A fine mesh liner offers excellent airflow and prevents small food pieces from falling through the trays, making it ideal for dehydrating delicate items like herbs and fruit slices. Paraflexx sheets provide a non-stick surface and are easy to clean, perfect for drying sticky or wet foods such as jerky and fruit leather. Choosing between the two depends on the specific dehydrating needs, with fine mesh liners favoring ventilation and Paraflexx sheets emphasizing convenience and non-stick properties.

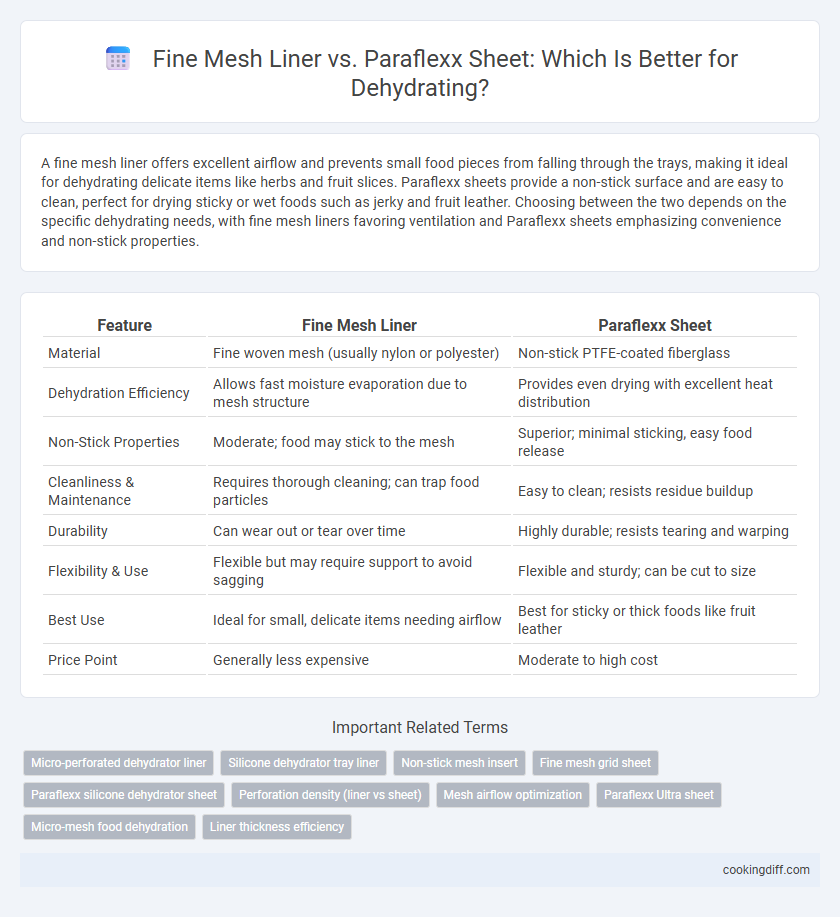

Table of Comparison

| Feature | Fine Mesh Liner | Paraflexx Sheet |

|---|---|---|

| Material | Fine woven mesh (usually nylon or polyester) | Non-stick PTFE-coated fiberglass |

| Dehydration Efficiency | Allows fast moisture evaporation due to mesh structure | Provides even drying with excellent heat distribution |

| Non-Stick Properties | Moderate; food may stick to the mesh | Superior; minimal sticking, easy food release |

| Cleanliness & Maintenance | Requires thorough cleaning; can trap food particles | Easy to clean; resists residue buildup |

| Durability | Can wear out or tear over time | Highly durable; resists tearing and warping |

| Flexibility & Use | Flexible but may require support to avoid sagging | Flexible and sturdy; can be cut to size |

| Best Use | Ideal for small, delicate items needing airflow | Best for sticky or thick foods like fruit leather |

| Price Point | Generally less expensive | Moderate to high cost |

Introduction to Dehydrator Liners: Fine Mesh vs. Paraflexx

Dehydrator liners enhance the drying process by preventing small food particles from falling through the trays, with Fine Mesh liners offering a tightly woven fabric that allows excellent airflow while maintaining food integrity. Paraflexx sheets provide a non-stick, flexible surface that simplifies cleaning and improves durability.

