Using an oven for dehydrating pets can be effective but often lacks precise temperature control, increasing the risk of uneven drying or overcooking. Dehydrator drawers are specifically designed to maintain consistent low heat and airflow, ensuring safer and more efficient dehydration of pet treats. Choosing a dehydrator drawer helps preserve nutritional value and texture better than an oven.

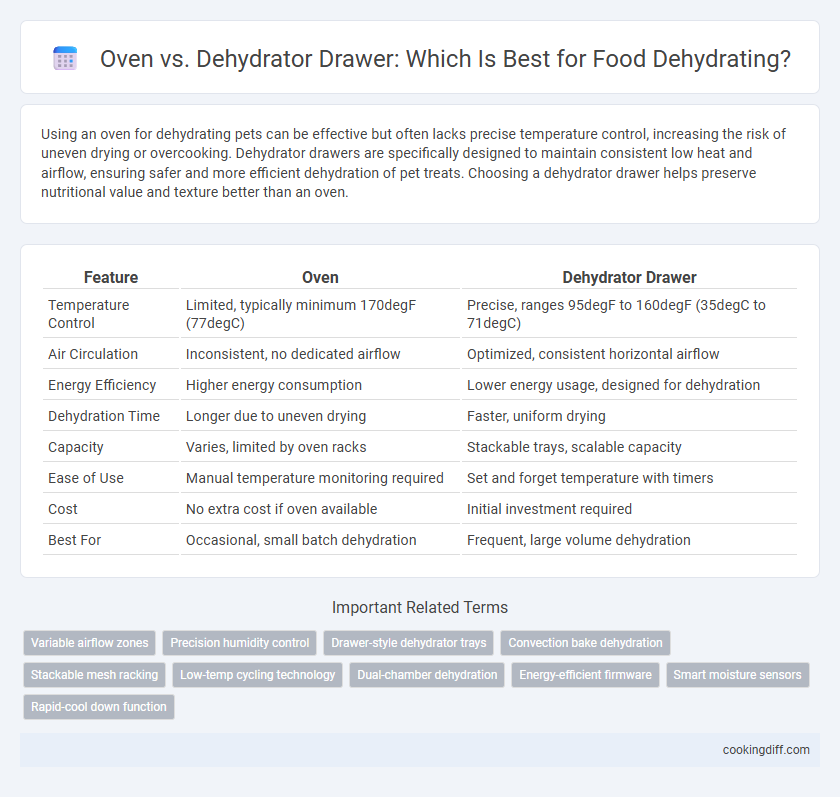

Table of Comparison

| Feature | Oven | Dehydrator Drawer |

|---|---|---|

| Temperature Control | Limited, typically minimum 170degF (77degC) | Precise, ranges 95degF to 160degF (35degC to 71degC) |

| Air Circulation | Inconsistent, no dedicated airflow | Optimized, consistent horizontal airflow |

| Energy Efficiency | Higher energy consumption | Lower energy usage, designed for dehydration |

| Dehydration Time | Longer due to uneven drying | Faster, uniform drying |

| Capacity | Varies, limited by oven racks | Stackable trays, scalable capacity |

| Ease of Use | Manual temperature monitoring required | Set and forget temperature with timers |

| Cost | No extra cost if oven available | Initial investment required |

| Best For | Occasional, small batch dehydration | Frequent, large volume dehydration |

Introduction to Dehydrating: Oven vs Dehydrator Drawer

Dehydrating food preserves nutrients by removing moisture, extending shelf life without refrigeration. Two popular methods are using a conventional oven or a specialized dehydrator drawer, each offering distinct advantages for drying various foods efficiently.

- Temperature Control - Dehydrator drawers provide precise low-temperature settings ideal for delicate herbs and fruits.

- Energy Efficiency - Dehydrators typically consume less energy over extended drying periods compared to ovens.

- Capacity and Airflow - Ovens offer larger space but may lack the consistent airflow of dehydrator drawers, affecting drying uniformity.

How Oven Dehydrating Works

How does oven dehydrating work compared to a dehydrator drawer? Oven dehydrating uses consistent low heat, usually between 120degF and 160degF, to remove moisture from food. Unlike dehydrator drawers that circulate air evenly, ovens rely on their heating element and slight air vents, which may require occasional door propping for airflow control.

How Dehydrator Drawer Systems Operate

Dehydrator drawer systems operate by circulating warm air uniformly across stacked trays, ensuring consistent moisture removal from foods. Each drawer functions as an independent drying chamber, allowing users to dehydrate different foods simultaneously at varying temperatures.

The airflow in dehydrator drawers is designed to maximize efficiency, using vents and fans to maintain even drying without hot spots. Unlike oven dehydration, which relies on ambient heat and may cause uneven drying, drawer systems optimize temperature control and airflow for superior results.

Energy Efficiency: Oven vs Dehydrator Drawer

Dehydrator drawers consume significantly less energy compared to conventional ovens, making them a more sustainable choice for drying foods. Ovens require more power to maintain low temperatures over extended periods, impacting energy bills and environmental footprint.

- Lower Wattage Use - Dehydrator drawers typically operate at 200-500 watts, whereas ovens can use 2000-5000 watts.

- Consistent Temperature Control - Dehydrator drawers maintain steady low heat more efficiently, preventing energy waste from temperature fluctuations common in ovens.

- Optimized Airflow System - Dehydrators feature built-in fans that circulate hot air efficiently, reducing drying time and energy consumption compared to passive oven airflow.

