A food processor quickly chops and slices ingredients but lacks precise temperature control and airflow for effective dehydration. Dehydrator boxes provide consistent low heat and proper air circulation, making them ideal for evenly drying pet food while preserving nutrients. Choosing a dehydrator ensures optimal texture and safety in homemade dehydrated pet treats.

Table of Comparison

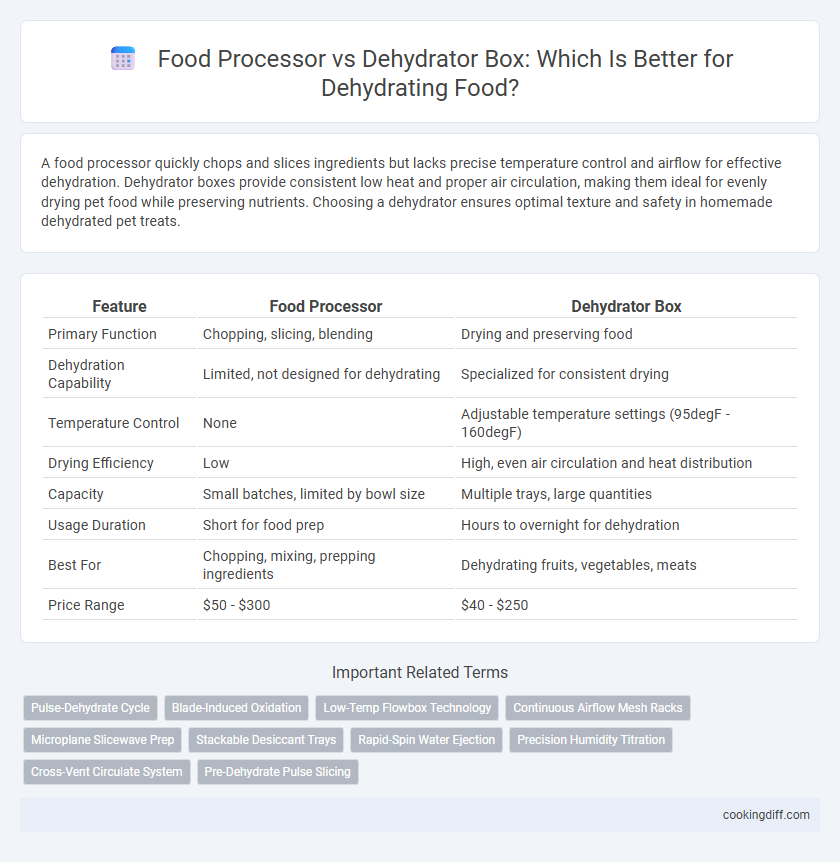

| Feature | Food Processor | Dehydrator Box |

|---|---|---|

| Primary Function | Chopping, slicing, blending | Drying and preserving food |

| Dehydration Capability | Limited, not designed for dehydrating | Specialized for consistent drying |

| Temperature Control | None | Adjustable temperature settings (95degF - 160degF) |

| Drying Efficiency | Low | High, even air circulation and heat distribution |

| Capacity | Small batches, limited by bowl size | Multiple trays, large quantities |

| Usage Duration | Short for food prep | Hours to overnight for dehydration |

| Best For | Chopping, mixing, prepping ingredients | Dehydrating fruits, vegetables, meats |

| Price Range | $50 - $300 | $40 - $250 |

Introduction: Comparing Food Processors and Dehydrator Boxes for Dehydrating

Food processors and dehydrator boxes serve distinct roles in the dehydrating process, with food processors primarily designed for chopping, slicing, and prepping food before drying. Dehydrator boxes provide controlled heat and airflow to effectively remove moisture, preserving food texture and nutrients. Selecting the appropriate appliance depends on whether the goal is food preparation or efficient moisture removal for long-term preservation.

How Food Processors Work in Food Dehydration

Food processors use high-speed blades to chop and puree foods, creating uniform pieces that dehydrate more evenly. By breaking down large chunks into smaller fragments, food processors help accelerate the dehydration process.

Unlike dehydrator boxes designed to circulate warm air consistently for drying, food processors do not remove moisture but prepare food for efficient dehydration. The chopped food spreads evenly on dehydrator trays, maximizing air exposure and reducing drying time. Combining these tools optimizes texture and preserves nutrients during dehydration.

How Dehydrator Boxes Operate for Drying Foods

| Dehydrator boxes operate by circulating warm air evenly around food items, effectively removing moisture without cooking them, preserving nutrients and flavor. This controlled airflow and temperature regulation create ideal conditions for drying a variety of foods such as fruits, vegetables, and meats. Unlike food processors, dehydrators use low heat over a longer period to achieve consistent dehydration results. |

Efficiency: Food Processor vs Dehydrator Box

Food processors excel in speed and uniform cutting, preparing fruits and vegetables quickly for dehydration. However, they do not remove moisture, requiring an additional step with a dehydrator box for actual drying.

Dehydrator boxes provide controlled low heat and airflow, ensuring even moisture removal crucial for preserving food quality and safety. Compared to food processors, dehydrators are more efficient in regulating drying time and preventing spoilage during dehydration.

Food Quality: Taste, Texture, and Nutritional Retention

Food processors can chop ingredients quickly but they do not dehydrate, often leading to uneven drying and compromised texture. Dehydrator boxes use controlled low heat and airflow to preserve optimal taste, texture, and nutritional value during the drying process.

- Taste Preservation - Dehydrator boxes maintain the natural flavors of food by using consistent temperatures that minimize flavor loss.

