Traditional tray dehydrators use stacked trays where air flows horizontally, often resulting in uneven drying and longer processing times for vegetable crisps. Vertical airflow dehydrators circulate air uniformly from top to bottom, ensuring consistent moisture removal and crispier textures. This efficient airflow design in vertical models enhances energy savings while preserving the vibrant color and flavor of the vegetables.

Table of Comparison

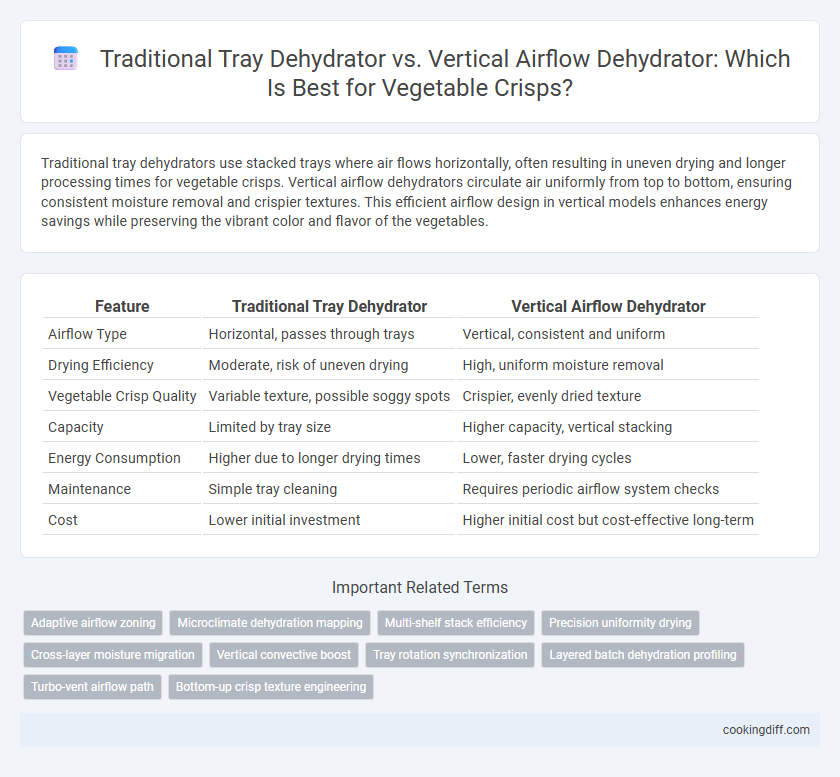

| Feature | Traditional Tray Dehydrator | Vertical Airflow Dehydrator |

|---|---|---|

| Airflow Type | Horizontal, passes through trays | Vertical, consistent and uniform |

| Drying Efficiency | Moderate, risk of uneven drying | High, uniform moisture removal |

| Vegetable Crisp Quality | Variable texture, possible soggy spots | Crispier, evenly dried texture |

| Capacity | Limited by tray size | Higher capacity, vertical stacking |

| Energy Consumption | Higher due to longer drying times | Lower, faster drying cycles |

| Maintenance | Simple tray cleaning | Requires periodic airflow system checks |

| Cost | Lower initial investment | Higher initial cost but cost-effective long-term |

Introduction to Vegetable Crisp Dehydration Methods

Traditional tray dehydrators use stacked trays with horizontal airflow, which can result in uneven drying and longer dehydration times for vegetable crisps. Vertical airflow dehydrators enhance drying efficiency by directing air vertically, promoting uniform moisture removal and preserving texture. Choosing the right method impacts the crispness, flavor retention, and overall quality of dehydrated vegetables.

