Sun drying is a traditional, cost-effective method that uses natural heat and airflow to remove moisture from fruit chips, preserving flavor but often resulting in longer drying times and potential nutrient loss. Freeze drying, in contrast, utilizes low temperatures and vacuum pressure to sublimate ice directly into vapor, retaining more nutrients, texture, and flavor while producing a lightweight, shelf-stable product. Choosing between sun drying and freeze drying depends on balancing factors such as cost, drying duration, and desired product quality.

Table of Comparison

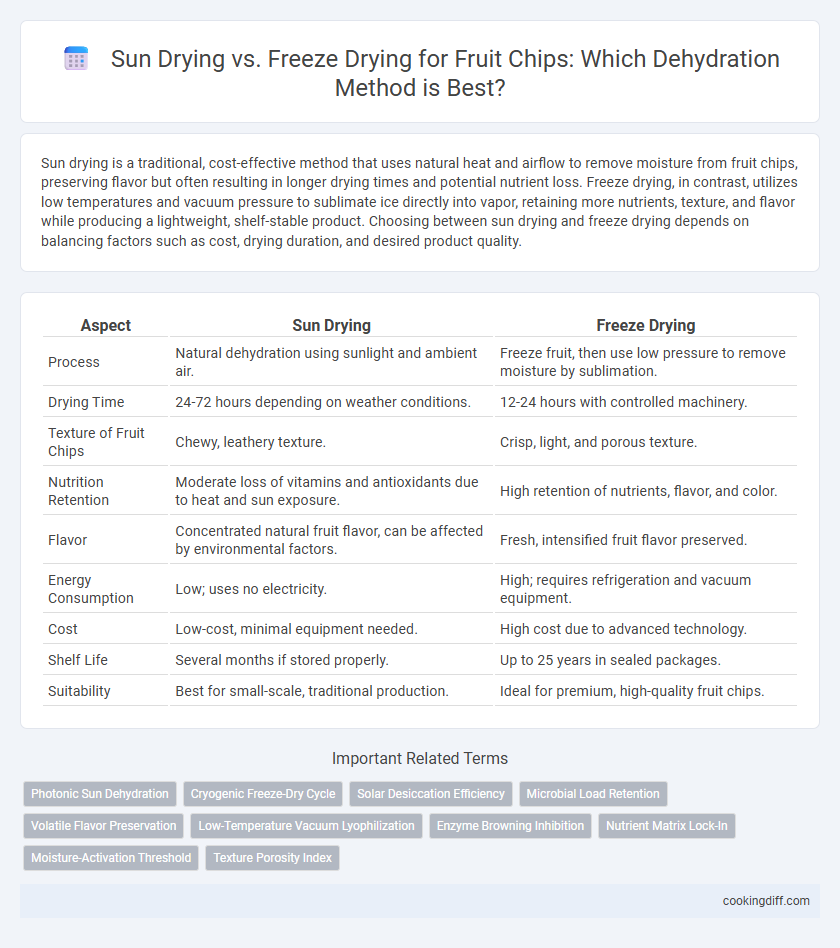

| Aspect | Sun Drying | Freeze Drying |

|---|---|---|

| Process | Natural dehydration using sunlight and ambient air. | Freeze fruit, then use low pressure to remove moisture by sublimation. |

| Drying Time | 24-72 hours depending on weather conditions. | 12-24 hours with controlled machinery. |

| Texture of Fruit Chips | Chewy, leathery texture. | Crisp, light, and porous texture. |

| Nutrition Retention | Moderate loss of vitamins and antioxidants due to heat and sun exposure. | High retention of nutrients, flavor, and color. |

| Flavor | Concentrated natural fruit flavor, can be affected by environmental factors. | Fresh, intensified fruit flavor preserved. |

| Energy Consumption | Low; uses no electricity. | High; requires refrigeration and vacuum equipment. |

| Cost | Low-cost, minimal equipment needed. | High cost due to advanced technology. |

| Shelf Life | Several months if stored properly. | Up to 25 years in sealed packages. |

| Suitability | Best for small-scale, traditional production. | Ideal for premium, high-quality fruit chips. |

Introduction to Fruit Chip Dehydration Methods

Sun drying and freeze drying are two prominent methods used to dehydrate fruit chips, each offering distinct advantages and effects on texture and nutrient retention. Choosing the appropriate dehydration method influences the shelf life, flavor, and overall quality of the final fruit chip product.