Fine Mesh liners are ideal for dehydrating small or delicate items like herbs and finely chopped fruits, ensuring maximum airflow and even drying. Paraflexx sheets excel when drying sticky or chewy foods, preventing sticking and tearing. Both options significantly improve hygiene and extend the lifespan of dehydrator trays, making them essential accessories for efficient food preservation.

Material Composition: Fine Mesh Liner vs. Paraflexx Sheet

The Fine Mesh Liner is made from a tightly woven nylon mesh that allows for efficient air circulation while preventing small pieces from falling through. The Paraflexx Sheet consists of a flexible, non-stick Teflon-coated fiberglass mesh designed to withstand high dehydration temperatures and resist sticking.

- Fine Mesh Liner Composition - Constructed from durable nylon, offering breathability and resistance to mold during dehydration.

- Paraflexx Sheet Composition - Made with fiberglass base and Teflon coating, providing non-stick properties and higher heat tolerance.

- Material Impact on Drying - Nylon allows faster moisture removal due to fine pores, while Teflon coating reduces food adhesion for easier cleanup.

The choice between them depends on specific dehydrating needs regarding airflow efficiency and ease of maintenance.

Suitability for Different Foods: Fruits, Veggies, and Beyond

Fine mesh liners offer superior airflow, making them ideal for dehydrating delicate fruits and herbs without losing texture or flavor. Paraflexx sheets provide a non-stick surface perfect for sticky or wet foods like fruit leathers, purees, and vegetables with high moisture content. Both options enhance dehydration efficiency but cater to different food types based on texture and moisture levels.

Non-Stick Performance Compared: Which Prevents Sticking Better?

The Paraflexx sheet exhibits superior non-stick performance compared to fine mesh liners, effectively preventing food from sticking during dehydrating. Its smooth, silicone-coated surface ensures easy release of delicate items like fruit leather or thin slices without tearing or residue.

Fine mesh liners, while breathable and allowing excellent airflow, often cause sticky foods to adhere due to their textured surface. This texture can complicate the removal process, making Paraflexx sheets the preferred choice for maintaining product integrity and simplifying cleanup.

Airflow and Drying Efficiency: Fine Mesh or Paraflexx?

Fine mesh liners provide superior airflow due to their tightly woven structure, allowing moisture to evaporate quickly and evenly during dehydration. This increased airflow enhances drying efficiency, particularly for small or delicate foods that require consistent drying conditions.

Paraflexx sheets offer a non-stick surface with moderate airflow, making them suitable for sticky or thin items that might otherwise fall through fine mesh. While airflow is slightly reduced compared to fine mesh liners, Paraflexx sheets maintain effective drying by balancing airflow with a protective barrier for delicate foods.

Ease of Cleaning and Maintenance

Which is easier to clean and maintain, a fine mesh liner or a Paraflexx sheet when dehydrating? Fine mesh liners often require more effort to clean due to trapped food particles within the mesh weave. Paraflexx sheets, made from flexible silicone, are non-stick and dishwasher safe, making them simpler to clean and maintain over time.

Durability and Longevity in Frequent Use

Fine mesh liners offer moderate durability but may wear out faster with frequent use due to their delicate mesh structure. Paraflexx sheets, composed of durable silicone, provide superior longevity and resistance to frequent dehydrating cycles.

- Fine Mesh Liner - Constructed with thin, delicate fibers that can fray or tear after repeated use.

- Paraflexx Sheet - Made from high-quality silicone resistant to cracking, maintaining integrity over time.

- Maintenance - Paraflexx sheets are easier to clean and reuse without degradation, extending their lifespan in daily dehydrating tasks.

Reusability and Environmental Impact

Fine mesh liners offer limited reusability and may degrade faster, leading to more frequent replacements compared to Paraflexx sheets, which are highly durable and designed for long-term use. Choosing reusable Paraflexx sheets reduces waste and environmental impact by minimizing single-use product disposal.

- Fine mesh liners have shorter lifespan - Frequent replacement increases waste and environmental footprint.

