Using a jerky gun offers precise control over shape and thickness, resulting in uniform strips ideal for even drying, while a meat press compacts ground meat into larger slabs that require slicing before dehydrating. Jerky guns are preferred for homemade jerky due to their ease of use and ability to produce consistent pieces, enhancing texture and flavor absorption. Meat presses, on the other hand, are better suited for bulk preparation but may lead to less uniform drying and a different chewiness in the finished product.

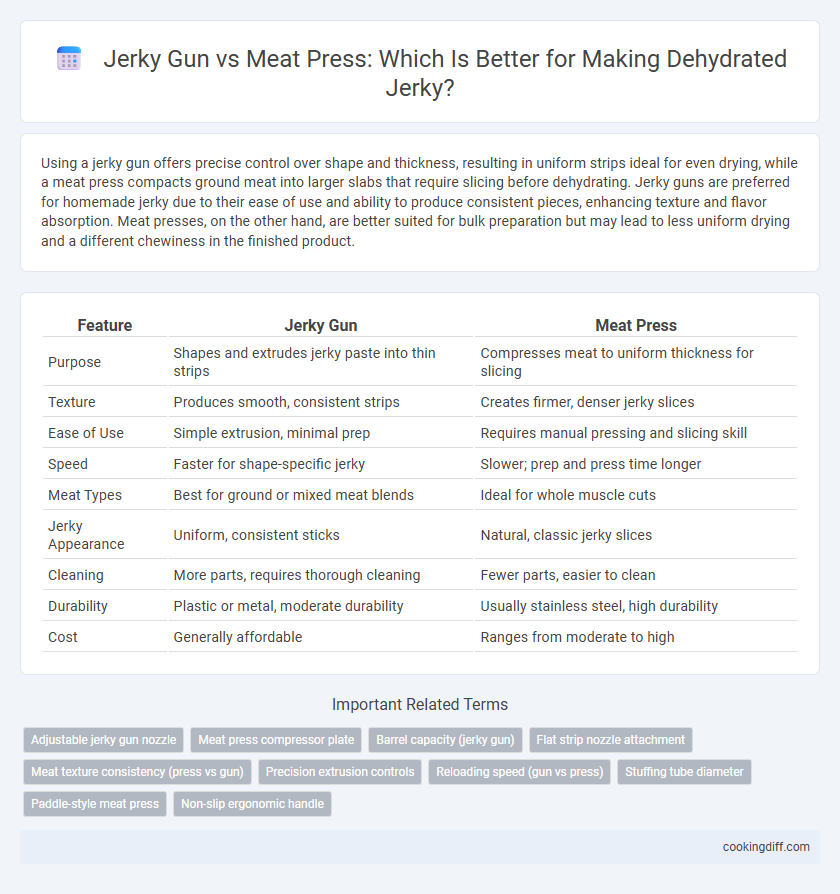

Table of Comparison

| Feature | Jerky Gun | Meat Press |

|---|---|---|

| Purpose | Shapes and extrudes jerky paste into thin strips | Compresses meat to uniform thickness for slicing |

| Texture | Produces smooth, consistent strips | Creates firmer, denser jerky slices |

| Ease of Use | Simple extrusion, minimal prep | Requires manual pressing and slicing skill |

| Speed | Faster for shape-specific jerky | Slower; prep and press time longer |

| Meat Types | Best for ground or mixed meat blends | Ideal for whole muscle cuts |

| Jerky Appearance | Uniform, consistent sticks | Natural, classic jerky slices |

| Cleaning | More parts, requires thorough cleaning | Fewer parts, easier to clean |

| Durability | Plastic or metal, moderate durability | Usually stainless steel, high durability |

| Cost | Generally affordable | Ranges from moderate to high |

Introduction: Choosing the Right Tool for Homemade Jerky

Jerky guns and meat presses are essential tools for preparing homemade jerky, each offering unique advantages. Jerky guns provide precise control over meat shape and thickness, ideal for consistent drying.

Meat presses excel in compacting ground meat to remove air pockets, promoting even dehydration and improved texture. Selecting the right tool influences the drying process, flavor retention, and overall jerky quality.

What is a Jerky Gun?

A jerky gun is a handheld device designed to extrude seasoned ground meat through various shaped nozzles, forming uniform strips or shapes for dehydrating into jerky. It streamlines the jerky-making process by creating consistent thickness and shape, ensuring even drying and better texture.

The jerky gun allows precise control over meat portions, reducing preparation time compared to traditional slicing methods. It works well for ground or minced meat blends, enabling the addition of spices and marinades directly into the mixture. This tool is favored for its efficiency and ability to produce professional-quality jerky with minimal effort.

What is a Meat Press?

A meat press is a kitchen tool used to shape and compress sliced meat into uniform strips before dehydrating. It ensures even thickness, which is essential for consistent drying and jerky quality.

- Purpose - Compacts meat slices to achieve a consistent thickness for uniform drying.

- Material - Typically made of stainless steel or heavy-duty plastic for durability and easy cleaning.

- Design - Features adjustable plates or clamps to press the meat firmly without damaging the texture.

Using a meat press helps improve jerky texture and reduces dehydration time by optimizing meat thickness.

Key Differences Between Jerky Guns and Meat Presses

Jerky guns and meat presses serve distinct roles in the jerky-making process, with jerky guns designed to extrude uniform strips of meat while meat presses compact ground meat into sheets for slicing. Both tools impact texture and preparation speed but differ significantly in their operation and output.

