Microwave drying uses electromagnetic waves to rapidly remove moisture from food, offering faster drying times and enhanced energy efficiency compared to traditional methods. Ultrasonic drying, on the other hand, employs high-frequency sound waves to create micro-cavities that facilitate moisture evaporation, resulting in improved texture and nutrient retention. Both techniques provide innovative approaches to dehydration, with microwave drying excelling in speed and ultrasonic drying enhancing product quality.

Table of Comparison

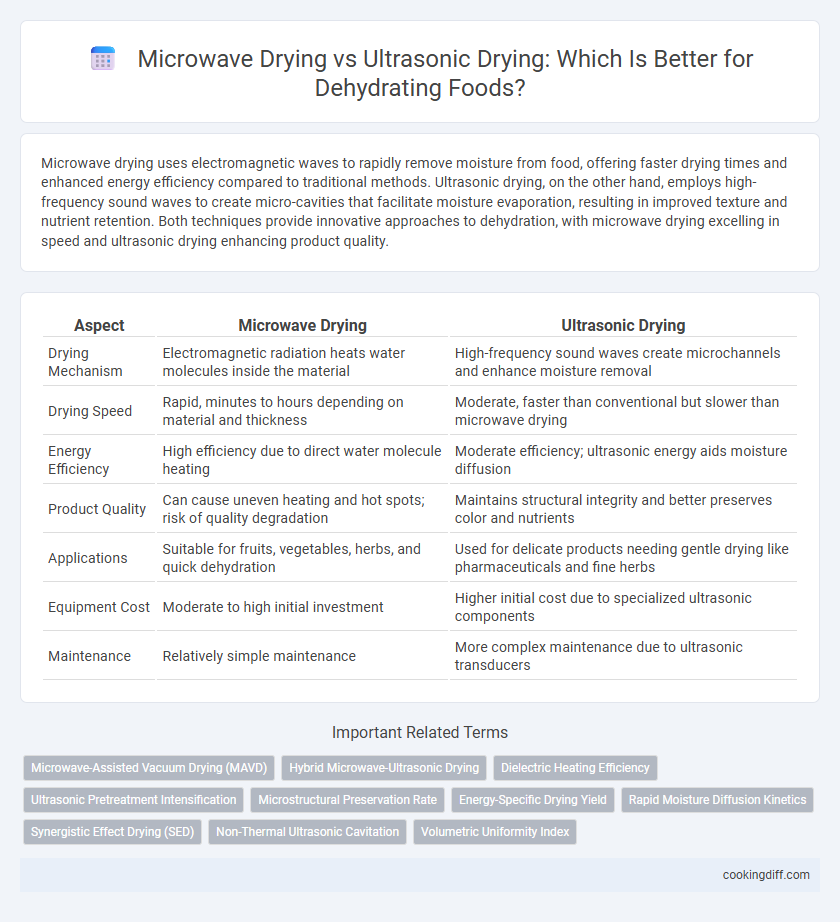

| Aspect | Microwave Drying | Ultrasonic Drying |

|---|---|---|

| Drying Mechanism | Electromagnetic radiation heats water molecules inside the material | High-frequency sound waves create microchannels and enhance moisture removal |

| Drying Speed | Rapid, minutes to hours depending on material and thickness | Moderate, faster than conventional but slower than microwave drying |

| Energy Efficiency | High efficiency due to direct water molecule heating | Moderate efficiency; ultrasonic energy aids moisture diffusion |

| Product Quality | Can cause uneven heating and hot spots; risk of quality degradation | Maintains structural integrity and better preserves color and nutrients |

| Applications | Suitable for fruits, vegetables, herbs, and quick dehydration | Used for delicate products needing gentle drying like pharmaceuticals and fine herbs |

| Equipment Cost | Moderate to high initial investment | Higher initial cost due to specialized ultrasonic components |

| Maintenance | Relatively simple maintenance | More complex maintenance due to ultrasonic transducers |

Overview of Microwave and Ultrasonic Drying Methods

| Drying Method | Principle | Advantages | Applications |

|---|---|---|---|

| Microwave Drying | Uses electromagnetic waves at microwave frequencies to produce heat internally, causing rapid moisture evaporation. | Fast drying rates, energy efficient, uniform heat distribution. | Food dehydration, pharmaceuticals, biomass drying. |

| Ultrasonic Drying | Employs high-frequency sound waves to create micro-vibrations, enhancing moisture removal through improved mass transfer. | Improves drying rate, preserves material quality, reduces drying temperature. | Heat-sensitive materials, delicate fruits, pharmaceuticals. |

