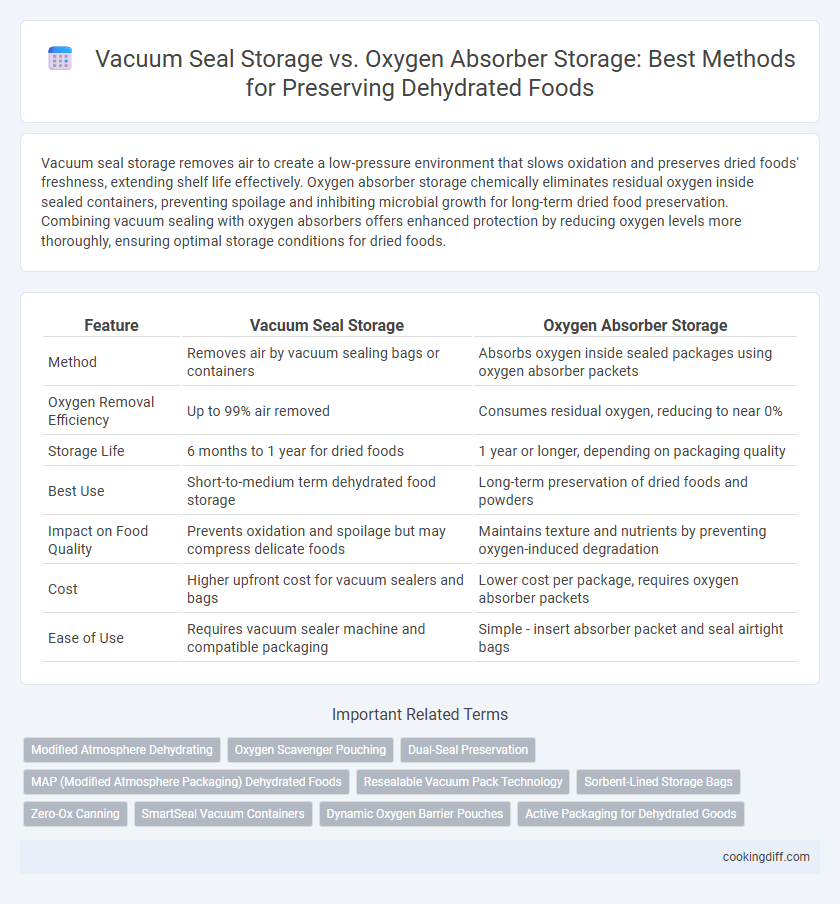

Vacuum seal storage removes air to create a low-pressure environment that slows oxidation and preserves dried foods' freshness, extending shelf life effectively. Oxygen absorber storage chemically eliminates residual oxygen inside sealed containers, preventing spoilage and inhibiting microbial growth for long-term dried food preservation. Combining vacuum sealing with oxygen absorbers offers enhanced protection by reducing oxygen levels more thoroughly, ensuring optimal storage conditions for dried foods.

Table of Comparison

| Feature | Vacuum Seal Storage | Oxygen Absorber Storage |

|---|---|---|

| Method | Removes air by vacuum sealing bags or containers | Absorbs oxygen inside sealed packages using oxygen absorber packets |

| Oxygen Removal Efficiency | Up to 99% air removed | Consumes residual oxygen, reducing to near 0% |

| Storage Life | 6 months to 1 year for dried foods | 1 year or longer, depending on packaging quality |

| Best Use | Short-to-medium term dehydrated food storage | Long-term preservation of dried foods and powders |

| Impact on Food Quality | Prevents oxidation and spoilage but may compress delicate foods | Maintains texture and nutrients by preventing oxygen-induced degradation |

| Cost | Higher upfront cost for vacuum sealers and bags | Lower cost per package, requires oxygen absorber packets |

| Ease of Use | Requires vacuum sealer machine and compatible packaging | Simple - insert absorber packet and seal airtight bags |

Introduction to Dried Food Storage Methods

| Vacuum seal storage for dried foods removes air to significantly reduce oxidation and microbial growth, extending shelf life up to several years. Oxygen absorber storage utilizes iron powder packets that chemically bind residual oxygen, preventing spoilage and preserving nutritional quality and color. Both methods are effective for maintaining dried foods, but vacuum sealing is ideal for immediate airtight sealing while oxygen absorbers are more suitable for long-term bulk storage in breathable packaging. |

How Vacuum Seal Storage Works

Vacuum seal storage removes air from the packaging, creating a low-oxygen environment that slows oxidation and microbial growth in dried foods. This process helps preserve texture, flavor, and nutritional value by minimizing exposure to moisture and contaminants.

