Dehydrating herbs removes moisture slowly using low heat and air circulation, preserving flavor and potency over time. Infrared drying uses radiant heat to penetrate plant material, accelerating water evaporation while maintaining the integrity of essential oils. Choosing between dehydrating and infrared drying depends on whether preserving delicate aromas or reducing drying time is the priority in herb preparation.

Table of Comparison

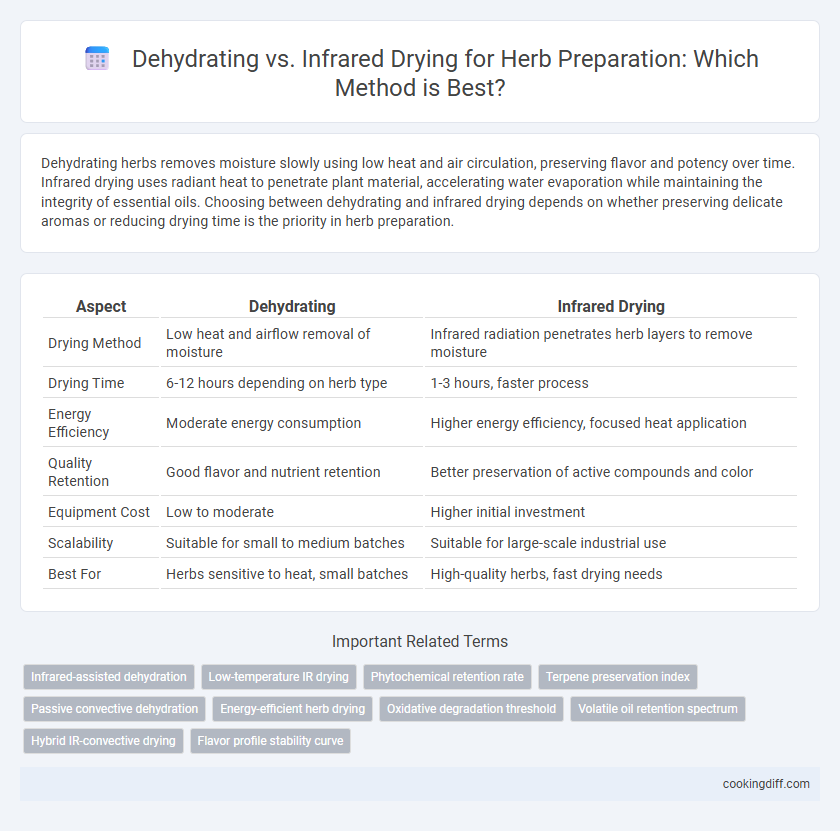

| Aspect | Dehydrating | Infrared Drying |

|---|---|---|

| Drying Method | Low heat and airflow removal of moisture | Infrared radiation penetrates herb layers to remove moisture |

| Drying Time | 6-12 hours depending on herb type | 1-3 hours, faster process |

| Energy Efficiency | Moderate energy consumption | Higher energy efficiency, focused heat application |

| Quality Retention | Good flavor and nutrient retention | Better preservation of active compounds and color |

| Equipment Cost | Low to moderate | Higher initial investment |

| Scalability | Suitable for small to medium batches | Suitable for large-scale industrial use |

| Best For | Herbs sensitive to heat, small batches | High-quality herbs, fast drying needs |

Introduction to Herb Drying Techniques

Dehydrating is a traditional herb drying technique that involves removing moisture using low heat over an extended period. Infrared drying uses infrared radiation to penetrate herbs and evaporate moisture quickly, preserving volatile oils and active compounds.

Herb dehydrators provide consistent airflow and temperature control, ideal for delicate leaves and flowers. Infrared drying offers faster processing times and enhanced retention of aroma and color, making it a modern alternative in herb preparation.

What is Traditional Dehydrating?

Traditional dehydrating uses low heat and airflow to slowly remove moisture from herbs, preserving flavor and nutrients. This method typically involves a dehydrator or an oven set at low temperatures over several hours.

- Natural airflow process - Uses fans or vents to circulate warm air, facilitating gradual drying.

- Extended drying time - Can take 6 to 12 hours depending on herb moisture content and thickness.

- Preserves herb quality - Maintains essential oils and flavor compounds better than high-heat alternatives.

Understanding Infrared Drying Technology

Infrared drying technology uses infrared radiation to heat herbs directly, speeding up moisture evaporation while preserving essential oils and nutrients. This method offers more uniform drying compared to traditional dehydrating, reducing the risk of uneven texture and color degradation.

- Faster Drying Time - Infrared drying accelerates herb dehydration by penetrating plant material, minimizing surface drying resistance.

- Energy Efficiency - Infrared systems consume less energy by targeting water molecules directly rather than heating ambient air.

- Quality Preservation - Infrared drying maintains higher levels of volatile compounds and antioxidants beneficial for herbal quality.

Efficiency Comparison: Dehydrating vs Infrared Drying

| Method | Energy Consumption | Drying Time | Retention of Herbal Properties |

|---|---|---|---|

| Dehydrating | Moderate energy use, typically 300-700 watts | 6-12 hours depending on herb and conditions | High retention of flavor and essential oils when temperature controlled |

| Infrared Drying | Lower overall energy consumption due to direct heat transfer | 1-3 hours, significantly reducing processing time | Effective retention of bioactive compounds but may risk overheating sensitive herbs |

Effects on Herb Flavor and Aroma

Dehydrating herbs at low temperatures preserves delicate essential oils, maintaining the natural flavor and aroma more effectively than high-heat methods. Infrared drying, while faster, can cause partial volatilization of these oils, resulting in a diminished herb fragrance and altered taste profile.

