Stainless steel dehydrators offer superior durability and resistance to odors compared to plastic dehydrators, making them ideal for long-term use when dehydrating pet food. Plastic dehydrators may be more affordable but can absorb smells and are prone to cracking or warping over time. Choosing stainless steel ensures a safer, more hygienic environment for preserving your pet's treats.

Table of Comparison

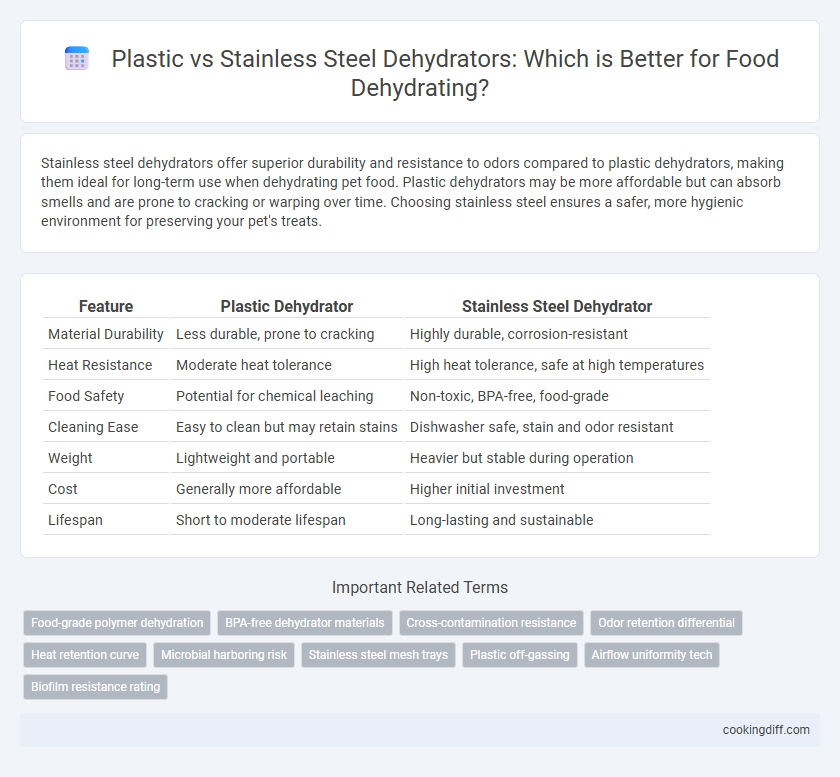

| Feature | Plastic Dehydrator | Stainless Steel Dehydrator |

|---|---|---|

| Material Durability | Less durable, prone to cracking | Highly durable, corrosion-resistant |

| Heat Resistance | Moderate heat tolerance | High heat tolerance, safe at high temperatures |

| Food Safety | Potential for chemical leaching | Non-toxic, BPA-free, food-grade |

| Cleaning Ease | Easy to clean but may retain stains | Dishwasher safe, stain and odor resistant |

| Weight | Lightweight and portable | Heavier but stable during operation |

| Cost | Generally more affordable | Higher initial investment |

| Lifespan | Short to moderate lifespan | Long-lasting and sustainable |

Introduction: Why Dehydrator Material Matters

What are the key differences between plastic dehydrators and stainless steel dehydrators when it comes to dehydrating? Plastic dehydrators are lightweight and often more affordable but may release harmful chemicals under high heat. Stainless steel dehydrators provide superior durability, temperature stability, and food safety, making them ideal for long-term dehydrating needs.

Overview of Plastic Dehydrators

Plastic dehydrators offer a lightweight and cost-effective solution for food dehydration, making them popular among beginners and casual users. Their clear trays allow easy monitoring of the drying process without opening the unit.

However, plastic materials may retain odors and stains more easily than stainless steel, and some lower-quality plastics could warp under high heat. Despite these drawbacks, plastic dehydrators are often valued for their affordability and ease of use.

Overview of Stainless Steel Dehydrators

Stainless steel dehydrators offer superior durability and corrosion resistance compared to plastic models, making them ideal for long-term use in food dehydration. Their non-porous surface ensures easy cleaning and prevents bacterial growth, enhancing food safety during the drying process.

These dehydrators provide consistent heat distribution due to their metal construction, resulting in even dehydration of fruits, vegetables, and meats. Stainless steel units often feature advanced temperature controls and sturdy racks, optimizing efficiency and user experience.

Durability: Plastic vs Stainless Steel

Plastic dehydrators are generally less durable due to susceptibility to cracking and warping under high heat. Stainless steel dehydrators offer superior durability with resistance to rust, corrosion, and physical damage.

- Plastic materials - Can degrade over time with frequent exposure to heat and moisture.

- Stainless steel construction - Provides long-term structural integrity and withstands daily use effectively.

- Maintenance - Stainless steel units are easier to clean and maintain without risk of damage compared to plastic.

Food Safety and Material Reactivity

Stainless steel dehydrators offer superior food safety due to their non-reactive, corrosion-resistant surface, which prevents contamination and maintains food purity during dehydration. Plastic dehydrators may pose risks of chemical leaching, especially at high temperatures, potentially compromising food safety and altering flavor.

- Non-reactive Material - Stainless steel does not react with acidic or alkaline foods, ensuring safe dehydration without chemical transfer.

- Chemical Leaching Risk - Plastic components can release harmful substances like BPA or phthalates when heated, affecting food quality.

- Durability and Cleanliness - Stainless steel is easier to sanitize and less prone to staining or odor retention compared to plastic.