- Sun Drying - Utilizes natural sunlight to evaporate moisture, resulting in a cost-effective but slower dehydration process with moderate nutrient preservation.

- Freeze Drying - Involves freezing the fruit and then reducing surrounding pressure to remove moisture via sublimation, maintaining superior texture and high nutrient retention.

- Fruit Chip Quality - Depends on dehydration techniques that balance drying time, temperature, and method to optimize flavor, appearance, and shelf stability.

What is Sun Drying? Process and Principles

Sun drying is a natural dehydration method that removes moisture from fruit by exposing it to direct sunlight, relying on heat and air circulation to inhibit microbial growth. This traditional process preserves fruit by evaporating water content, allowing the fruit to be stored for extended periods without refrigeration.

- Exposure to Sunlight - Fruits are laid out on trays or mats under direct sunlight to absorb heat and initiate moisture evaporation.

- Air Circulation - Natural airflow aids in removing the evaporated moisture from the fruit's surface, speeding up the drying process.

- Temperature and Time Dependency - Effective sun drying requires consistent warm temperatures and can take several hours to days depending on fruit type and weather conditions.

Understanding Freeze Drying: How It Works

Freeze drying removes moisture from fruit chips by freezing them and then reducing pressure to allow the frozen water to sublimate directly from ice to vapor. This process preserves the fruit's cellular structure and nutrient content more effectively than sun drying.

- Freezing - Fruit chips are rapidly frozen to convert water into ice crystals.

- Vacuum Application - A vacuum lowers the pressure, enabling sublimation without passing through the liquid phase.

- Moisture Removal - Ice sublimates off, preserving texture, flavor, and nutritional quality.

Freeze drying results in lightweight, shelf-stable fruit chips with superior taste and preservation compared to traditional sun drying.

Comparing Nutritional Retention: Sun Drying vs Freeze Drying

Sun drying fruit chips often results in significant nutrient loss, especially vitamin C and antioxidants, due to prolonged exposure to heat and sunlight. Freeze drying preserves most nutrients, including vitamins and antioxidants, by removing moisture at low temperatures.

Freeze drying retains up to 95% of the original nutritional content, making it superior for preserving flavor and health benefits compared to sun drying. The low-temperature process minimizes enzymatic degradation and oxidation, unlike sun drying, which can cause uneven drying and nutrient depletion. Consumers seeking nutrient-rich fruit chips typically prefer freeze-dried products for their superior quality and longer shelf life.

Texture and Taste Differences in Fruit Chips

Sun drying produces fruit chips with a chewy texture and intensified natural sweetness due to slow moisture evaporation under natural heat. Freeze drying preserves the fruit's cellular structure, resulting in a crisp, airy texture while maintaining original flavor and nutrients. Taste differences are notable: sun-dried chips tend to have caramelized, richer flavors, whereas freeze-dried chips offer a more subtle, fresh fruit taste with less alteration.

Equipment and Setup: Sun Drying vs Freeze Drying

Sun drying fruit chips requires minimal equipment such as drying trays, mesh screens, and access to consistent sunlight, making it a cost-effective and low-tech method. The setup often involves outdoor space with good ventilation and protection from pests and dust.

Freeze drying involves complex machinery like freeze dryers that use vacuum and low temperatures to remove moisture while preserving texture and nutrients. This method requires controlled environments, electrical power, and higher initial investment compared to sun drying equipment.

Time Investment and Efficiency of Each Method

Which drying method is more time-efficient for producing fruit chips? Sun drying typically requires several days depending on weather conditions, making it less efficient time-wise. Freeze drying, although more energy-intensive, completes dehydration in hours, resulting in higher efficiency and consistent quality.

Cost Analysis: Which Dehydration Method is More Economical?