Studies show dehydrated herbs retain up to 85% of their original aromatic compounds compared to infrared drying's 60-70% retention. This makes traditional dehydration preferable for culinary and medicinal herbs where flavor intensity and aroma fidelity are critical.

Impact on Nutritional Content

Dehydrating herbs typically preserves more heat-sensitive vitamins like vitamin C compared to infrared drying, which uses higher temperatures that may degrade these nutrients. Infrared drying often results in faster moisture removal but can lead to greater nutrient loss, especially in antioxidants and volatile oils.

- Dehydrating retains vitamin C - Low temperatures used in dehydrating help maintain higher levels of heat-sensitive vitamins.

- Infrared drying accelerates drying time - Infrared radiation penetrates the herb quickly, reducing total drying duration but increasing nutrient degradation risk.

- Nutrient retention varies by method - The choice between dehydrating and infrared drying affects antioxidant and essential oil preservation in herbs.

Choosing dehydrating methods optimizes nutritional content retention in herb preparation more effectively than infrared drying.

Energy Consumption and Environmental Considerations

Dehydrating herbs using traditional methods typically consumes more energy compared to infrared drying due to longer processing times and higher temperature requirements. Infrared drying offers enhanced energy efficiency by directly targeting water molecules, reducing overall energy consumption and carbon footprint. Environmentally, infrared drying minimizes emissions and preserves herb quality, making it a more sustainable option for herb preparation.

Equipment Costs and Accessibility

Dehydrating herbs typically requires affordable and widely available equipment like household food dehydrators, making it accessible for small-scale or home use. Infrared drying systems involve higher initial investment due to advanced technology and specialized components, limiting accessibility for casual herb preparers. The lower equipment costs and ease of use make traditional dehydrators a preferred choice for many herb enthusiasts focused on cost-effective preparation.

Practical Applications for Home Herb Preparation

Dehydrating herbs using traditional methods like air drying or electric dehydrators preserves flavor and potency by removing moisture slowly and evenly. Infrared drying offers faster drying times but may cause uneven heat exposure, potentially reducing the quality of delicate herbs.

For home herb preparation, dehydrating is practical and cost-effective, requiring minimal equipment and maintaining herb integrity. Infrared drying suits faster processes but demands precise control to prevent damage, making it less ideal for small-scale use. Choosing the right method depends on the herb type, desired flavor retention, and available resources.

Related Important Terms

Infrared-assisted dehydration

Infrared-assisted dehydration enhances herb preparation by rapidly removing moisture while preserving essential oils and active compounds, outperforming traditional dehydrating methods in efficiency and quality retention. This technique utilizes infrared radiation to penetrate herb tissues, enabling uniform drying and minimizing nutrient loss compared to conventional air dehydration.

Low-temperature IR drying

Low-temperature infrared drying preserves the volatile oils and active compounds in herbs more effectively than traditional dehydrating methods by using controlled radiant heat below 60degC, minimizing nutrient degradation and color loss. This technique ensures faster moisture removal with better texture retention, making it ideal for delicate herb preparation where quality and potency are critical.

Phytochemical retention rate

Dehydrating preserves a higher phytochemical retention rate in herbs compared to infrared drying, which can cause heat-induced degradation of sensitive compounds. Studies indicate that traditional dehydrating methods maintain up to 85% of essential phytochemicals, whereas infrared drying often reduces this retention to around 65%.

Terpene preservation index

Dehydrating herbs at low temperatures maintains a higher Terpene Preservation Index (TPI), typically around 85-90%, compared to Infrared Drying, which averages a TPI of 60-70% due to heat-induced terpene degradation. This preservation advantage directly impacts the aroma and therapeutic efficacy of the prepared herbs, making traditional dehydrating methods preferable for maximizing terpene retention.

Passive convective dehydration

Passive convective dehydration for herb preparation relies on natural airflow and ambient temperature to remove moisture, preserving delicate flavors and essential oils without heat damage. Infrared drying uses radiation to rapidly penetrate and heat herb tissues, accelerating moisture removal but potentially causing loss of volatile compounds and altered aroma profiles.

Energy-efficient herb drying

Dehydrating herbs typically consumes more energy due to longer drying times at lower temperatures, while infrared drying offers rapid moisture removal with reduced energy use by directly heating the herb's surface. Infrared drying enhances energy efficiency in herb preparation by minimizing heat exposure and preserving essential oils, making it a superior method for sustainable herb drying.

Oxidative degradation threshold

Dehydrating herbs typically involves lower temperatures that reduce the risk of surpassing the oxidative degradation threshold, preserving essential oils and active compounds. Infrared drying, while faster, may generate localized heat exceeding the oxidative degradation threshold, potentially compromising herb quality and efficacy.

Volatile oil retention spectrum

Dehydrating herbs using conventional methods generally results in lower retention of volatile oils, essential for preserving the herb's aromatic and therapeutic properties, compared to infrared drying which efficiently retains a broader spectrum of these oils due to its rapid and uniform heat application. Infrared drying minimizes thermal degradation and evaporation losses of volatile compounds, ensuring higher-quality herb preparation with enhanced potency and flavor profile.

Hybrid IR-convective drying

Hybrid IR-convective drying combines the rapid surface heating of infrared radiation with the thorough moisture removal of convective air flow, resulting in more efficient dehydration of herbs with better retention of bioactive compounds and aroma. This technique significantly reduces drying time compared to conventional dehydrating while preserving color, texture, and essential oils critical for high-quality herb preparation.

Dehydrating vs Infrared Drying for herb preparation. Infographic

cookingdiff.com

cookingdiff.com