Principles Behind Microwave Drying Technology

Microwave drying technology operates by generating electromagnetic waves that cause water molecules within the material to oscillate rapidly, producing internal heat and accelerating moisture evaporation. This method ensures uniform drying and minimizes thermal damage compared to conventional techniques. Unlike ultrasonic drying, which uses high-frequency sound waves to create cavitation and promote moisture removal, microwave drying relies on dielectric heating for efficient dehydration.

Fundamentals of Ultrasonic Drying Techniques

Ultrasonic drying employs high-frequency sound waves to create micro-vibrations that enhance moisture removal from materials, improving drying rates compared to conventional methods like microwave drying. These acoustic waves induce cavitation and agitation at the microscopic level, disrupting bound water molecules and facilitating faster dehydration.

This drying technique offers precise control over temperature and humidity, reducing thermal damage commonly associated with microwave drying. Ultrasonic drying is especially effective for heat-sensitive products as it maintains structural integrity while accelerating moisture loss. Its energy efficiency and uniform drying distribution make it a promising alternative in industrial dehydrating applications.

Key Differences Between Microwave and Ultrasonic Dehydration

Microwave drying uses electromagnetic waves to generate heat rapidly within the material, leading to faster moisture removal compared to ultrasonic drying, which employs high-frequency sound waves to induce cavitation and enhance water diffusion. The energy consumption and drying efficiency differ significantly as microwave drying tends to be more energy-intensive but quicker, whereas ultrasonic drying offers gentle processing ideal for heat-sensitive products.

- Mechanism - Microwave drying heats the product volumetrically through dielectric heating, while ultrasonic drying relies on acoustic cavitation to facilitate moisture release.

- Drying speed - Microwave drying generally achieves faster dehydration rates due to direct internal heating.

- Product quality - Ultrasonic drying preserves structural integrity better, reducing damage in delicate or heat-sensitive materials.

Efficiency and Speed Comparison: Microwave vs Ultrasonic Drying

Microwave drying offers significantly faster dehydration times due to volumetric heating, enhancing efficiency by rapidly removing moisture from the material. This method can reduce energy consumption compared to conventional drying techniques, making it suitable for industrial applications requiring speed.

Ultrasonic drying utilizes high-frequency vibrations to facilitate moisture removal, which improves drying uniformity but generally operates at slower rates than microwave drying. While ultrasonic drying provides gentler treatment ideal for delicate materials, its longer processing times limit its efficiency in high-throughput environments.

Impact on Food Texture and Quality

Microwave drying rapidly removes moisture while preserving the cellular structure of food, resulting in a better texture and maintaining nutritional quality. Ultrasonic drying uses high-frequency vibrations to enhance moisture removal without excessive heat, which helps retain color and flavor profiles.

- Microwave drying enhances retention of vitamins and antioxidants - It reduces drying time, minimizing thermal degradation.

- Ultrasonic drying improves porosity - This promotes uniform drying and prevents texture hardening.

- Both methods reduce shrinkage and surface hardening - Leading to improved rehydration properties in dehydrated products.

Choosing between these techniques depends on the desired balance between drying speed and preservation of sensory qualities in food.

Energy Consumption and Sustainability

Microwave drying consumes significantly less energy compared to ultrasonic drying, making it a more efficient method for large-scale dehydration processes. Ultrasonic drying, although effective in preserving product quality, generally requires higher power input, leading to increased energy consumption. Prioritizing microwave drying supports sustainability goals by reducing carbon footprint and operational costs in industrial applications.

Nutrient Retention in Dehydrated Foods

Microwave drying preserves nutrients more effectively by rapidly removing moisture and minimizing thermal degradation compared to ultrasonic drying. Ultrasonic drying uses sound waves to accelerate dehydration but may lead to greater nutrient loss due to longer exposure times and mechanical effects.

- Microwave drying enhances vitamin retention - The rapid evaporation process reduces exposure to heat, thereby preserving heat-sensitive vitamins like vitamin C and folate.