- Functionality - Jerky guns extrude meat in specific shapes, whereas meat presses form compact blocks of ground meat.

- Texture Outcome - Using a jerky gun produces consistent, thin strips; a meat press yields denser, thicker jerky pieces.

- Preparation Speed - Jerky guns allow faster shaping of individual sticks, while meat presses require additional slicing time after pressing.

Ease of Use: Jerky Gun vs Meat Press

The jerky gun offers superior ease of use with its ergonomic design, allowing for quick and uniform sausage-style jerky shaping directly onto dehydrator trays. In contrast, the meat press requires more manual effort and skill to evenly press and flatten meat sheets, making it less convenient for beginners. Users seeking efficiency and consistent results often prefer the jerky gun for hassle-free jerky preparation.

Output Quality: Texture and Shape Comparison

Jerky guns produce uniform, cylindrical strips that ensure consistent texture and even drying, ideal for maintaining a tender yet chewy bite. Meat presses yield irregular shapes with varying thickness, potentially causing uneven drying and a tougher, less desirable texture. Overall, the jerky gun offers superior control over jerky shape and texture, enhancing the final product's quality.

Capacity and Batch Size Considerations

Jerky guns offer lower capacity, ideal for small to medium batch sizes with consistent shapes. Meat presses accommodate larger quantities, making them suitable for high-volume jerky production.

- Jerky gun capacity - Typically processes a few pounds of meat at a time, perfect for home use or small batches.

- Meat press batch size - Enables pressing of larger slabs or multiple pieces simultaneously, increasing efficiency.

- Throughput comparison - Meat presses speed up preparation for bulk production compared to repeated jerky gun usage.

Cleaning and Maintenance Requirements

Which option requires less effort for cleaning and maintenance, the jerky gun or the meat press? Jerky guns typically have multiple small parts that need thorough cleaning to prevent bacteria buildup, making maintenance more time-consuming. Meat presses usually consist of fewer components and smoother surfaces, allowing for easier and faster cleaning between uses.

Best Use Cases for Jerky Guns and Meat Presses

| Jerky Gun | Ideal for creating thin, uniform strips of jerky with minimal effort; perfect for small to medium batches where precise portion control is desired. Allows for quick extrusion of ground meat or seasoned mixtures directly onto dehydrator trays or smokers. Best suited for users who prioritize speed, consistency, and ease of shaping jerky in home kitchens or small-scale production. |

| Meat Press | Designed to compact meat into dense, even slabs that can be thinly sliced after drying; optimal for larger batches and commercial-scale jerky production. Ensures tight, air-free texture aiding uniform dehydration and extended shelf life. Preferred by those seeking traditional jerky cuts and textures with enhanced moisture control and storage durability. |

Related Important Terms

Adjustable jerky gun nozzle

The adjustable jerky gun nozzle offers precise control over the thickness and shape of jerky strips, resulting in consistent dehydration and uniform drying times. Unlike meat presses, which rely on manual pressing and can cause uneven moisture distribution, jerky guns ensure optimal texture and efficient drying by extruding meat directly onto dehydrator trays.

Meat press compressor plate

A meat press compressor plate ensures even pressure distribution, removing excess moisture and promoting uniform dehydration for jerky. Compared to jerky guns, it offers consistent texture by compressing meat tightly, enhancing flavor retention and drying efficiency.

Barrel capacity (jerky gun)

A jerky gun typically features a barrel capacity ranging from 8 to 12 ounces, allowing for continuous and consistent extrusion of meat strips, which enhances efficiency during large-batch jerky production. In contrast, a meat press lacks a barrel component and requires manual slicing and pressing, making the jerky gun's barrel capacity a critical advantage for speeding up the dehydrating process.

Flat strip nozzle attachment

A jerky gun with a flat strip nozzle attachment produces uniform, evenly shaped strips ideal for consistent dehydration and drying, enhancing texture and flavor absorption. In contrast, a meat press lacks this precise shaping capability, often resulting in irregular thickness that can cause uneven drying and texture variation in jerky.

Meat texture consistency (press vs gun)

A jerky gun produces uniform strips of meat, resulting in a consistent thickness that promotes even dehydration and predictable texture. In contrast, a meat press compacts ground meat into denser blocks, which may lead to variable texture and uneven drying times due to thickness inconsistencies.

Precision extrusion controls

Jerky guns provide precise extrusion controls by allowing uniform thickness and consistent shape of meat strips, essential for even dehydration and optimal texture. Meat presses lack this level of control, often resulting in uneven jerky pieces that dehydrate inconsistently and affect flavor absorption.

Reloading speed (gun vs press)

Jerky guns offer faster reloading speeds compared to meat presses, enabling continuous and efficient jerky production by quickly refilling the cylinder with ground meat. Meat presses require more time for manual packing and shaping, which slows down the overall preparation process for making jerky.

Stuffing tube diameter

Jerky guns typically feature a smaller stuffing tube diameter, usually around 1 to 1.5 inches, allowing for more control and precision when filling casings or creating uniform jerky sticks. Meat presses often have larger tubes up to 2 inches or more, enabling faster filling but potentially sacrificing consistency in thickness and texture.

Paddle-style meat press

The paddle-style meat press evenly compacts thin strips of meat, ensuring consistent thickness critical for uniform dehydration in jerky making. Unlike jerky guns that produce ground-like texture, the paddle press maintains the meat's fibrous integrity, resulting in traditional, chewy jerky favored for flavor and texture.

Jerky gun vs meat press for making jerky. Infographic

cookingdiff.com

cookingdiff.com