Sun drying requires minimal initial investment, using natural sunlight and low equipment costs, making it highly economical for small-scale fruit chip production. Freeze drying incurs significant upfront expenses due to specialized machinery and high energy consumption, increasing operational costs despite superior preservation quality. For large-scale commercial operations, solar drying offers cost-effective solutions, while freeze drying may justify the expense through higher product value and extended shelf life.

Shelf Stability and Storage Considerations

Sun drying fruit chips results in moderate shelf stability due to residual moisture content, which can encourage microbial growth if not stored properly. Proper storage requires airtight containers in cool, dry environments to prevent spoilage and maintain quality.

Freeze drying produces fruit chips with extremely low moisture content, significantly extending shelf life and enhancing shelf stability under varied storage conditions. These chips can be stored at room temperature without refrigeration, making freeze drying ideal for long-term storage and convenience.

Related Important Terms

Photonic Sun Dehydration

Photonic sun dehydration leverages solar radiation and controlled airflow to efficiently reduce moisture in fruit chips, preserving natural nutrients and enhancing flavor retention compared to traditional sun drying. This method offers a sustainable and cost-effective alternative to freeze drying, minimizing energy consumption while maintaining high product quality.

Cryogenic Freeze-Dry Cycle

Cryogenic freeze-dry cycle preserves fruit chips by rapidly freezing with liquid nitrogen, minimizing cellular damage and retaining maximum nutritional value compared to traditional sun drying. This method ensures superior texture and flavor retention while extending shelf life without the need for additives.

Solar Desiccation Efficiency

Solar desiccation efficiency in sun drying fruit chips depends heavily on factors such as sunlight intensity, ambient temperature, and humidity levels, typically achieving moisture reductions of 50-70% over several days. Freeze drying offers superior dehydration by rapidly sublimating moisture at low temperatures, preserving flavor and nutrients but requiring significantly higher energy input compared to solar desiccation.

Microbial Load Retention

Sun drying fruit chips exposes them to variable environmental conditions, increasing the risk of higher microbial load retention due to prolonged drying times and potential contamination. Freeze drying preserves fruit chips by rapidly removing moisture under low temperature and vacuum, significantly reducing microbial growth and maintaining superior microbial safety.

Volatile Flavor Preservation

Sun drying often results in significant loss of volatile flavor compounds due to prolonged exposure to heat and air, leading to diminished aroma and taste in fruit chips. Freeze drying preserves most volatile compounds by rapidly freezing and sublimating moisture under low temperatures, maintaining the original fruit's flavor profile more effectively.

Low-Temperature Vacuum Lyophilization

Low-temperature vacuum lyophilization, a key process in freeze drying, preserves fruit chips by sublimating moisture under reduced pressure and low temperatures, maintaining nutrients, flavor, and texture better than sun drying. This method significantly reduces enzymatic and microbial activity, resulting in higher quality and longer shelf life compared to the traditional sun drying technique.

Enzyme Browning Inhibition

Freeze drying effectively inhibits enzyme browning in fruit chips by rapidly freezing the fruit and reducing moisture content under vacuum, preserving color and nutrient integrity. Sun drying exposes fruit to oxygen and heat over extended periods, promoting enzymatic browning and resulting in darker, less visually appealing chips.

Nutrient Matrix Lock-In

Sun drying retains some nutrients but often results in significant degradation of vitamins like C and B-complex due to prolonged exposure to heat and UV radiation. Freeze drying preserves the nutrient matrix more effectively by sublimating water at low temperatures, maintaining the fruit chips' original antioxidant levels, enzymes, and flavor compounds.

Moisture-Activation Threshold

Sun drying fruit chips relies on natural heat and airflow but struggles to consistently reach the moisture-activation threshold necessary for optimal preservation, often resulting in uneven dehydration and potential microbial growth. Freeze drying achieves precise moisture-activation threshold control by sublimating ice under low temperatures and vacuum, preserving texture, flavor, and nutritional content with minimal enzymatic or microbial activity.

Sun Drying vs Freeze Drying for fruit chips. Infographic

cookingdiff.com

cookingdiff.com