Sun drying vegetables relies on natural sunlight and airflow, offering an energy-efficient and cost-effective method but often results in inconsistent moisture removal and potential contamination. Infrared drying uses targeted infrared radiation to rapidly penetrate and evaporate moisture, ensuring uniform drying and better preservation of nutrients and color. This technology provides faster processing times and enhanced product quality compared to traditional sun drying.

Table of Comparison

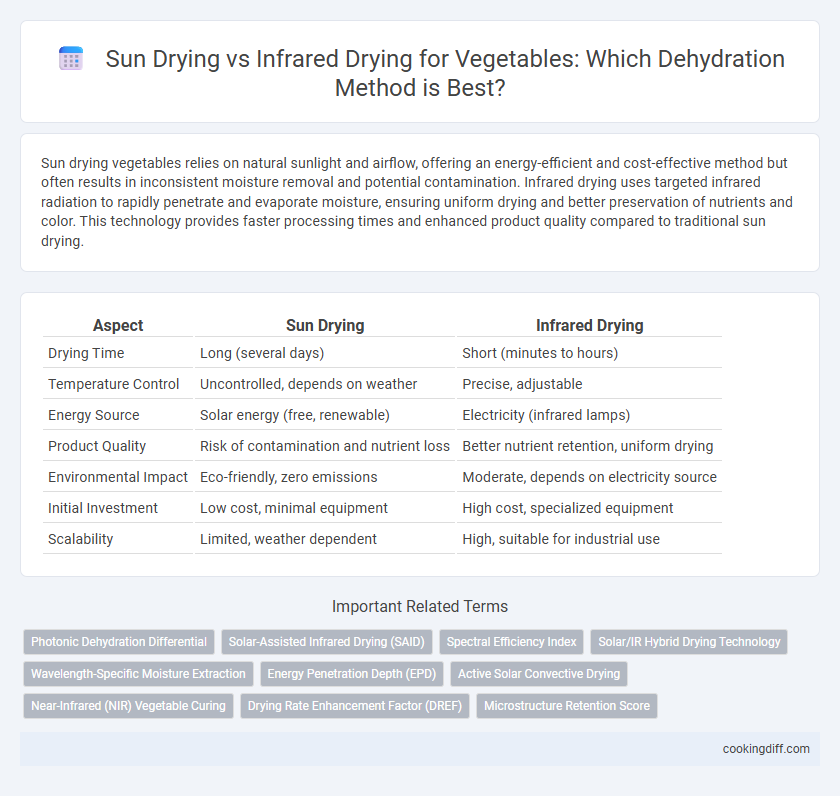

| Aspect | Sun Drying | Infrared Drying |

|---|---|---|

| Drying Time | Long (several days) | Short (minutes to hours) |

| Temperature Control | Uncontrolled, depends on weather | Precise, adjustable |

| Energy Source | Solar energy (free, renewable) | Electricity (infrared lamps) |

| Product Quality | Risk of contamination and nutrient loss | Better nutrient retention, uniform drying |

| Environmental Impact | Eco-friendly, zero emissions | Moderate, depends on electricity source |

| Initial Investment | Low cost, minimal equipment | High cost, specialized equipment |

| Scalability | Limited, weather dependent | High, suitable for industrial use |

Introduction to Vegetable Dehydration Methods

Vegetable dehydration methods significantly influence the quality, nutrient retention, and shelf life of dried produce. Sun drying and infrared drying represent two primary techniques with distinct mechanisms and efficiency levels.

- Sun Drying - Utilizes natural sunlight to remove moisture but is weather-dependent and slower.

- Infrared Drying - Employs infrared radiation for rapid, uniform moisture removal, preserving color and nutrients better.

- Quality Impact - Infrared drying generally enhances preservation of vitamins and texture compared to traditional sun drying.

Overview of Sun Drying for Vegetables

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Sun Drying | Traditional dehydration method using natural sunlight to remove moisture from vegetables. | Cost-effective, environmentally friendly, and requires minimal equipment. | Slow drying time, exposure to contaminants, weather-dependent, and inconsistent quality control. |

Fundamentals of Infrared Drying Technology

Infrared drying technology utilizes electromagnetic radiation to penetrate vegetable surfaces, causing water molecules to vibrate and evaporate efficiently. This method offers faster drying rates and better nutrient retention compared to traditional sun drying, which relies on ambient conditions and exposes produce to contamination risks. The controlled environment of infrared drying reduces microbial growth and preserves color and texture, making it a superior choice for dehydrating vegetables.

Efficiency Comparison: Sun Drying vs Infrared Drying

Sun drying vegetables relies on natural sunlight and ambient conditions, which can result in longer drying times and inconsistent moisture removal. Infrared drying uses electromagnetic radiation to rapidly heat and dehydrate vegetables, significantly reducing processing time and improving energy efficiency.

Sun drying's dependency on weather limits its efficiency and can lead to nutrient loss and contamination risks. Infrared drying operates under controlled conditions, providing uniform heat distribution and preserving the vegetables' nutritional quality. This method enhances throughput and reduces overall energy consumption compared to traditional sun drying techniques.

Impact on Nutritional Value and Quality

Sun drying preserves vitamins A and C moderately but often results in uneven drying and nutrient loss due to prolonged exposure to environmental factors. Infrared drying offers faster dehydration, retaining higher levels of antioxidants and essential nutrients by minimizing heat exposure time. This method also improves texture and color retention, ensuring better overall quality in dried vegetables compared to traditional sun drying.