- Ultrasonic drying increases drying efficiency - Sound waves facilitate water removal but can induce structural damage affecting nutrient stability.

- Nutrient retention varies by food type - Microwave drying is generally better for leafy vegetables, while ultrasonic drying suits fibrous fruits with moderate nutrient loss.

Application Suitability: Best Uses for Each Method

Microwave drying is highly suitable for dehydrating fruits and vegetables due to its rapid moisture removal and energy efficiency, making it ideal for high-throughput food processing. Ultrasonic drying excels in sensitive materials like herbs and pharmaceuticals, where gentle dehydration preserves bioactive compounds and structural integrity.

Microwave drying is preferred in applications requiring uniform dehydration and quick cycle times, such as snack production and ready-to-eat meals. Ultrasonic drying is preferred for delicate products requiring minimal thermal damage, including botanical extracts and aroma-rich spices.

Related Important Terms

Microwave-Assisted Vacuum Drying (MAVD)

Microwave-Assisted Vacuum Drying (MAVD) significantly reduces drying time and preserves heat-sensitive nutrients better than traditional Ultrasonic drying by combining rapid microwave energy with low-pressure vacuum conditions. MAVD enhances moisture removal efficiency, maintains product texture and color, and reduces energy consumption, making it highly suitable for dehydrating heat-sensitive food products.

Hybrid Microwave-Ultrasonic Drying

Hybrid Microwave-Ultrasonic drying combines the rapid volumetric heating of microwave energy with the enhanced moisture removal efficiency of ultrasonic waves, resulting in faster dehydration rates and improved product quality compared to standalone microwave or ultrasonic drying. This method reduces drying time, preserves nutritional content, and minimizes thermal damage, making it highly suitable for heat-sensitive and high-moisture food products.

Dielectric Heating Efficiency

Microwave drying leverages dielectric heating by directly exciting water molecules, resulting in faster moisture removal and higher energy efficiency compared to ultrasonic drying, which relies primarily on mechanical vibrations and less on dielectric properties. The superior dielectric heating efficiency of microwave drying enhances uniform moisture reduction and preserves product quality during dehydration processes.

Ultrasonic Pretreatment Intensification

Ultrasonic pretreatment intensification enhances dehydration efficiency by creating microchannels that accelerate moisture migration, significantly reducing drying time compared to microwave drying. This method preserves product quality through uniform dehydration while minimizing thermal degradation, making it a superior technique for delicate food products.

Microstructural Preservation Rate

Microwave drying demonstrates a higher microstructural preservation rate due to rapid moisture removal that minimizes cellular damage, maintaining tissue integrity more effectively than ultrasonic drying. Ultrasonic drying, while beneficial for enhancing drying speed, often induces cavitation effects that can disrupt microstructure, resulting in lower preservation quality.

Energy-Specific Drying Yield

Microwave drying demonstrates a higher energy-specific drying yield compared to ultrasonic drying, efficiently converting energy into moisture removal with reduced drying time. Ultrasonic drying, while effective for delicate products, typically consumes more energy per unit of water removed, resulting in lower energy efficiency.

Rapid Moisture Diffusion Kinetics

Microwave drying accelerates moisture diffusion kinetics by generating heat volumetrically, resulting in rapid internal vapor pressure that promotes efficient water migration. Ultrasonic drying enhances moisture diffusion through acoustic cavitation and microstreaming effects, disrupting cell structures to facilitate faster liquid removal compared to conventional methods.

Synergistic Effect Drying (SED)

Microwave drying combined with ultrasonic drying enhances moisture removal efficiency by leveraging the Synergistic Effect Drying (SED), which accelerates dehydration through simultaneous thermal and mechanical energy application. This synergistic approach improves drying rates, preserves product quality, and reduces energy consumption compared to using either method alone.

Non-Thermal Ultrasonic Cavitation

Non-thermal ultrasonic cavitation in ultrasonic drying enhances moisture removal by generating microscopic bubbles that collapse and disrupt cellular structures without significant heat, preserving the quality and nutrients of dehydrated products. Compared to microwave drying, which relies on rapid thermal energy causing potential overheating and nutrient loss, ultrasonic drying offers uniform dehydration with minimal thermal degradation, making it ideal for sensitive food materials.

Microwave drying vs Ultrasonic drying for dehydrating. Infographic

cookingdiff.com

cookingdiff.com