Powder dehydration involves removing moisture by converting liquids into fine, dry particles, offering longer shelf life and easier storage while retaining nutrient content. Foam-mat dehydration aerates the product before drying, resulting in faster moisture removal and improved flavor and color retention due to the porous structure of the foam. Both methods are effective, but foam-mat dehydration is especially beneficial for heat-sensitive materials needing preservation of texture and nutrients.

Table of Comparison

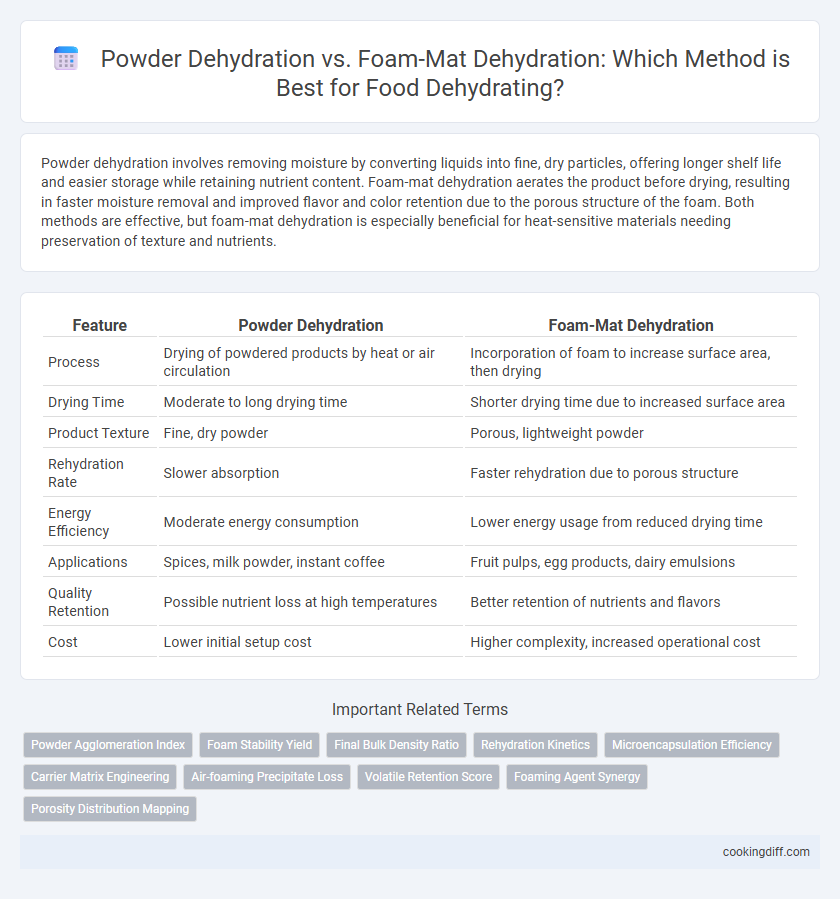

| Feature | Powder Dehydration | Foam-Mat Dehydration |

|---|---|---|

| Process | Drying of powdered products by heat or air circulation | Incorporation of foam to increase surface area, then drying |

| Drying Time | Moderate to long drying time | Shorter drying time due to increased surface area |

| Product Texture | Fine, dry powder | Porous, lightweight powder |

| Rehydration Rate | Slower absorption | Faster rehydration due to porous structure |

| Energy Efficiency | Moderate energy consumption | Lower energy usage from reduced drying time |

| Applications | Spices, milk powder, instant coffee | Fruit pulps, egg products, dairy emulsions |

| Quality Retention | Possible nutrient loss at high temperatures | Better retention of nutrients and flavors |

| Cost | Lower initial setup cost | Higher complexity, increased operational cost |

Introduction to Dehydration Methods

Powder dehydration involves removing moisture to produce fine, dry particles, enhancing shelf life and facilitating easy rehydration. Foam-mat dehydration creates a porous foam structure before drying, resulting in fast moisture removal and improved retention of color and nutrients.

Powder dehydration is widely used for products like milk and spices due to its efficiency in reducing water content to very low levels. Foam-mat dehydration preserves heat-sensitive compounds better by minimizing drying time and temperature exposure. Both methods optimize moisture removal but differ in texture, drying rate, and nutrient preservation capabilities.

Understanding Powder Dehydration

Powder dehydration involves removing moisture from liquid products to produce a dry, powdered form that offers extended shelf life and ease of transportation. This method utilizes techniques such as spray drying and freeze drying to preserve nutritional quality and flavor while minimizing microbial growth. In comparison to foam-mat dehydration, powder dehydration provides a more concentrated, stable product with lower moisture content and longer preservation capabilities.

What is Foam-Mat Dehydration?

Foam-mat dehydration is a technique where food liquids are whipped into a stable foam using foaming agents before drying, resulting in faster drying rates and porous end products. This method retains more nutrients and flavor compared to traditional powder dehydration due to reduced thermal damage.

Unlike powder dehydration, which involves drying powders directly and often sacrifices sensory qualities, foam-mat dehydration produces powders with better rehydration properties and texture. This technology is widely used for juices, purees, and heat-sensitive food products requiring high-quality final powders.

Process Steps: Powder vs Foam-Mat Dehydration

| Process Step | Powder Dehydration | Foam-Mat Dehydration |

|---|---|---|

| Preparation | Raw material is cleaned, crushed, and homogenized into a slurry or liquid form. | Raw material is whipped with foaming agents to create stable foam before spreading into thin mats. |

| Drying | Slurry is sprayed or atomized into hot air chamber for rapid moisture removal, forming powder particles. | Foam mats are dried on trays or conveyors at controlled temperature to preserve structure and nutrients. |

| Post-processing | Dried powder is collected, sieved, and packed under controlled humidity to prevent caking. | Dried foam sheets are ground if needed and packaged to maintain low moisture content and texture. |

Equipment Needed for Each Method

What equipment is required for powder dehydration compared to foam-mat dehydration? Powder dehydration typically demands spray dryers or vacuum dryers to efficiently remove moisture and produce fine powder particles. Foam-mat dehydration requires equipment such as foaming agents, spreaders, and hot air dryers to maintain foam structure and achieve uniform drying.