The vacuum sealing machine extracts the air before securely sealing the bag with a heat strip, ensuring an airtight barrier. Compared to oxygen absorber storage, vacuum sealing offers immediate and consistent air removal, extending shelf life more effectively for dehydrated products.

Understanding Oxygen Absorber Storage

Oxygen absorber storage uses packets containing iron powder that chemically bind with oxygen, effectively eliminating it from sealed containers. This method significantly slows oxidation, preserving the color, flavor, and nutritional value of dried foods longer than vacuum sealing alone.

Unlike vacuum seal storage, which removes air mechanically, oxygen absorbers chemically reduce oxygen levels, reaching near-zero concentrations that inhibit aerobic microbial growth and spoilage. These absorbers are especially effective for long-term storage of dried fruits, grains, and jerky by maintaining product freshness. Proper use involves sealing foods in oxygen-impermeable bags or containers with the correct amount of absorbers based on container size and food type.

Key Benefits of Vacuum Sealing Dried Foods

Vacuum seal storage removes air, significantly reducing oxidation and extending the shelf life of dried foods up to 5 times longer than traditional storage methods. By eliminating moisture and oxygen, vacuum sealing preserves flavor, texture, and nutritional value more effectively than oxygen absorber packets alone. This method also prevents freezer burn and inhibits the growth of aerobic bacteria, molds, and yeasts, ensuring optimal food quality.

Advantages of Using Oxygen Absorbers

Oxygen absorbers extend the shelf life of dried foods by effectively removing oxygen, which prevents spoilage and oxidation. This method preserves color, flavor, and nutritional value better than vacuum seal storage, especially for long-term storage.

They also inhibit the growth of aerobic bacteria and molds, ensuring food safety and quality. Oxygen absorbers are cost-effective and easy to use, making them ideal for both small-scale and commercial dehydrated food storage.

Shelf Life Comparison: Vacuum Seal vs Oxygen Absorber

Vacuum seal storage and oxygen absorbers both significantly extend the shelf life of dried foods by minimizing oxygen exposure, but the effectiveness varies depending on the food type and storage conditions. Oxygen absorbers generally provide a longer shelf life, especially for foods with low moisture content, by actively removing residual oxygen inside sealed packaging.

- Vacuum Seal Storage - Reduces air volume around food, slowing oxidation and microbial growth but may leave some residual oxygen.

- Oxygen Absorber Storage - Chemically removes oxygen, creating an anaerobic environment that enhances preservation of dried foods.

- Shelf Life Comparison - Oxygen absorbers can extend shelf life up to 20-30% longer than vacuum sealing alone for many dehydrated products.

Choosing between vacuum seal and oxygen absorber storage depends on cost, packaging type, and specific food characteristics.

Impact on Food Quality and Freshness

Vacuum seal storage removes air to inhibit aerobic microbial growth, preserving dried food quality by maintaining texture and flavor. Oxygen absorber storage chemically binds residual oxygen, extending shelf life and preventing oxidation-related spoilage.

- Vacuum Seal Efficiency - Creates an airtight environment that slows moisture absorption and microbial proliferation, crucial for dried food preservation.

- Oxygen Absorber Functionality - Eliminates trace oxygen, reducing oxidative damage and maintaining color and nutrient stability in dried foods.

- Impact on Freshness - Both methods significantly enhance freshness, but oxygen absorbers provide superior protection against oxidation compared to vacuum sealing alone.

Cost and Accessibility of Storage Supplies

Vacuum seal storage generally requires specialized equipment such as a vacuum sealer and custom bags, which may have a higher upfront cost and limited accessibility in some areas. Oxygen absorber storage uses inexpensive packets that are widely available and easy to use but may require additional airtight containers for optimal preservation.

- Higher initial cost for vacuum sealers - Vacuum sealing systems can be costly initially compared to purchasing oxygen absorbers alone.

- Wider availability of oxygen absorbers - Oxygen absorber packets are commonly sold online and in stores, making them more accessible for most users.

