Traditional rack drying for jerky relies on natural airflow and ambient temperatures, often resulting in uneven dehydration and inconsistent texture. Smart dehydrators use precise temperature control and airflow mechanisms to ensure uniform drying, enhancing flavor retention and food safety. This technology reduces drying time and minimizes nutrient loss compared to conventional rack methods.

Table of Comparison

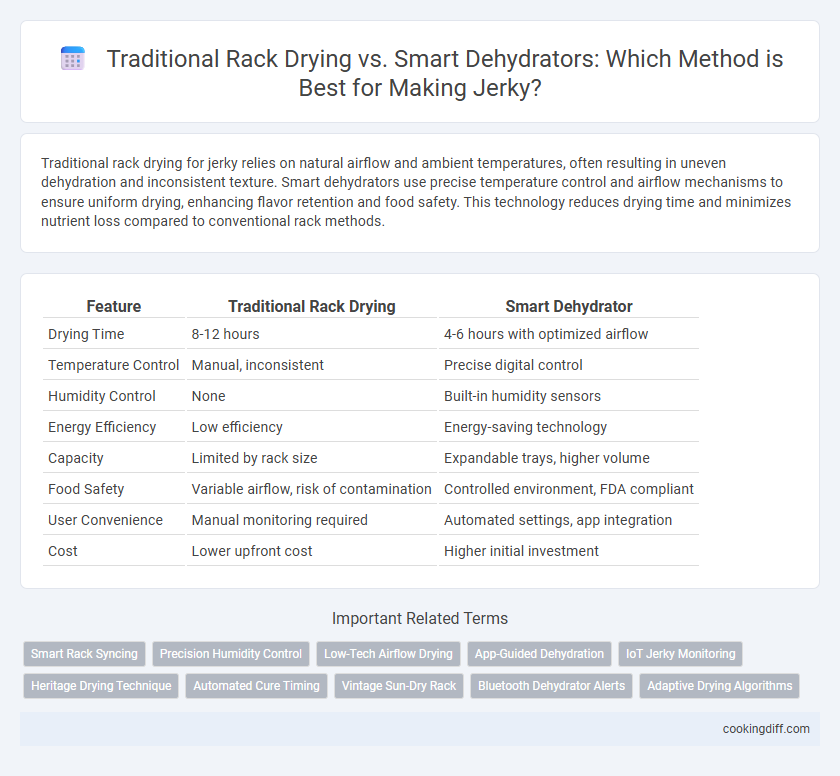

| Feature | Traditional Rack Drying | Smart Dehydrator |

|---|---|---|

| Drying Time | 8-12 hours | 4-6 hours with optimized airflow |

| Temperature Control | Manual, inconsistent | Precise digital control |

| Humidity Control | None | Built-in humidity sensors |

| Energy Efficiency | Low efficiency | Energy-saving technology |

| Capacity | Limited by rack size | Expandable trays, higher volume |

| Food Safety | Variable airflow, risk of contamination | Controlled environment, FDA compliant |

| User Convenience | Manual monitoring required | Automated settings, app integration |

| Cost | Lower upfront cost | Higher initial investment |

Introduction to Jerky Dehydration Methods

Jerky dehydration methods vary significantly between traditional rack drying and modern smart dehydrators, impacting efficiency and product consistency. Each method offers unique advantages in temperature control and drying time, essential for optimal jerky quality.

- Traditional Rack Drying - Utilizes natural airflow and ambient temperatures, requiring longer drying times and manual monitoring to prevent spoilage.

- Smart Dehydrators - Employ precise temperature and humidity controls with digital settings, enhancing consistency and reducing drying duration.

- Energy Efficiency - Smart dehydrators generally consume less energy due to optimized cycles, whereas traditional racks depend on external conditions and may be less energy efficient.

Overview of Traditional Rack Drying

Traditional rack drying for jerky involves hanging meat strips on racks in a controlled environment to remove moisture through natural airflow and low heat. This method relies heavily on ambient conditions and manual monitoring to ensure proper dehydration.

- Airflow Dependent - Drying efficiency depends on natural airflow circulation around the racks.

- Time-Intensive - The dehydration process can take several hours to days depending on environmental factors.

- Manual Oversight - Requires frequent checking to prevent spoilage and ensure even drying.

Traditional rack drying offers a low-tech, cost-effective method but lacks the precision and consistency of modern smart dehydrators.

What Is a Smart Dehydrator?

A smart dehydrator is an advanced device designed to precisely control temperature and drying time through digital interfaces and sensors. Unlike traditional rack drying, it ensures consistent dehydration, reducing the risk of over-drying or under-drying jerky.

Smart dehydrators utilize Wi-Fi connectivity and mobile app integration to monitor and adjust settings remotely, enhancing user convenience and efficiency. These features enable real-time alerts and custom drying programs tailored for different types of meat. This technology results in higher-quality jerky with improved texture and flavor retention compared to conventional rack drying methods.

Efficiency Comparison: Rack Drying vs Smart Dehydrator

Traditional rack drying for jerky relies on ambient air circulation and can take up to 24 hours, often resulting in uneven moisture removal and potential bacterial growth. In contrast, smart dehydrators use precise temperature controls and timed airflow to reduce drying time to 6-8 hours with consistent humidity levels.

