Convection dehydrators use hot air circulation to evenly remove moisture from jerky, ensuring consistent drying and a traditional texture. Infrared dehydrators penetrate meat fibers with infrared heat, reducing drying time while retaining more flavor and nutrients. Choosing between them depends on whether you prioritize speed and nutrient preservation or uniform drying and texture control.

Table of Comparison

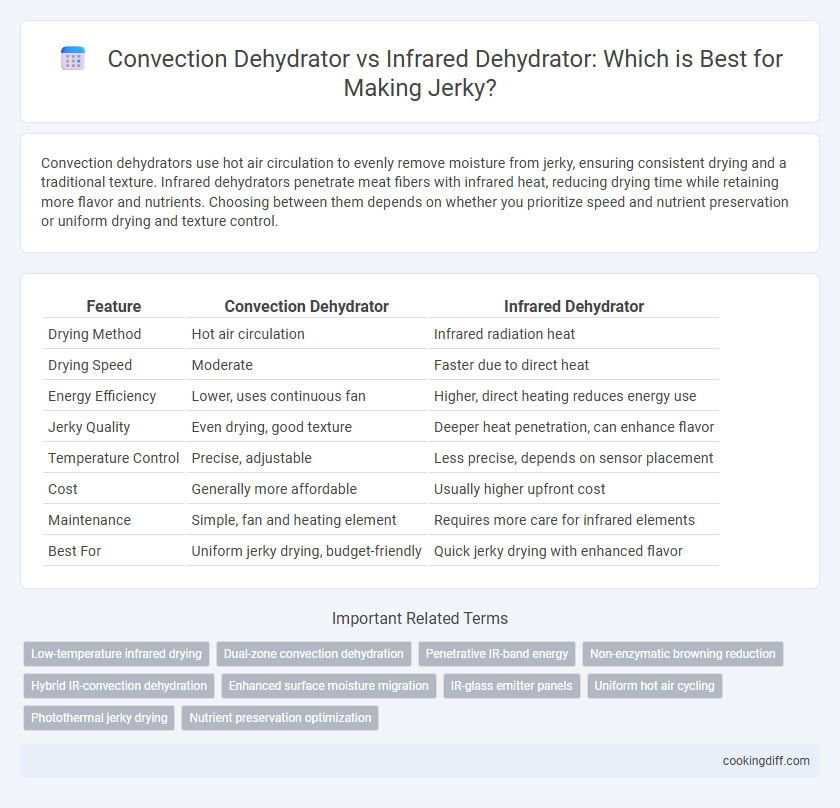

| Feature | Convection Dehydrator | Infrared Dehydrator |

|---|---|---|

| Drying Method | Hot air circulation | Infrared radiation heat |

| Drying Speed | Moderate | Faster due to direct heat |

| Energy Efficiency | Lower, uses continuous fan | Higher, direct heating reduces energy use |

| Jerky Quality | Even drying, good texture | Deeper heat penetration, can enhance flavor |

| Temperature Control | Precise, adjustable | Less precise, depends on sensor placement |

| Cost | Generally more affordable | Usually higher upfront cost |

| Maintenance | Simple, fan and heating element | Requires more care for infrared elements |

| Best For | Uniform jerky drying, budget-friendly | Quick jerky drying with enhanced flavor |

Introduction: Dehydrating Jerky – Convection vs Infrared

Convection dehydrators use circulating hot air to evenly remove moisture from jerky, ensuring consistent drying and preventing spoilage. Infrared dehydrators employ infrared radiation to penetrate the meat, speeding up the drying process and preserving nutrients and flavor. Choosing between convection and infrared methods affects drying time, energy efficiency, and final jerky texture.

How Convection Dehydrators Work for Jerky

Convection dehydrators use a fan to circulate hot air evenly around the jerky, ensuring consistent moisture removal and uniform drying. This airflow speeds up evaporation, reducing drying time and preventing spoilage.

The temperature range typically maintained is between 130degF to 160degF, ideal for safely drying meat without cooking it. These dehydrators promote efficient airflow, which helps preserve flavor and texture in the jerky.

Infrared Dehydrators: Technology and Process

Infrared dehydrators use radiant heat to penetrate meat fibers, drying jerky more evenly and efficiently compared to traditional convection methods. This technology reduces drying time and helps preserve the jerky's natural flavors and nutrients.

- Radiant Heat Penetration - Infrared waves directly heat the meat, ensuring consistent moisture removal throughout the jerky.

- Shorter Drying Times - The efficient heat transfer accelerates dehydration, reducing total drying duration significantly.

- Enhanced Flavor Retention - Lower exposure to hot air helps maintain the jerky's taste and nutritional profile better than convection dehydrators.

Heat Distribution and Drying Uniformity

Convection dehydrators use a fan to circulate hot air evenly around the jerky, ensuring consistent heat distribution and reducing drying time. Infrared dehydrators rely on radiant heat, which can create hotspots and lead to uneven drying if the jerky is not rotated regularly.

Heat distribution in convection dehydrators promotes uniform moisture removal, preventing the growth of bacteria and mold during the drying process. Infrared dehydrators offer faster surface drying due to direct radiant energy but may result in a tougher exterior and uneven interior if not carefully monitored. Choosing between the two depends on the desired jerky texture and drying efficiency.

Time Efficiency: Which Method Dries Jerky Faster?

Infrared dehydrators dry jerky faster due to direct heat penetration, reducing overall drying time significantly. Convection dehydrators rely on air circulation, which typically extends the dehydration process.

- Infrared technology - Provides rapid heat transfer that speeds up moisture removal from jerky.

