When dehydrating pet food, an oven provides a consistent heat source but can be less energy-efficient and may require constant monitoring to prevent overheating. Food Cyclers are specifically designed for food dehydration, offering precise temperature control and faster drying times, making them safer and more effective for maintaining nutrient quality. Choosing a Food Cycler ensures better preservation of vitamins and enzymes essential for pet health compared to traditional oven drying.

Table of Comparison

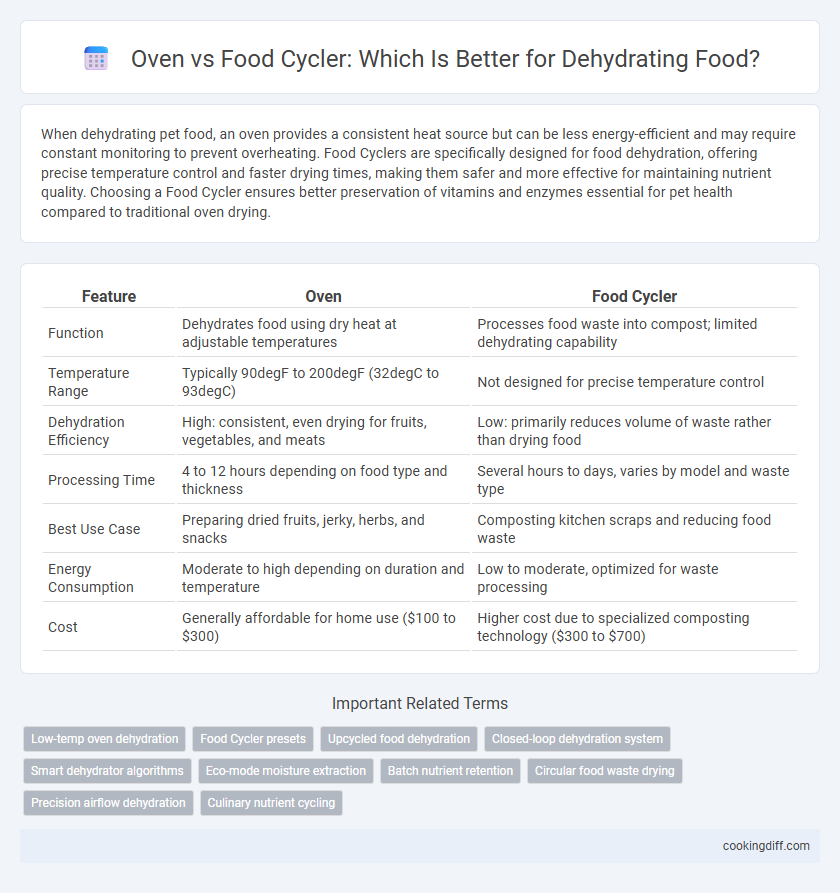

| Feature | Oven | Food Cycler |

|---|---|---|

| Function | Dehydrates food using dry heat at adjustable temperatures | Processes food waste into compost; limited dehydrating capability |

| Temperature Range | Typically 90degF to 200degF (32degC to 93degC) | Not designed for precise temperature control |

| Dehydration Efficiency | High: consistent, even drying for fruits, vegetables, and meats | Low: primarily reduces volume of waste rather than drying food |

| Processing Time | 4 to 12 hours depending on food type and thickness | Several hours to days, varies by model and waste type |

| Best Use Case | Preparing dried fruits, jerky, herbs, and snacks | Composting kitchen scraps and reducing food waste |

| Energy Consumption | Moderate to high depending on duration and temperature | Low to moderate, optimized for waste processing |

| Cost | Generally affordable for home use ($100 to $300) | Higher cost due to specialized composting technology ($300 to $700) |

Introduction to Dehydrating: Oven vs Food Cycler

Dehydrating food preserves nutrients and extends shelf life by removing moisture. Ovens are a common tool for dehydrating, offering adjustable temperature settings but often lack precise humidity control. Food Cyclers provide a compact, energy-efficient alternative specifically designed for dehydration, streamlining the process with controlled heat and airflow.

