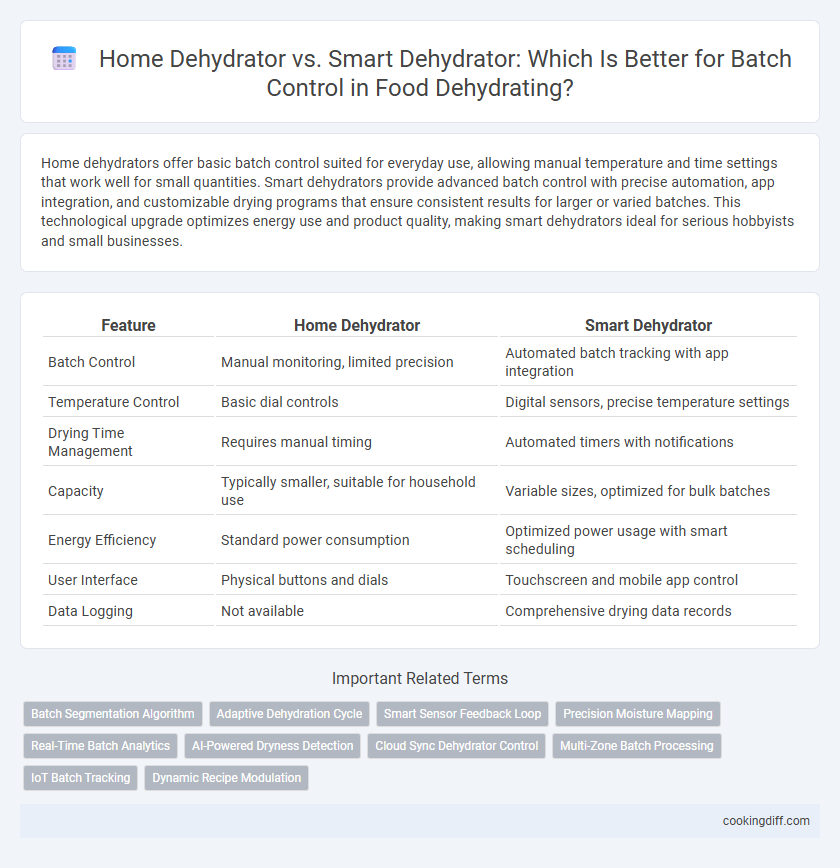

Home dehydrators offer basic batch control suited for everyday use, allowing manual temperature and time settings that work well for small quantities. Smart dehydrators provide advanced batch control with precise automation, app integration, and customizable drying programs that ensure consistent results for larger or varied batches. This technological upgrade optimizes energy use and product quality, making smart dehydrators ideal for serious hobbyists and small businesses.

Table of Comparison

| Feature | Home Dehydrator | Smart Dehydrator |

|---|---|---|

| Batch Control | Manual monitoring, limited precision | Automated batch tracking with app integration |

| Temperature Control | Basic dial controls | Digital sensors, precise temperature settings |

| Drying Time Management | Requires manual timing | Automated timers with notifications |

| Capacity | Typically smaller, suitable for household use | Variable sizes, optimized for bulk batches |

| Energy Efficiency | Standard power consumption | Optimized power usage with smart scheduling |

| User Interface | Physical buttons and dials | Touchscreen and mobile app control |

| Data Logging | Not available | Comprehensive drying data records |

Understanding Batch Control in Food Dehydration

Home dehydrators offer basic batch control with manual temperature and time settings, suitable for small-scale dehydration projects. They rely on user intervention to monitor and adjust conditions, which can affect consistency and quality of the dried food.

Smart dehydrators integrate advanced sensors and automated controls to precisely manage temperature, humidity, and drying time for each batch. This technology enhances batch consistency, ensures optimal preservation of nutrients, and reduces the risk of over- or under-drying.

Key Features of Home Dehydrators

Home dehydrators are designed for simplicity and ease of use, ideal for small to medium batches of food preservation. They emphasize manual batch control, allowing users to adjust settings without relying on automated systems.

- Manual Temperature Control - Users can set and adjust drying temperatures directly for precise dehydration.

- Compact Design - Typically smaller in size, suitable for countertop use and limited space.

- Affordable Price Point - Generally more budget-friendly compared to smart dehydrators.

Home dehydrators provide reliable batch control through straightforward mechanical settings, making them practical for everyday use.

Advanced Capabilities of Smart Dehydrators

Smart dehydrators offer advanced batch control features such as precise temperature regulation, programmable drying cycles, and real-time monitoring through connected apps. These capabilities enable consistent moisture removal and better preservation of nutrients compared to traditional home dehydrators. Automated alerts and data tracking further optimize the dehydration process, enhancing efficiency and product quality.

Precision and Consistency in Batch Drying

How do home dehydrators compare to smart dehydrators in precision and consistency for batch drying? Home dehydrators often rely on manual settings, which can lead to variability in moisture levels and uneven drying across batches. Smart dehydrators utilize advanced sensors and automated controls to maintain consistent temperature and humidity, ensuring precise and repeatable results every time.

Automation and Remote Monitoring

Home dehydrators offer manual batch control, requiring users to monitor and adjust settings physically, which can be time-consuming and less precise. Smart dehydrators utilize automation and remote monitoring through connected apps, allowing users to control temperature and drying time from anywhere, enhancing efficiency and consistency. These advanced features reduce human error and optimize dehydration processes for large or multiple batches, making them ideal for serious food preservation enthusiasts.