Choosing a dehydrator drawer over an oven for dehydrating ensures substantial energy savings and a lower carbon footprint.

Temperature Control and Consistency

Oven temperature control is often less precise compared to a dedicated dehydrator, leading to potential uneven drying. Dehydrator drawers are designed for consistent airflow and stable temperature, ensuring uniform dehydration.

Dehydrators maintain low, steady temperatures ideal for preserving nutrients and preventing cooking. Oven temperatures fluctuate and rarely stay as low as needed for effective dehydration. This inconsistency can result in uneven moisture removal and compromised food quality.

Drying Time Comparison

Dehydrators typically offer more consistent airflow and temperature control, resulting in shorter drying times compared to oven dehydrator drawers. Dehydrator drawers maintain lower temperatures around 130degF to 160degF, optimizing moisture removal without cooking the food. Oven dehydrator drawers often require longer drying periods due to less precise temperature regulation and uneven air distribution.

Food Quality and Flavor Retention

Oven dehydrating often results in uneven heat distribution, which can cause inconsistent moisture levels and potential nutrient loss in foods. Dehydrator drawers are specifically designed to maintain consistent low temperatures and airflow, preserving food quality more effectively.

Flavor retention is stronger in dehydrator drawers as the controlled environment minimizes oxidation and prevents burning. Oven drying can lead to altered taste profiles due to fluctuating temperatures and extended drying times.

Capacity and Batch Size Considerations

Oven dehydrating typically offers larger capacity compared to dehydrator drawers, allowing for bigger batch sizes and more efficient processing of large quantities. Dehydrator drawers are designed for more uniform airflow and temperature control, which can result in better dehydration quality but may limit batch size due to drawer dimensions. Selecting between an oven and a dehydrator drawer depends on balancing the need for volume with the importance of consistent drying conditions.

Ease of Use and Maintenance

Using a dehydrator drawer offers superior ease of use with precise temperature controls designed specifically for drying foods, minimizing the risk of uneven dehydration. Ovens require manual temperature monitoring and frequent adjustments, making maintenance and consistent results more challenging.

- Dehydrator drawer controls - Provide accurate temperature settings tailored for different food types ensuring efficient dehydration.

- Oven temperature variability - Demands constant supervision to prevent over-drying or under-drying.

- Cleaning ease - Dehydrator trays are typically dishwasher safe, simplifying routine cleaning compared to oven racks.

Related Important Terms

Variable airflow zones

Oven drying often has uneven heat distribution and lacks precise airflow control, resulting in inconsistent dehydration across different zones. Dehydrator drawers feature variable airflow zones that ensure uniform drying by directing consistent, adjustable air circulation for optimal moisture removal.

Precision humidity control

Oven drying lacks precision humidity control, often resulting in uneven moisture removal and potential overheating that compromises food quality. Dehydrator drawers offer accurate humidity regulation, maintaining optimal drying conditions for consistent texture and nutrient retention.

Drawer-style dehydrator trays

Drawer-style dehydrator trays provide evenly spaced airflow and consistent temperature distribution, optimizing moisture removal from fruits, vegetables, and herbs. Unlike ovens, these trays prevent uneven drying and allow for better preservation of nutrients and flavor during the dehydration process.

Convection bake dehydration

Convection bake dehydration in an oven provides consistent heat circulation that efficiently removes moisture from foods, though it may consume more energy compared to a dedicated dehydrator drawer designed for optimal airflow and low-temperature control. Dehydrators typically maintain precise humidity and temperature settings crucial for preserving nutritional quality and texture, whereas ovens with convection bake settings often risk uneven drying or overcooking due to less specialized airflow management.

Stackable mesh racking

Stackable mesh racks in dehydrator drawers provide optimal airflow and even drying by allowing moisture to escape efficiently from all sides of the food, unlike traditional ovens where heat distribution can be uneven and airflow limited. These racks also maximize space by enabling multiple layers of food to dehydrate simultaneously without overlapping, resulting in consistent texture and reduced drying times.

Low-temp cycling technology

Oven dehydrating often lacks low-temp cycling technology, leading to uneven drying and potential nutrient loss, whereas dehydrator drawers utilize precise temperature controls and airflow to maintain consistent low temperatures ideal for preserving food quality. This technology ensures efficient moisture removal while preventing overheating, making dehydrator drawers superior for delicate drying processes.

Dual-chamber dehydration

Dual-chamber dehydration systems combine the consistent heat distribution of an oven with the air circulation efficiency of a dehydrator drawer, optimizing moisture removal and preserving nutrient content. This integration allows precise temperature control and enhanced airflow, resulting in faster drying times and improved texture for a variety of foods.

Energy-efficient firmware

Energy-efficient firmware in dehydrator drawers optimizes temperature control and airflow for consistent drying while minimizing power consumption compared to conventional ovens. This advanced technology extends appliance lifespan and reduces electricity costs, making dehydrator drawers a more sustainable option for dehydration processes.

Smart moisture sensors

Ovens lack smart moisture sensors, leading to uneven dehydration and potential over-drying, while dehydrator drawers utilize advanced humidity control technology to maintain optimal moisture levels for consistent drying. By precisely regulating temperature and airflow, dehydrator drawers prevent nutrient loss and ensure food retains its texture and flavor throughout the dehydration process.

Oven vs dehydrator drawer for dehydrating. Infographic

cookingdiff.com

cookingdiff.com