How Ovens Dehydrate Food: Method and Efficiency

Ovens dehydrate food by circulating heated air at temperatures typically between 120degF and 200degF, removing moisture through evaporation. This method requires careful temperature control to prevent cooking or burning, but can be less energy-efficient than specialized dehydrators like the Food Cycler.

- Heat Distribution - Ovens use convection to spread hot air evenly, but can have uneven drying spots depending on oven design and airflow.

- Temperature Control - Precise temperature settings are crucial to avoid overheating that cooks rather than dehydrates food.

- Energy Efficiency - Ovens generally consume more energy and take longer to dehydrate food compared to compact, purpose-built devices like the Food Cycler.

Understanding Food Cycler Technology for Dehydration

Food Cycler technology utilizes a compartmentalized system combining heating, grinding, and aeration to efficiently reduce food waste and dehydrate organic matter. Unlike traditional ovens that apply consistent heat over hours, Food Cyclers accelerate moisture removal through controlled airflow and mechanical shredding.

This innovative dehydration process preserves nutrient content and minimizes energy consumption compared to conventional oven drying methods. Food Cyclers also reduce odors and volume more effectively, making them suitable for compact kitchen environments and sustainable waste management.

Energy Consumption Comparison: Oven vs Food Cycler

| Appliance | Energy Consumption (kWh per hour) | Efficiency in Dehydrating |

|---|---|---|

| Oven | 2.0 - 3.0 | Higher heat output but less energy efficient for prolonged dehydration |

| Food Cycler | 0.5 - 1.0 | Optimized low-energy use specifically designed for efficient dehydration |

Dehydration Time: Which is Faster?

The Food Cycler drastically reduces dehydration time by using advanced technology to break down food waste rapidly, typically completing the process within 3 to 4 hours. In contrast, traditional ovens require a longer duration, often taking 6 to 12 hours depending on the temperature and food type.

Ovens operate at lower temperatures to preserve nutrients, which slows dehydration, whereas Food Cyclers optimize heat and airflow for maximum efficiency. For users prioritizing speed, the Food Cycler offers a significant advantage in dehydration performance over standard ovens.

Quality and Consistency of Dehydrated Foods

The Food Cycler uses precise temperature control and moisture removal technology, resulting in higher quality and more consistent dehydration compared to a conventional oven. Ovens often produce uneven drying due to fluctuating heat distribution, which can compromise texture and flavor. Consistently dried foods from a Food Cycler retain better nutrients, color, and overall quality throughout multiple batches.

Capacity and Batch Size: Pros and Cons

Which option offers better capacity and batch size for dehydrating, oven or food cycler? Ovens typically provide larger capacity and can handle bigger batch sizes, making them suitable for bulk dehydrating projects. Food cyclers have smaller chambers and limited batch sizes, best for occasional or small-scale dehydrating needs.

Ease of Use and Maintenance

Compared to a traditional oven, a food cycler offers greater ease of use with preset dehydration cycles and minimal temperature adjustments. Maintenance is simpler in food cyclers due to removable trays and dishwasher-safe parts, whereas ovens require manual cleaning and monitoring.

- Preset Settings - Food cyclers feature automated dehydration programs, reducing user input.

- Tray Design - Food cyclers have stackable, easy-to-clean trays that streamline upkeep.

- Oven Complexity - Ovens need constant temperature control and periodic deep cleaning.

Food cyclers deliver a more user-friendly experience and lower maintenance than conventional ovens for dehydrating tasks.

Cost Analysis: Upfront and Ongoing Expenses

Ovens generally require a higher initial investment but offer versatility beyond dehydrating, while Food Cyclers present a more affordable upfront cost with specialized functionality. Ongoing energy expenses tend to be lower for Food Cyclers due to their compact size and efficiency compared to traditional ovens.