Smart dehydrators optimize energy usage through programmable settings, achieving up to 30% greater efficiency compared to rack drying methods. This technology ensures uniform dehydration and higher product safety, making it superior for both small-scale and commercial jerky production.

Flavor and Texture Differences

| Traditional Rack Drying | Produces jerky with uneven texture due to inconsistent airflow, often resulting in tougher pieces and less uniform flavor distribution. Natural air drying can enhance smoky, rustic flavors but may risk over-drying or uneven seasoning absorption. |

| Smart Dehydrator | Offers precise temperature and humidity control, yielding consistently tender jerky with balanced moisture and enhanced flavor penetration. Advanced airflow systems reduce drying time while preserving the meat's natural taste and ideal chewiness. |

Safety and Hygiene Considerations

How do safety and hygiene compare between traditional rack drying and using a smart dehydrator for jerky? Traditional rack drying can expose jerky to contaminants due to open-air conditions and inconsistent temperature control. Smart dehydrators maintain precise temperature regulation and airflow, significantly reducing the risk of bacterial growth and ensuring a safer, more hygienic drying process.

Energy Consumption and Cost Analysis

Traditional rack drying for jerky typically consumes more energy due to longer drying times and less efficient heat distribution, leading to higher electricity bills. Smart dehydrators use advanced sensors and automated controls to optimize drying cycles, significantly reducing energy usage and operational costs. Over time, smart dehydrators lower overall expenses despite a higher initial investment, making them a cost-effective solution for jerky dehydration.

Ease of Use and Convenience

Traditional rack drying requires manual monitoring and frequent turning of the jerky, making the process labor-intensive and time-consuming. Smart dehydrators feature programmable settings and automatic timers that simplify the drying process, allowing users to set and forget. These advanced devices also offer consistent temperature control, enhancing convenience by ensuring evenly dried jerky without constant supervision.

Suitability for Beginners and Experts

Traditional rack drying offers a straightforward, low-tech method ideal for beginners who appreciate simplicity and cost-effectiveness in preparing jerky. Its hands-on approach provides clear control over drying time and temperature but requires close monitoring to prevent spoilage.

Smart dehydrators, equipped with precise temperature controls and programmable settings, cater to both novices and experts seeking consistent results with minimal effort. Advanced models feature connectivity options and preset functions, enabling users to customize drying cycles for various jerky recipes efficiently.

Related Important Terms

Smart Rack Syncing

Smart dehydrators with Smart Rack Syncing optimize jerky drying by automatically adjusting temperature and airflow per rack, ensuring even dehydration and superior texture. Traditional rack drying lacks this technology, often resulting in uneven drying and inconsistent jerky quality.

Precision Humidity Control

Traditional rack drying methods lack precision humidity control, often resulting in inconsistent jerky texture and moisture levels, which can compromise both safety and flavor. Smart dehydrators utilize advanced sensors to maintain optimal humidity, ensuring even drying and superior preservation of jerky quality.

Low-Tech Airflow Drying

Traditional rack drying for jerky relies on low-tech airflow drying methods that use ambient air circulation and natural ventilation, often leading to inconsistent moisture removal and longer drying times. Smart dehydrators employ precise temperature and airflow control, optimizing dehydration efficiency and ensuring uniform jerky texture while minimizing the risk of spoilage.

App-Guided Dehydration

App-guided dehydration in smart dehydrators offers precise temperature control and customizable drying times for jerky, ensuring consistent texture and enhanced flavor retention. Traditional rack drying lacks real-time monitoring and data-driven adjustments, often leading to uneven drying and higher risk of spoilage.

IoT Jerky Monitoring

Traditional rack drying relies on manual temperature and humidity adjustments, often leading to inconsistent jerky texture and potential spoilage. Smart dehydrators equipped with IoT sensors enable real-time monitoring and precise control of drying conditions, ensuring optimal jerky preservation and uniform quality.

Heritage Drying Technique

Traditional rack drying preserves jerky using slow, natural airflow and low heat, maintaining authentic flavor and texture through time-honored heritage drying techniques. In contrast, smart dehydrators employ precise temperature control and humidity regulation to enhance consistency and reduce drying time while respecting traditional jerky-making methods.

Automated Cure Timing

Smart dehydrators for jerky utilize automated cure timing technology, precisely controlling drying cycles based on moisture content and temperature sensors to ensure consistent texture and flavor. Traditional rack drying relies on manual monitoring, which often leads to uneven curing and increased risk of bacterial growth.

Vintage Sun-Dry Rack

The Vintage Sun-Dry Rack provides a natural, cost-effective method for dehydrating jerky by utilizing solar energy and open-air airflow, preserving authentic flavors without electrical usage. Compared to smart dehydrators, it lacks precise temperature control and faster drying times but offers an eco-friendly solution with a rustic appeal for artisanal jerky makers.

Bluetooth Dehydrator Alerts

Traditional rack drying relies on manual monitoring, increasing the risk of uneven dehydration and spoilage, while smart dehydrators with Bluetooth alerts provide real-time notifications on temperature and humidity levels, ensuring consistent jerky quality and energy efficiency. Bluetooth-enabled dehydrator alerts optimize drying cycles by automatically adjusting settings and preventing over-drying, making the jerky preparation process more precise and reliable.

Traditional rack drying vs Smart dehydrator for jerky. Infographic

cookingdiff.com

cookingdiff.com