Efficiency and Drying Time Comparison

Powder dehydration typically requires longer drying times due to the dense structure of powders, which limits moisture removal efficiency. In contrast, foam-mat dehydration enhances drying speed by increasing the surface area and porosity, allowing faster moisture escape. Efficiency in foam-mat drying often exceeds powder dehydration, making it ideal for heat-sensitive products requiring rapid processing.

Nutritional Retention: Powder vs Foam-Mat

Powder dehydration typically results in higher nutrient concentration due to the removal of water content, preserving vitamins and minerals more effectively than Foam-mat dehydration. Foam-mat dehydration, while faster, may cause greater nutrient degradation due to increased exposure to air and heat during the process.

- Powder dehydration retains essential vitamins - This method minimizes nutrient loss by efficiently removing moisture while maintaining the food's nutrient profile.

- Foam-mat dehydration accelerates drying time - The foaming process introduces air bubbles, which can increase oxidation and reduce vitamin content.

- Nutritional retention varies by method - Powder dehydration is often preferred for maximum preservation of antioxidants, proteins, and minerals compared to foam-mat techniques.

Texture and Quality of Dehydrated Products

Powder dehydration typically results in a fine, uniform texture but can cause denser, less porous products. Foam-mat dehydration maintains a lighter, more porous texture, preserving sensory qualities closer to fresh products.

- Texture Retention - Foam-mat dehydration preserves cellular structure better, leading to improved rehydration and mouthfeel.

- Quality Impact - Powder dehydration may cause nutrient loss due to higher drying temperatures and compaction.

- Product Appearance - Foam-mat dehydrated products exhibit less shrinkage and color degradation compared to powder dehydration.

Best Applications for Each Dehydration Method

Powder dehydration excels in preserving heat-sensitive nutrients, making it ideal for fruit and vegetable powders. Foam-mat dehydration is best suited for liquid or semi-liquid foods, enhancing drying efficiency and product texture.

- Powder dehydration for fruit powders - Maintains color and nutritional content effectively.

- Foam-mat dehydration for dairy products - Improves drying rate while retaining creaminess.

- Powder dehydration for spices - Ensures long shelf life and flavor retention.

Each dehydration method is optimized for specific food types to maximize quality and efficiency.

Related Important Terms

Powder Agglomeration Index

Powder dehydration typically results in a higher Powder Agglomeration Index due to particle size enlargement during milling and drying, affecting flowability and solubility. Foam-mat dehydration creates a lower Powder Agglomeration Index by forming uniform, porous structures that reduce particle clumping and enhance rehydration properties.

Foam Stability Yield

Foam-mat dehydration offers superior foam stability yield compared to powder dehydration, ensuring better retention of product texture and nutritional quality during drying. Enhanced foam stability in foam-mat dehydration minimizes shrinkage and oxidation, resulting in higher-quality dehydrated products with prolonged shelf life.

Final Bulk Density Ratio

Powder dehydration typically results in a higher final bulk density ratio due to the compact nature of the powdered particles, enhancing storage efficiency. Foam-mat dehydration produces a lower bulk density ratio by incorporating air into the foam structure, yielding a lighter, porous product ideal for quick rehydration.

Rehydration Kinetics

Powder dehydration typically results in slower rehydration kinetics due to reduced surface area and denser particle structure, whereas foam-mat dehydration enhances rehydration rates by creating a porous matrix that facilitates rapid water absorption. The foam-mat technique preserves cellular integrity better, leading to improved water diffusion and quicker restoration of original texture upon rehydration.

Microencapsulation Efficiency

Powder dehydration demonstrates higher microencapsulation efficiency due to its ability to form dense, uniform particle coatings that effectively protect sensitive core materials from oxidation and moisture. In contrast, foam-mat dehydration offers lower encapsulation efficiency because the porous foam structure can lead to increased permeability and reduced barrier properties around the encapsulated compounds.

Carrier Matrix Engineering

Carrier matrix engineering in powder dehydration enables precise control over particle size and moisture retention, optimizing nutrient preservation and rehydration capacity. Foam-mat dehydration leverages a cellular carrier matrix that enhances drying efficiency and surface area exposure, resulting in improved texture and faster drying rates compared to conventional powder dehydration methods.

Air-foaming Precipitate Loss

Powder dehydration often results in higher air-foaming precipitate loss due to extensive particle agglomeration and moisture entrapment during drying. Foam-mat dehydration minimizes this loss by creating a stable foam matrix that enhances moisture removal while preserving product integrity and reducing particulate aggregation.

Volatile Retention Score

Powder dehydration methods typically achieve lower Volatile Retention Scores due to increased exposure to heat and air, leading to greater loss of aroma and flavor compounds. Foam-mat dehydration maintains higher Volatile Retention Scores by creating a protective foam matrix that reduces oxidation and preserves volatile bioactive components more effectively.

Foaming Agent Synergy

Foam-mat dehydration leverages the synergy of foaming agents like egg albumin and methylcellulose to create stable, uniform foams that enhance moisture evaporation and preserve nutrient content more effectively than traditional powder dehydration. This combination improves drying rates and product rehydration quality by facilitating a porous structure that powder dehydration cannot achieve.

Powder dehydration vs Foam-mat dehydration for dehydrating. Infographic

cookingdiff.com

cookingdiff.com