- Upfront cost - Ovens typically range from $100 to $500, whereas Food Cyclers cost between $300 and $400.

- Energy consumption - Food Cyclers consume less power, reducing electricity bills during frequent use.

- Maintenance expenses - Ovens may incur higher long-term maintenance costs due to component wear and multi-function use.

Related Important Terms

Low-temp oven dehydration

Low-temp oven dehydration typically operates at temperatures between 100degF and 150degF, making it suitable for preserving nutrients and enzymes while effectively removing moisture from fruits, vegetables, and herbs. Compared to Food Cycler devices, which use grinding and accelerated decomposition, low-temp ovens provide a more traditional, controlled drying process ideal for long-term storage without altering food texture or flavor.

Food Cycler presets

Food Cyclers feature specialized presets designed to optimize dehydration by precisely controlling temperature and time for various foods, ensuring consistent results without the need for manual adjustments. Unlike traditional ovens, Food Cyclers utilize advanced dehydration cycles that preserve nutrients and flavors while significantly reducing energy consumption.

Upcycled food dehydration

Oven dehydration uses consistent heat to remove moisture from upcycled food, making it ideal for creating shelf-stable snacks with controlled texture, while the Food Cycler combines grinding, dehydrating, and sanitizing in a compact unit suited for small-batch upcycled food processing and waste reduction. Choosing between the two depends on scale and purpose, as ovens excel in volume and uniform drying, whereas Food Cyclers promote eco-friendly upcycling with minimal energy consumption and kitchen waste conversion.

Closed-loop dehydration system

Oven dehydration relies on open-air heat circulation that can lead to uneven drying and energy loss, while the Food Cycler uses a closed-loop dehydration system that recycles moisture and heat, ensuring consistent results and improved energy efficiency. This closed-loop design reduces environmental impact by minimizing water vapor release and conserving heat within the appliance.

Smart dehydrator algorithms

Oven dehydrators rely on consistent heat settings and manual timing, lacking advanced control over moisture levels, whereas Food Cycler devices employ smart dehydrator algorithms that dynamically adjust temperature and drying cycles to optimize nutrient retention and reduce dehydration time. These intelligent algorithms monitor humidity and airflow, ensuring precise drying and improved food texture compared to conventional oven methods.

Eco-mode moisture extraction

Oven dehydration uses sustained dry heat to remove moisture, consuming significant energy without tailored moisture extraction, whereas Food Cycler's Eco-mode employs low-energy, accelerated dehydration cycles designed to optimize moisture extraction while conserving power. The Food Cycler's advanced moisture sensors and controlled airflow reduce overall energy consumption by up to 60% compared to traditional oven drying methods.

Batch nutrient retention

Ovens typically expose foods to prolonged high heat, causing significant nutrient loss during dehydration, while the Food Cycler uses lower temperatures and controlled airflow to better preserve vitamins and minerals. Studies show batch nutrient retention is higher in Food Cyclers, maintaining more antioxidants, enzymes, and essential nutrients compared to conventional ovens.

Circular food waste drying

Oven dehydrating uses consistent heat to remove moisture from food, but often consumes more energy and lacks precise temperature control compared to a Food Cycler, which employs rapid, low-temperature drying combined with microbial action to efficiently convert food waste into nutrient-rich compost. Circular food waste drying with a Food Cycler supports sustainable waste management by reducing landfill contributions and accelerating organic recycling within compact kitchen-friendly units.

Precision airflow dehydration

Oven dehydration offers high heat but often lacks precision airflow control, leading to uneven moisture removal in foods. Food Cyclers utilize advanced precision airflow technology to ensure consistent, efficient dehydration by evenly circulating air, preserving nutrients and texture more effectively.

Oven vs Food Cycler for dehydrating. Infographic

cookingdiff.com

cookingdiff.com