Energy Efficiency in Batch Operations

Home dehydrators typically consume more energy per batch due to less precise temperature control and longer drying times. Smart dehydrators optimize energy efficiency by using sensors and automated batch controls to minimize power usage during the dehydration process.

Smart dehydrators leverage advanced algorithms to adjust drying cycles based on batch size and humidity levels, significantly reducing energy waste. These devices enhance batch consistency while allowing users to monitor energy consumption in real-time via connected apps. Energy efficiency gains in smart dehydrators translate to lower electricity costs and reduced environmental impact over time.

User Interface and Control Options

Home dehydrators typically feature basic user interfaces with manual knobs and limited temperature settings, offering straightforward control ideal for small batches. These devices often lack programmable cycles, requiring users to monitor progress manually, which may be less efficient for precise batch control.

Smart dehydrators incorporate digital touchscreens and app connectivity, providing advanced control options like preset drying programs and real-time batch monitoring. These interfaces enable users to customize temperature and time remotely, ensuring consistent results across larger or multiple batches with minimal supervision.

Cost Comparison and Value for Batch Dehydration

| Aspect | Home Dehydrator | Smart Dehydrator |

|---|---|---|

| Initial Cost | Typically ranges from $50 to $150, suitable for small batch dehydration needs. | Ranges between $200 and $500, reflecting advanced technology and automated controls. |

| Energy Efficiency | Lower energy efficiency with manual temperature and timing control, potentially increasing electricity costs. | Enhanced energy efficiency through precise temperature regulation and programmable batch settings. |

| Batch Control | Limited batch size and uniformity, requiring frequent monitoring and manual adjustments. | Supports larger batch sizes with customizable drying schedules, optimizing batch consistency and quality. |

| Long-Term Value | Cost-effective for occasional use, but may incur higher operational costs with inconsistent drying results. | Higher upfront investment offset by time savings, improved product quality, and reduced waste for frequent batch dehydration. |

Maintenance and Troubleshooting for Batch Management

Maintaining a home dehydrator requires regular cleaning and manual monitoring to prevent overheating and uneven drying, which can complicate batch control. Smart dehydrators feature automated sensors and alerts that streamline troubleshooting and ensure consistent batch quality with minimal user intervention.

- Home Dehydrator Cleaning - Requires disassembling trays and wiping heating elements to avoid residue buildup affecting drying performance.

- Smart Dehydrator Alerts - Uses real-time data to notify users of temperature fluctuations or fan malfunctions for prompt troubleshooting.

- Batch Consistency - Smart dehydrators maintain uniform drying conditions through integrated batch control software, reducing manual oversight.

Related Important Terms

Batch Segmentation Algorithm

Home dehydrators typically offer manual batch control, limiting precision in drying cycles, whereas smart dehydrators utilize advanced batch segmentation algorithms to optimize dehydration by dynamically adjusting temperature and time for each batch segment, enhancing consistency and energy efficiency. The batch segmentation algorithm analyzes moisture levels and drying rates within segmented batches, enabling real-time adjustments that improve product quality and reduce processing time significantly.

Adaptive Dehydration Cycle

Home dehydrators provide consistent drying with fixed temperature settings, while smart dehydrators utilize Adaptive Dehydration Cycles that automatically adjust humidity and airflow for precise batch control. This technology optimizes moisture removal and energy efficiency by continuously monitoring and adapting to the specific drying needs of each batch.

Smart Sensor Feedback Loop

Smart dehydrators utilize advanced sensor feedback loops that continuously monitor temperature and humidity, enabling precise batch control for consistent drying results. Home dehydrators often lack this real-time adjustment capability, leading to less uniform dehydration and potential quality variance in batches.

Precision Moisture Mapping

Home dehydrators often lack precise moisture mapping capabilities, leading to inconsistent batch drying and potential over- or under-dehydration. Smart dehydrators utilize advanced sensors and real-time data analytics to provide exact moisture level control, ensuring uniform batch processing and optimal preservation.

Real-Time Batch Analytics

Home dehydrators offer basic temperature and time controls but lack real-time batch analytics, limiting precise monitoring and optimization during dehydration. Smart dehydrators integrate advanced sensors and IoT technology, providing real-time batch data and analytics that enable precise control over moisture levels and drying consistency for superior batch quality.

AI-Powered Dryness Detection

Home dehydrators offer manual batch control relying on preset timers and temperatures, often resulting in inconsistent moisture levels. Smart dehydrators integrate AI-powered dryness detection sensors that dynamically adjust drying cycles, ensuring precise moisture removal and optimal batch consistency.

Cloud Sync Dehydrator Control

Home dehydrators typically lack cloud sync capabilities, limiting batch control to manual adjustments and local timers, while smart dehydrators offer advanced cloud sync features for real-time monitoring and precise batch management remotely. Cloud sync dehydrator control enables users to track, adjust, and automate drying cycles via smartphone apps, ensuring consistent quality and efficient energy use across multiple batches.

Multi-Zone Batch Processing

Home dehydrators typically offer single-zone drying with uniform temperature controls suitable for small batches, while smart dehydrators provide advanced multi-zone batch processing that enables independent temperature and time settings for each drying zone. This technology enhances precision and efficiency in dehydrating diverse food types simultaneously, optimizing batch control and product consistency.

IoT Batch Tracking

Smart dehydrators equipped with IoT batch tracking enable real-time monitoring and precise control over dehydration parameters, enhancing batch consistency and reducing spoilage. Home dehydrators lack integrated connectivity, limiting automated data collection and making batch tracking manual and less efficient.

Home Dehydrator vs Smart Dehydrator for batch control. Infographic

cookingdiff.com

cookingdiff.com