Bulk dehydrating saves time by processing large quantities of food simultaneously, making it ideal for those who meal prep frequently or for multiple people. Small-batch dehydrating offers greater flexibility and allows for experimentations with different recipes, perfect for varied meal plans or limited kitchen space. Both methods enhance meal prep efficiency by preserving nutrients and extending the shelf life of ingredients.

Table of Comparison

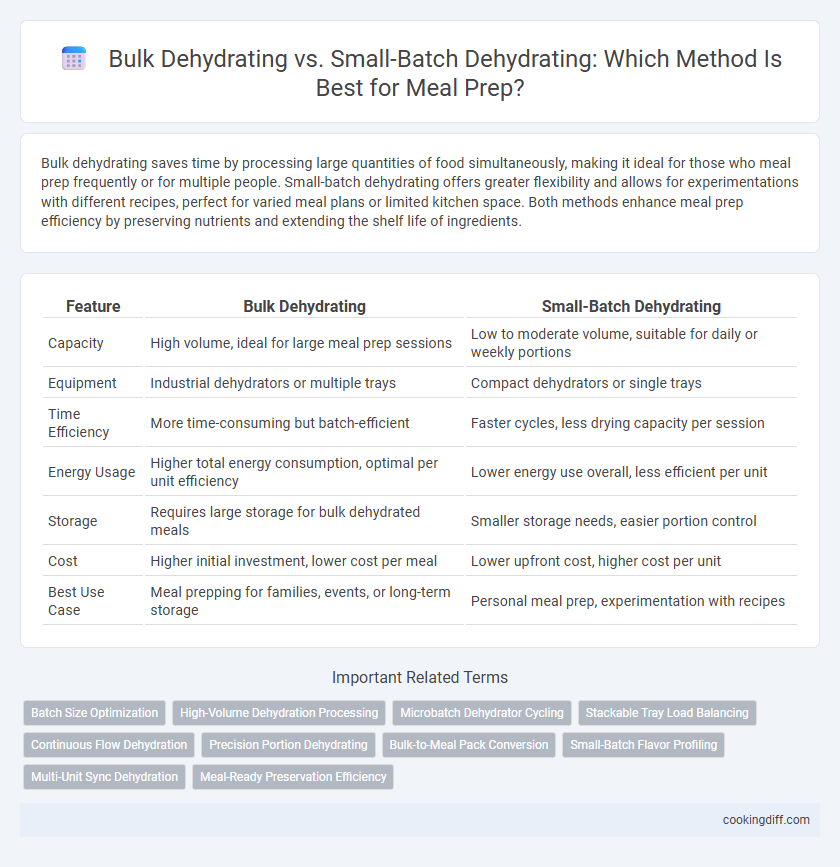

| Feature | Bulk Dehydrating | Small-Batch Dehydrating |

|---|---|---|

| Capacity | High volume, ideal for large meal prep sessions | Low to moderate volume, suitable for daily or weekly portions |

| Equipment | Industrial dehydrators or multiple trays | Compact dehydrators or single trays |

| Time Efficiency | More time-consuming but batch-efficient | Faster cycles, less drying capacity per session |

| Energy Usage | Higher total energy consumption, optimal per unit efficiency | Lower energy use overall, less efficient per unit |

| Storage | Requires large storage for bulk dehydrated meals | Smaller storage needs, easier portion control |

| Cost | Higher initial investment, lower cost per meal | Lower upfront cost, higher cost per unit |

| Best Use Case | Meal prepping for families, events, or long-term storage | Personal meal prep, experimentation with recipes |

Introduction to Bulk and Small-Batch Dehydrating

What are the key differences between bulk dehydrating and small-batch dehydrating for meal prep? Bulk dehydrating allows for processing large quantities of food simultaneously, optimizing time and energy efficiency. Small-batch dehydrating provides greater control over moisture levels and is ideal for experimenting with diverse recipes or portion sizes.