- Paraflexx sheets provide extended durability - Enables multiple dehydration cycles with consistent performance.

- Paraflexx reduces plastic waste - Supports sustainable food preservation with less environmental damage.

Cost Comparison: Upfront and Long-Term Value

| Fine Mesh Liner | Lower upfront cost, typically under $15, making it budget-friendly for occasional dehydrating. Durable design allows multiple uses, offering moderate long-term value. Requires gentle handling to maintain mesh integrity, potentially leading to replacement costs over time. |

| Paraflexx Sheet | Higher initial investment, often around $30-$40, reflecting premium materials and construction. Exceptionally durable with resistance to cracking and warping, providing superior long-term cost efficiency. Easy to clean and maintain, reducing replacement frequency and overall expenses. |

Related Important Terms

Micro-perforated dehydrator liner

Micro-perforated dehydrator liners, such as fine mesh liners, provide superior airflow and even drying, preventing small food particles from falling through while enhancing dehydration efficiency. Compared to Paraflexx sheets, fine mesh liners offer greater breathability and flexibility, ideal for delicate or small food items requiring consistent moisture removal.

Silicone dehydrator tray liner

Silicone dehydrator tray liners like the Fine Mesh Liner offer superior heat resistance and flexibility compared to Paraflexx sheets, ensuring even airflow and easy food release during dehydrating. These liners provide a non-stick surface ideal for drying small or sticky foods without contamination or residue buildup.

Non-stick mesh insert

A fine mesh liner offers a superior non-stick surface for dehydrating delicate foods by allowing optimal airflow and easy release without residue. Paraflexx sheets provide a versatile, reusable non-stick barrier that resists sticking and withstands high temperatures, ideal for consistent dehydration results.

Fine mesh grid sheet

Fine mesh liner sheets enhance dehydration efficiency by allowing optimal airflow and preventing smaller food particles from falling through, making them ideal for drying herbs, vegetables, and jerky. Their durable, non-stick surfaces ensure easy cleanup and consistent moisture removal compared to Paraflexx sheets, which are better suited for thicker or wetter foods.

Paraflexx silicone dehydrator sheet

Paraflexx silicone dehydrator sheets provide superior flexibility and non-stick properties compared to fine mesh liners, ensuring even dehydration and easy removal of delicate foods like fruits and herbs. Their durable, food-grade silicone material withstands high temperatures without tearing, making them ideal for long-term use in commercial and home dehydrators.

Perforation density (liner vs sheet)

Fine mesh liners typically feature a higher perforation density with numerous small holes per square inch, enhancing airflow and even dehydration compared to Paraflexx sheets, which have larger, fewer perforations designed for durability and easy food release. The increased perforation density in fine mesh liners accelerates moisture removal and reduces drying time, optimizing efficiency in dehydrating delicate fruits and vegetables.

Mesh airflow optimization

Fine mesh liners provide superior airflow optimization during dehydrating by allowing consistent air circulation while preventing smaller food particles from falling through, enhancing dehydration efficiency. Paraflexx sheets, made from flexible silicone, offer moderate airflow but prioritize non-stick surfaces and easy cleaning over maximum air permeability, potentially reducing drying speed compared to fine mesh liners.

Paraflexx Ultra sheet

Paraflexx Ultra sheet offers superior flexibility, durability, and easy cleaning compared to fine mesh liners, making it ideal for dehydrating sticky or delicate foods without residue buildup. Its non-stick, heat-resistant silicone material promotes even air circulation and faster drying times, enhancing efficiency in food dehydration processes.

Micro-mesh food dehydration

Fine mesh liners for dehydrating offer superior airflow and prevent small food particles from falling through, making them ideal for delicate items like herbs and fruit slices; micro-mesh technology enhances moisture evaporation while maintaining food integrity. Paraflexx sheets, constructed from durable silicone mesh, provide excellent non-stick surfaces and easy cleanup but may slightly reduce airflow compared to fine mesh liners, potentially affecting drying speed and uniformity.

Fine mesh liner vs Paraflexx sheet for dehydrating. Infographic

cookingdiff.com

cookingdiff.com