Cleaning and Maintenance Comparison

Stainless steel dehydrators offer superior ease of cleaning due to their non-porous surface, which resists stains and odors better than plastic models. Plastic dehydrators may harbor bacteria and retain food odors over time, requiring more frequent and thorough cleaning to maintain hygiene. Stainless steel units also tend to be more durable under frequent cleaning, reducing maintenance efforts and costs in the long run.

Performance: Heat Distribution and Efficiency

Plastic dehydrators often provide uneven heat distribution due to their insulating properties, which can lead to inconsistent dehydration results. Stainless steel dehydrators excel in heat conduction, promoting uniform drying across all trays.

Stainless steel models offer superior energy efficiency by retaining and dispersing heat more effectively than plastic alternatives. This efficient heat distribution reduces drying time and preserves nutrient content in dehydrated foods. Plastic dehydrators may suffer from hotspots and longer dehydration cycles, impacting overall performance.

Price Differences: Upfront and Long-Term Costs

| Plastic Dehydrator | Stainless Steel Dehydrator |

|---|---|

| Generally lower upfront cost, making it accessible for beginners or budget-conscious users. Plastic models tend to have shorter lifespans, leading to higher replacement frequency and cumulative costs over time. | Higher initial investment due to durable materials and design, but offers superior longevity and resistance to wear, resulting in lower long-term expenses and maintenance needs. |

| Often less energy-efficient, which can increase operating costs during frequent use. Components may degrade faster, requiring more frequent repairs or part replacements. | Typically more energy-efficient with better heat distribution, reducing electricity consumption and operational costs over the appliance's lifespan. |

Environmental Impact and Sustainability

Stainless steel dehydrators offer a more sustainable choice due to their durability and recyclability, reducing long-term environmental waste compared to plastic alternatives. Plastic dehydrators often rely on non-biodegradable materials that contribute to landfill accumulation and resource depletion over time.

- Durability Advantage - Stainless steel units typically last longer, minimizing the frequency of replacement and waste generation.

- Recyclability - Stainless steel is more easily recycled, supporting circular economy efforts and reducing material waste.

- Plastic Environmental Cost - Production and disposal of plastic dehydrators involve toxic chemicals and microplastic pollution impacting ecosystems.

Choosing stainless steel over plastic enhances sustainability by lowering ecological footprints and supporting environmentally responsible consumption.

Related Important Terms

Food-grade polymer dehydration

Plastic dehydrators with food-grade polymer trays offer lightweight, non-reactive surfaces that resist corrosion and are easy to clean, making them suitable for safe, efficient dehydration of fruits and vegetables. Stainless steel dehydrators provide superior durability and heat retention but may be heavier and require more maintenance to prevent rust, making food-grade polymer models preferable for consistent, contamination-free drying.

BPA-free dehydrator materials

Stainless steel dehydrators offer a BPA-free alternative to plastic dehydrators, ensuring safer food dehydration by eliminating the risk of harmful chemical leaching. Their durable, non-toxic materials provide long-lasting performance ideal for drying fruits, vegetables, and meats without compromising food safety.

Cross-contamination resistance

Stainless steel dehydrators offer superior cross-contamination resistance due to their non-porous surfaces and ease of sterilization, reducing bacterial buildup compared to plastic models. Plastic dehydrators can absorb odors and stains, increasing the risk of cross-contamination during repeated use with different foods.

Odor retention differential

Plastic dehydrators tend to retain odors from previously dried foods due to their porous surfaces, which can affect the flavor of subsequent batches. Stainless steel dehydrators feature non-porous, smooth surfaces that resist odor absorption, ensuring cleaner drying cycles and more neutral-tasting results.

Heat retention curve

Plastic dehydrators typically exhibit lower heat retention due to their insulating properties, resulting in faster cooling once the heat source is removed, while stainless steel dehydrators maintain a more stable and consistent temperature over time because of their superior thermal conductivity and heat retention capacity. This heat retention curve difference directly impacts the dehydration efficiency and energy consumption, with stainless steel models often providing more uniform drying and reduced energy costs during prolonged use.

Microbial harboring risk

Plastic dehydrators pose a higher microbial harboring risk due to their porous surfaces that can trap bacteria and mold, especially in cracks and scratches; in contrast, stainless steel dehydrators offer a non-porous, smooth surface that is easier to clean and sterilize, significantly reducing contamination hazards during food dehydration. The antimicrobial benefits of stainless steel, combined with its durability and resistance to corrosion, make it a safer choice for preventing microbial growth and ensuring hygienic dehydration conditions.

Stainless steel mesh trays

Stainless steel mesh trays in dehydrators offer superior durability and resistance to rust compared to plastic trays, making them ideal for long-term use and high-temperature drying. Their fine mesh design allows for even airflow and efficient dehydration of fruits, vegetables, and herbs without risk of chemical leaching.

Plastic off-gassing

Plastic dehydrators often risk off-gassing harmful chemicals into food during the dehydration process, especially when exposed to high heat, compromising safety and flavor. Stainless steel dehydrators provide a non-toxic, durable alternative that resists off-gassing, ensuring cleaner, more natural dehydrating results.

Airflow uniformity tech

Plastic dehydrators often feature less advanced airflow uniformity technology, resulting in uneven drying and longer dehydration times. Stainless steel dehydrators utilize high-efficiency airflow systems that promote consistent heat distribution, ensuring faster and more uniform dehydration of foods.

Plastic dehydrator vs Stainless steel dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com