Key Differences Between Bulk and Small-Batch Dehydrating

Bulk dehydrating processes large quantities of food simultaneously, optimizing time and energy efficiency for extensive meal prep. Small-batch dehydrating focuses on smaller portions, allowing for greater control over drying times and ingredient variety.

- Capacity - Bulk dehydrating requires larger equipment to handle significant volumes, while small-batch uses compact dehydrators for limited amounts.

- Time Efficiency - Bulk dehydrating reduces overall drying time per unit of food compared to repeated small batches.

- Flexibility - Small-batch dehydrating allows for frequent recipe experimentation and portion customization.

Advantages of Bulk Dehydrating for Meal Prep

Bulk dehydrating streamlines meal prep by allowing large quantities of fruits, vegetables, and proteins to be preserved simultaneously, maximizing efficiency and reducing time spent on repetitive tasks. This method is ideal for preparing entire week's meals in advance, ensuring consistent portion control and food variety.

Storing bulk dehydrated foods requires less space compared to fresh ingredients, helping maintain an organized kitchen while extending shelf life significantly. Bulk dehydration also minimizes energy consumption by utilizing one extended drying cycle rather than multiple smaller ones.

Benefits of Small-Batch Dehydrating for Home Cooks

Small-batch dehydrating offers better control over food quality and flavor, making it ideal for home cooks focused on meal prep. It also reduces waste by allowing precise portioning and encourages experimenting with a variety of ingredients.

- Enhanced Flavor Preservation - Dehydrating smaller batches helps retain the natural taste and nutrients of food more effectively.

- Reduced Food Waste - Preparing meals in small amounts minimizes the risk of over-dehydrating or spoiling ingredients.

- Greater Ingredient Variety - Small batches enable home cooks to try different recipes and seasonal produce without large commitments.

Equipment Needed: Bulk vs Small-Batch Dehydrating

Bulk dehydrating requires industrial-grade dehydrators with large capacity trays and high wattage for efficient drying of large quantities. Small-batch dehydrating can be managed using countertop models that are compact, energy-efficient, and ideal for smaller meal prep volumes.

- Bulk dehydrators have multiple large trays - These allow simultaneous drying of various foods on a larger scale.

- High power consumption - Bulk equipment typically operates at higher wattage to maintain consistent drying temperatures over extended periods.

- Small-batch dehydrators are portable and easy to store - Designed for limited space and quick meal prep cycles.

Choosing the right equipment depends on your meal prep volume and available storage space.

Time and Energy Efficiency Comparison

Bulk dehydrating meal prep significantly reduces overall drying time by processing larger quantities simultaneously, leading to greater energy efficiency per unit of food compared to small-batch dehydrating. Small-batch dehydrating offers more precise control over drying times for varied ingredients but requires more frequent energy use due to repeated cycles. Time saved in bulk dehydrating translates directly to lower electricity consumption, making it the more efficient option for large-scale meal preparation.

Storage and Shelf Life Considerations

Bulk dehydrating requires ample, airtight storage containers to prevent moisture exposure, which can significantly extend the shelf life of meals, often lasting 6 to 12 months when stored properly. Small-batch dehydrated food typically has a shorter shelf life of 3 to 6 months but offers greater flexibility for rotation and consumption.

Proper storage conditions for bulk-dehydrated meals include cool, dark environments and vacuum sealing to maintain freshness and nutrient retention. Small-batch dehydrating allows for quicker consumption cycles, reducing the risk of spoilage and waste. Both methods benefit from oxygen absorbers and moisture-proof packaging to optimize shelf life and meal prep efficiency.

Cost-Effectiveness: Bulk vs Small-Batch Dehydrating

Bulk dehydrating significantly lowers the cost per meal by maximizing energy efficiency and reducing packaging expenses. Small-batch dehydrating allows for flexibility in meal variety but often results in higher utility bills and consumable costs due to frequent equipment use. Comparing overall expenses reveals bulk dehydrating as the more cost-effective method for large-scale meal prep, while small-batch suits personalized or experimental cooking needs.