- Texture Control - Dehydrators ensure uniform moisture removal, resulting in crisp or chewy textures depending on the food type.

- Nutritional Retention - Low-temperature drying in dehydrator boxes helps retain vitamins and enzymes often destroyed by high heat in other methods.

Versatility: Uses Beyond Dehydrating

Food processors offer multifunctional capabilities such as chopping, slicing, and pureeing, making them versatile kitchen tools beyond just dehydrating tasks. In contrast, dehydrator boxes specialize in drying foods evenly and efficiently, with limited applications outside of dehydration.

- Food Processor Versatility - Can be used for preparing ingredients in various recipes, from smoothies to doughs.

- Dehydrator Specialization - Designed specifically for moisture removal to preserve fruits, vegetables, and meats.

- Utility Comparison - Food processors serve multiple culinary purposes, while dehydrators focus solely on drying processes.

Time and Energy Consumption

Which appliance is more efficient for dehydrating in terms of time and energy consumption? A food processor chops food quickly but does not remove moisture, requiring additional steps like oven drying that consume more energy and time. Dehydrator boxes are specifically designed to evenly remove moisture over extended periods, using less energy per batch and providing consistent drying results.

Ease of Use and Cleaning

Food processors offer quick preparation by slicing and chopping ingredients before dehydrating, but they require more assembly and cleaning. Dehydrator boxes simplify the drying process with dedicated trays and minimal cleanup, making them more user-friendly for dehydration tasks.

- Food Processors Demand More Cleanup - Multiple detachable blades and bowls need thorough washing after use.

- Dehydrator Boxes Feature Easy-to-Clean Trays - Removable trays typically allow for hassle-free rinsing or dishwasher cleaning.

- Dehydrator Boxes Provide Simplified Operation - One-button control and preset drying cycles reduce user effort.

Choosing a dehydrator box enhances ease of use and reduces cleaning time compared to a food processor for dehydration purposes.

Cost Comparison: Initial Investment and Ongoing Costs

Food processors generally have a lower initial investment, ranging from $50 to $200, while dehydrator boxes typically cost between $40 and $300 depending on size and features. However, food processors do not offer dedicated dehydration functions, which may require additional equipment for optimal drying results.

Ongoing costs for dehydrator boxes include electricity usage, which tends to be higher due to prolonged operation times, whereas food processors consume electricity only during short processing intervals. Maintenance costs for dehydrators involve occasional replacement of trays and heating elements, while food processors may require blade sharpening or replacement over time.

Related Important Terms

Pulse-Dehydrate Cycle

The pulse-dehydrate cycle in a food processor quickly alternates between chopping and airing, offering limited dehydration compared to a dedicated dehydrator box designed to maintain consistent low temperatures and airflow for even moisture removal. Dehydrator boxes provide precise temperature control and extended drying times, ensuring optimal preservation of texture and nutrients in foods.

Blade-Induced Oxidation

Food processors cause blade-induced oxidation by rapidly chopping food, which exposes more surface area to oxygen and accelerates nutrient degradation. Dehydrator boxes use low heat and airflow without mechanical disruption, preserving antioxidants and color by minimizing oxidative damage.

Low-Temp Flowbox Technology

Food processors lack the precise temperature control and airflow design found in dehydrator boxes equipped with Low-Temp Flowbox Technology, which ensures consistent drying by maintaining optimal low heat and even air circulation. This technology prevents nutrient loss and preserves texture better than conventional food processors, making dehydrator boxes superior for producing high-quality dehydrated foods.

Continuous Airflow Mesh Racks

Food dehydrators with continuous airflow mesh racks provide consistent heat distribution and optimized air circulation for efficient moisture removal, preserving flavor and nutrients more effectively than most food processors. Unlike food processors that rely on chopping or blending, dehydrators are specifically engineered for drying foods evenly over extended periods, ensuring superior texture and shelf-life.

Microplane Slicewave Prep

The Microplane Slicewave Prep offers precision slicing ideal for uniform dehydration, enhancing drying efficiency compared to generic food processors that lack specialized blade designs. Dehydrator boxes provide controlled low-temperature airflow essential for preserving nutrients and flavor, but pairing them with the Slicewave Prep maximizes speed and consistency in food preparation.

Stackable Desiccant Trays

Stackable desiccant trays in dehydrator boxes maximize airflow and even drying, making them ideal for efficient moisture removal compared to food processors, which lack this feature. Dehydrator trays offer controlled temperature settings and uniform drying, essential for preserving texture and nutrients during dehydration processes.

Rapid-Spin Water Ejection

Food processors excel in rapid-spin water ejection by using high-speed blades to remove moisture quickly from fruits and vegetables, significantly reducing initial water content before dehydration. Dehydrator boxes rely on controlled low heat and air circulation to gradually remove remaining moisture, ensuring evenly dried food with preserved nutrients and texture.

Precision Humidity Titration

Dehydrators offer precise humidity titration controls critical for consistent moisture removal, ensuring optimal texture and longevity in dried foods. Food processors lack this capability, making them less effective for achieving uniform dehydration and preventing spoilage.

Cross-Vent Circulate System

A food processor lacks the specialized Cross-Vent Circulate System found in dehydrator boxes, which ensures even airflow and consistent drying by circulating hot air around the food. This system prevents uneven moisture retention and reduces dehydration time, making dehydrator boxes more efficient for drying fruits, vegetables, and herbs.

Food processor vs Dehydrator box for dehydrating. Infographic

cookingdiff.com

cookingdiff.com