- Accessory needs for oxygen absorber storage - To maximize shelf life, oxygen absorbers typically need to be combined with airtight containers, adding a minor extra expense.

Best Practices for Long-Term Storage of Dehydrated Foods

Vacuum seal storage removes air to prevent oxidation and moisture, significantly extending the shelf life of dehydrated foods. Oxygen absorber storage chemically binds residual oxygen, further reducing spoilage and preserving flavor and texture over long-term storage. Combining vacuum sealing with oxygen absorbers offers optimal protection against microbial growth and rancidity for dehydrated food preservation.

Related Important Terms

Modified Atmosphere Dehydrating

Vacuum seal storage reduces oxygen levels by physically removing air, which slows oxidation and microbial growth, while oxygen absorber storage chemically eliminates residual oxygen within the packaging, creating a more stable Modified Atmosphere Dehydrating environment. Utilizing oxygen absorbers in sealed bags optimizes shelf life and nutrient retention of dried foods by maintaining low oxygen concentrations crucial for preserving flavor and texture.

Oxygen Scavenger Pouching

Oxygen scavenger pouches effectively extend the shelf life of dehydrated foods by removing residual oxygen, preventing oxidation and microbial growth better than traditional vacuum seal storage. This technology ensures superior preservation quality, maintaining nutrients and flavor stability in dried food products during long-term storage.

Dual-Seal Preservation

Vacuum seal storage and oxygen absorber storage both extend the shelf life of dried foods by reducing oxygen exposure, but Dual-Seal Preservation combines vacuum sealing with oxygen absorbers to create an optimal anaerobic environment. This method significantly inhibits microbial growth and oxidation, preserving the texture, flavor, and nutritional value of dehydrated foods for extended periods.

MAP (Modified Atmosphere Packaging) Dehydrated Foods

Vacuum seal storage removes air to reduce oxidation and microbial growth, extending shelf life of dehydrated foods, while oxygen absorber storage actively scavenges residual oxygen, creating an ideal Modified Atmosphere Packaging (MAP) environment that further inhibits spoilage and nutrient loss. MAP techniques combining oxygen absorbers with vacuum sealing optimize preservation by maintaining low oxygen levels and moisture control, critical for maintaining the quality and safety of dehydrated foods over extended storage periods.

Resealable Vacuum Pack Technology

Resealable vacuum pack technology offers superior protection for dried foods by removing air and creating an airtight environment that prevents moisture and oxygen, key factors in spoilage, from degrading product quality. Compared to oxygen absorber storage, resealable vacuum packs allow multiple uses without compromising the vacuum seal, combining convenience with enhanced shelf life and freshness retention.

Sorbent-Lined Storage Bags

Sorbent-lined storage bags combine the benefits of vacuum sealing and oxygen absorber technology by actively capturing residual moisture and oxygen, extending the shelf life of dried foods more effectively than vacuum seal storage alone. These bags create an optimal low-oxygen, low-humidity environment that prevents spoilage, mold growth, and nutrient degradation in dehydrated foods.

Zero-Ox Canning

Zero-Ox Canning outperforms traditional vacuum seal storage by utilizing oxygen absorbers to eliminate residual oxygen, extending the shelf life and preserving the flavor and nutritional quality of dried foods more effectively. Unlike vacuum sealing, which may leave trace oxygen, Zero-Ox Canning creates an anaerobic environment that inhibits oxidation and microbial growth, ensuring superior food preservation.

SmartSeal Vacuum Containers

SmartSeal Vacuum Containers enhance shelf life by removing air and preventing moisture intrusion, making them ideal for dehydrated foods requiring long-term storage. Compared to oxygen absorbers, these containers offer a reusable, airtight solution that maintains food freshness without the risk of oxygen absorber failure or exposure.

Dynamic Oxygen Barrier Pouches

Dynamic Oxygen Barrier Pouches offer superior protection for dried foods by combining vacuum seal storage with advanced oxygen absorption, extending shelf life by minimizing oxidation and moisture exposure. These pouches adapt to fluctuating oxygen levels, ensuring optimal preservation compared to standard vacuum sealing or oxygen absorber methods alone.

Vacuum seal storage vs Oxygen absorber storage for dried foods Infographic

cookingdiff.com

cookingdiff.com