Energy Consumption and Cost Analysis

Sun drying vegetables leverages natural solar energy, resulting in minimal operational costs and zero energy consumption but requires longer drying times and is weather-dependent. Infrared drying consumes approximately 30-50% less energy than conventional hot air drying methods, offering a more controlled environment with faster drying rates.

While infrared drying involves higher initial equipment costs, the reduction in drying time and energy use translates to lower long-term operational expenses. Sun drying incurs negligible upfront costs but may lead to inconsistent product quality and higher labor expenses due to extended drying durations.

Safety and Hygiene Considerations

Sun drying exposes vegetables to environmental contaminants and inconsistent temperatures, increasing the risk of microbial growth. Infrared drying offers a controlled environment, reducing contamination risks and enhancing hygiene.

- Sun drying contamination risk - Vegetables are exposed to dust, insects, and airborne pathogens during sun drying.

- Infrared drying temperature control - Infrared methods ensure uniform heating, minimizing conditions favorable for bacterial growth.

- Hygienic processing - Infrared drying occurs in enclosed chambers, preventing external contamination and ensuring food safety.

Suitability for Different Types of Vegetables

Sun drying is highly suitable for hardy vegetables like tomatoes, peppers, and okra due to its low cost and natural preservation process, though it requires prolonged exposure to sunlight and favorable weather conditions. Infrared drying excels with leafy greens and delicate vegetables, offering faster moisture removal while preserving texture and nutritional content effectively.

The choice between sun drying and infrared drying depends on vegetable thickness, moisture content, and sensitivity to heat; infrared drying provides more uniform dehydration suitable for vegetables prone to browning or loss of nutrients under direct sun. Sun drying is preferable for robust vegetables that can withstand extended drying times without significant quality degradation, making it more cost-effective for large, thick produce batches.

Environmental Impact and Sustainability

How do sun drying and infrared drying compare in terms of environmental impact and sustainability for vegetables? Sun drying utilizes natural sunlight, requiring no electricity and generating zero emissions, making it highly sustainable but reliant on weather conditions and longer drying times. Infrared drying consumes energy but offers faster processing with more controlled conditions, potentially reducing food waste and energy usage if powered by renewable sources.

Related Important Terms

Photonic Dehydration Differential

Sun drying utilizes natural solar radiation to remove moisture from vegetables, relying primarily on ultraviolet and visible light wavelengths, which leads to slower dehydration and potential nutrient degradation. Infrared drying employs controlled infrared radiation that penetrates deeper into vegetable tissues, enhancing water evaporation rates and preserving nutritional quality through more efficient photonic energy absorption.

Solar-Assisted Infrared Drying (SAID)

Solar-Assisted Infrared Drying (SAID) combines the energy efficiency of solar drying with the rapid heat transfer of infrared radiation, significantly reducing drying time while preserving the nutritional quality and color of vegetables. Compared to traditional sun drying, SAID offers enhanced control over temperature and moisture removal, minimizing microbial contamination and improving product safety.

Spectral Efficiency Index

Sun drying of vegetables relies primarily on broad-spectrum solar radiation, which often results in lower Spectral Efficiency Index (SEI) due to inconsistent intensity and wavelength distribution, whereas infrared drying utilizes targeted wavelengths that enhance SEI by efficiently penetrating cellular structures to accelerate moisture removal and preserve nutritional quality. Infrared drying systems demonstrate superior spectral efficiency by emitting in the optimal infrared range (700-1400 nm), maximizing energy absorption and reducing drying time compared to the variable and less intense solar spectrum in traditional sun drying.

Solar/IR Hybrid Drying Technology

Solar/Infrared hybrid drying technology combines the natural, energy-efficient process of sun drying with the rapid, consistent heat of infrared drying, significantly reducing dehydration time while preserving nutrients and color in vegetables. This innovative method enhances moisture removal rates and microbial safety compared to traditional sun drying, offering a sustainable and effective solution for vegetable preservation.

Wavelength-Specific Moisture Extraction

Sun drying utilizes broad-spectrum sunlight primarily in the 300-2500 nm range, allowing natural evaporation but with slower moisture extraction and higher risk of contamination. Infrared drying employs targeted wavelengths between 700-1400 nm, enhancing penetration and accelerating moisture removal while preserving vegetable texture and nutrients more efficiently.

Energy Penetration Depth (EPD)

Infrared drying offers a greater Energy Penetration Depth (EPD) compared to sun drying, enabling more uniform and efficient moisture removal from vegetables. This deeper energy absorption reduces drying time and preserves nutritional quality by minimizing surface overheating.

Active Solar Convective Drying

Sun drying of vegetables relies on natural sunlight and airflow, offering a cost-effective but slower dehydration process prone to contamination and inconsistent drying rates. Infrared drying, particularly through active solar convective drying systems, combines infrared radiation with forced convection to enhance moisture removal, improve drying uniformity, and reduce processing time while maintaining nutrient retention.

Near-Infrared (NIR) Vegetable Curing

Near-Infrared (NIR) vegetable curing offers faster drying rates and better nutrient retention compared to traditional sun drying, utilizing wavelengths between 0.74 to 1.4 micrometers to penetrate and heat vegetables efficiently. This method reduces microbial growth and preserves color and texture, making it a superior choice for industrial-scale vegetable dehydration over conventional sun drying.

Drying Rate Enhancement Factor (DREF)

Sun drying of vegetables typically results in a lower Drying Rate Enhancement Factor (DREF) compared to infrared drying, as the latter provides controlled and uniform heat that accelerates moisture evaporation. Infrared drying enhances DREF by up to 3 times relative to sun drying, reducing dehydration time and improving process efficiency in vegetable preservation.

Sun drying vs Infrared drying for vegetables. Infographic

cookingdiff.com

cookingdiff.com