Best Foods for Bulk and Small-Batch Dehydrating

| Bulk Dehydrating | Small-Batch Dehydrating |

|---|---|

| Best for high-volume foods like fruits (apples, bananas), vegetables (peppers, tomatoes), and meats suited for jerky preparation. Efficient for meal preps that require consistent large quantities. Ideal for preserving staple ingredients long-term. | Optimal for delicate items such as herbs (basil, parsley), small amounts of berries, and individual portion vegetables. Allows better control over drying time and texture for diverse meal variations. Perfect for experimenting with flavors or specialty ingredients. |

Related Important Terms

Batch Size Optimization

Bulk dehydrating maximizes efficiency by processing large quantities of food simultaneously, reducing overall dehydration time and energy consumption, ideal for meal prepping families or weekly plans. Small-batch dehydrating offers precise control over drying times and quality, allowing for tailored portions and minimizing food waste in single or couple meal preps.

High-Volume Dehydration Processing

High-volume dehydration processing in bulk dehydrating enables efficient preservation of large quantities of food simultaneously, significantly reducing time and energy costs compared to small-batch methods. Industrial-grade dehydrators with robust airflow and temperature controls ensure consistent moisture removal, maintaining nutritional value and extending shelf life for meal prep at scale.

Microbatch Dehydrator Cycling

Microbatch dehydrator cycling enhances precision in small-batch dehydrating by allowing controlled temperature and humidity adjustments, optimizing nutrient retention and flavor profiles for meal prep. Bulk dehydrating prioritizes volume over cycling frequency, potentially compromising uniform drying but improving efficiency for large-scale food preservation.

Stackable Tray Load Balancing

Stackable tray load balancing in bulk dehydrating ensures even air circulation and consistent moisture removal across multiple trays, optimizing drying efficiency for large meal prep volumes. Small-batch dehydrating benefits from fewer trays, allowing precise control over load distribution and minimizing uneven drying, ideal for customized meal portions.

Continuous Flow Dehydration

Continuous flow dehydration enables efficient bulk dehydrating by maintaining consistent airflow and temperature, maximizing moisture removal and reducing overall drying time for large meal prep batches. Unlike small-batch dehydrating, this method minimizes nutrient loss and enhances shelf life, making it ideal for high-volume meal preparation.

Precision Portion Dehydrating

Precision portion dehydrating in small-batch dehydrating allows for customizable control over moisture levels and portion sizes, ensuring optimal texture and nutrient retention for each meal component. Bulk dehydrating, while efficient for large quantities, often sacrifices this level of precision, leading to inconsistent dehydration and potential quality loss in meal prep.

Bulk-to-Meal Pack Conversion

Bulk dehydrating efficiently transforms large quantities of ingredients into lightweight, shelf-stable components, maximizing storage space and reducing preparation time for meal packs. Small-batch dehydrating offers precise portion control and customization, ideal for tailoring individual meal packs to specific dietary needs or flavor profiles.

Small-Batch Flavor Profiling

Small-batch dehydrating allows for precise flavor profiling by enabling cooks to experiment with seasoning blends and ingredient combinations on a manageable scale, enhancing the complexity and customization of meal prep. This method preserves the freshness and intensity of flavors better than bulk dehydrating, which often sacrifices taste consistency due to larger volume processing.

Multi-Unit Sync Dehydration

Multi-unit sync dehydration optimizes bulk dehydrating by simultaneously processing multiple trays, enhancing efficiency and consistency in meal prep. This method reduces drying time and energy use compared to small-batch dehydrating, delivering uniformly dehydrated ingredients essential for large-scale meal preparation.

Bulk Dehydrating vs Small-Batch Dehydrating for meal prep. Infographic

cookingdiff.com

cookingdiff.com