- Airflow efficiency - Convection dehydrators use consistent airflow but require more time due to indirect heating.

- Energy consumption - Infrared dehydrators often consume less energy per batch thanks to shorter drying cycles.

Energy Consumption: Convection vs Infrared Dehydrators

Convection dehydrators use a fan to circulate hot air, resulting in moderate energy consumption around 300-600 watts per hour. Infrared dehydrators employ radiant heat that penetrates food directly, often consuming less energy, typically between 150-400 watts per hour. For jerky drying, infrared dehydrators provide a more energy-efficient option while maintaining effective moisture removal.

Flavor and Texture Differences in Jerky

Convection dehydrators circulate warm air to remove moisture evenly, enhancing the traditional smoky flavor and chewy texture of jerky. Infrared dehydrators use radiant heat that penetrates meat quickly, preserving more natural juices and resulting in a tender, flavorful bite.

- Convection dehydrators - Promote consistent drying that intensifies the smoky aroma and firm texture of jerky.

- Infrared dehydrators - Retain more moisture inside the jerky, creating a juicier and softer final product.

- Flavor impact - Convection methods tend to enrich savory notes, while infrared preserves subtle meat flavors without overcooking.

The choice between convection and infrared dehydrators significantly affects the flavor depth and texture quality of homemade jerky.

Ease of Use and Maintenance Comparison

| Feature | Convection Dehydrator | Infrared Dehydrator |

|---|---|---|

| Ease of Use | Simple controls and straightforward operation, ideal for beginners making jerky; requires even stacking of trays for consistent airflow. | Offers precise temperature control with quick heating, reducing drying time; may require technical knowledge to optimize settings for jerky. |

| Maintenance | Easy to clean with removable trays and accessible interior; occasional fan cleaning needed to prevent dust buildup. | Requires careful handling of infrared elements and sensors during cleaning; more delicate components increase maintenance complexity. |

Cost Analysis: Initial Investment and Operating Expenses

Convection dehydrators typically have a lower initial investment cost, often ranging from $50 to $200, while infrared dehydrators can cost between $200 and $500 due to advanced heating technology. Operating expenses for convection models are generally higher because they rely on fans and longer drying times, increasing electricity usage.

Infrared dehydrators offer more energy-efficient drying, potentially reducing operating costs by up to 30% compared to convection units. Higher upfront costs may be offset by savings in electricity and faster dehydration times, especially for jerky production on a larger scale.

Related Important Terms

Low-temperature infrared drying

Low-temperature infrared drying in infrared dehydrators preserves jerky's texture and nutrients by evenly penetrating meat fibers, reducing drying time compared to convection dehydrators that rely on hot air circulation for moisture removal. Infrared technology minimizes oxidation and microbial growth, resulting in safer, higher-quality jerky with enhanced flavor retention.

Dual-zone convection dehydration

Dual-zone convection dehydrators provide precise temperature control and even airflow, ensuring consistent moisture removal and optimal texture in jerky, whereas infrared dehydrators use radiative heat that can result in uneven drying and potential surface overheating. The dual-zone feature in convection models allows customized drying conditions for different meat thicknesses, improving flavor retention and reducing drying time compared to single-zone or infrared methods.

Penetrative IR-band energy

Infrared dehydrators utilize penetrative IR-band energy that directly heats jerky's internal moisture, resulting in faster, more uniform drying compared to convection dehydrators which rely on hot air circulation around the surface. This IR energy enhances dehydration efficiency by reducing drying time and preserving the jerky's texture and flavor through deeper heat penetration.

Non-enzymatic browning reduction

Convection dehydrators use hot air circulation to evenly dry jerky while minimizing non-enzymatic browning by maintaining lower surface temperatures. Infrared dehydrators, by directly emitting energy to heat the meat's surface, can accelerate Maillard reactions, increasing browning and potentially altering flavor profiles.

Hybrid IR-convection dehydration

Hybrid IR-convection dehydration combines the rapid heat transfer of infrared radiation with the consistent airflow of convection to optimize jerky drying efficiency. This method enhances moisture removal while preserving texture and flavor, outperforming traditional convection or infrared dehydrators used alone.

Enhanced surface moisture migration

Infrared dehydrators enhance surface moisture migration by using radiant heat that penetrates jerky fibers, accelerating water removal and resulting in faster drying times compared to convection dehydrators, which rely on hot air circulation. This targeted heat transfer in infrared units improves moisture diffusion efficiency on jerky surfaces, producing a more uniform texture and reducing the risk of uneven drying or case hardening.

IR-glass emitter panels

Infrared (IR) glass emitter panels in dehydrators provide consistent and deep heat penetration, accelerating moisture removal in jerky compared to convection dehydrators that rely on hot air circulation. This focused infrared energy preserves the meat's texture and flavor more effectively while reducing drying times and energy consumption.

Uniform hot air cycling

Convection dehydrators use uniform hot air cycling to evenly remove moisture from jerky, ensuring consistent texture and flavor throughout the strips. Infrared dehydrators, while efficient in heat penetration, may cause uneven drying due to localized hotspots, potentially compromising the jerky's quality and shelf life.

Photothermal jerky drying

Convection dehydrators use hot air circulation to remove moisture from jerky, providing consistent drying but often requiring longer times and higher energy consumption. Infrared dehydrators utilize photothermal technology to penetrate meat fibers, accelerating moisture evaporation and preserving flavor with enhanced drying efficiency and uniformity in jerky production.

Convection dehydrator vs Infrared dehydrator for jerky. Infographic

cookingdiff.com

cookingdiff.com