Overview of Traditional Tray Dehydrators

| Traditional Tray Dehydrators | Use stacked trays where heat and air flow horizontally across each layer, suitable for small to medium batches of vegetable crisps. |

| Airflow | Relies on horizontal airflow, which can cause uneven drying if trays are overcrowded or improperly loaded. |

| Temperature Control | Typically features adjustable thermostats ranging from 95degF to 160degF, allowing precise drying for delicate vegetables. |

| Capacity | Common models have 4 to 10 trays, processing between 1 to 5 pounds of sliced vegetables per batch. |

| Advantages | More affordable and widely available, ideal for home users focusing on crisp texture retention in various vegetable types. |

Exploring Vertical Airflow Dehydrators

Vertical airflow dehydrators provide uniform heat distribution, ensuring consistent drying of vegetable crisps compared to traditional tray dehydrators. This technology minimizes drying time and preserves the nutritional quality and vibrant color of vegetables.

Exploring vertical airflow dehydrators reveals enhanced energy efficiency due to improved air circulation and reduced moisture retention. Their design allows for stacked trays, maximizing capacity without compromising airflow, which prevents sogginess and uneven drying. This makes vertical airflow dehydrators ideal for producing high-quality, crispy vegetable snacks at scale.

Heating and Air Circulation Differences

Traditional tray dehydrators use horizontal heating elements combined with passive air circulation, resulting in uneven drying and longer dehydration times for vegetable crisps. Vertical airflow dehydrators feature centralized fans that distribute heat evenly throughout multiple layers, optimizing drying efficiency and preserving crispness.

- Traditional tray heating - Heat is applied from the bottom, leading to temperature gradients across trays.

- Vertical airflow system - Heated air moves vertically through stacked trays for uniform drying.

- Air circulation impact - Vertical systems maintain consistent airflow velocity, preventing moisture buildup and enhancing crisp texture.

Efficiency and Drying Time Comparison

Traditional tray dehydrators use horizontal airflow, which often results in uneven drying and extended drying times for vegetable crisps. Vertical airflow dehydrators enhance efficiency by circulating hot air uniformly, significantly reducing drying time and producing consistently crispy results.

- Traditional Tray Efficiency - Limited airflow circulation causes slower dehydration and potential moisture retention in some areas.

- Vertical Airflow Efficiency - Designed for even heat distribution, improving energy use and speeding up the drying process.

- Drying Time Comparison - Vertical airflow dehydrators typically reduce drying time by 20-30% compared to traditional tray models.

Texture and Crispness Outcomes

Traditional tray dehydrators often produce uneven drying in vegetable crisps due to limited airflow, resulting in inconsistent texture and occasional sogginess. Their horizontal heat distribution can cause some slices to become overly dry while others remain moist.

Vertical airflow dehydrators employ a chimney effect to circulate air uniformly across all trays, enhancing crispness and creating a consistently crunchy texture in vegetable crisps. This improved airflow reduces drying time and preserves the structural integrity of the vegetables.

Energy Consumption and Cost Analysis

Traditional tray dehydrators generally consume more energy due to longer drying times and less efficient heat distribution compared to vertical airflow dehydrators. Vertical airflow dehydrators optimize airflow and heat transfer, reducing drying time and lowering overall electricity usage, resulting in cost savings. Investing in a vertical airflow dehydrator can significantly decrease both operational energy costs and production expenses for vegetable crisps.

Ease of Use and Maintenance

Traditional tray dehydrators feature stacked trays that require manual rotation and repositioning to ensure even drying, making the process more hands-on. Cleaning involves removing multiple trays, which can be time-consuming and cumbersome.

Vertical airflow dehydrators use a centralized fan to distribute heat evenly without needing tray rotation, simplifying operation and reducing supervision. Maintenance is easier with fewer removable parts and better airflow design that minimizes residue build-up.

Suitable Vegetable Types for Each Dehydrator

Which vegetables are best suited for traditional tray dehydrators versus vertical airflow dehydrators when making vegetable crisps? Traditional tray dehydrators excel with sliced vegetables like potatoes, carrots, and beets due to even, slow drying that preserves texture. Vertical airflow dehydrators perform better with leafy greens and herbs, ensuring quick, uniform dehydration without the need for flipping.

Related Important Terms

Adaptive airflow zoning

Traditional tray dehydrators use static trays that can create uneven drying zones, leading to inconsistent moisture levels in vegetable crisps. Vertical airflow dehydrators employ adaptive airflow zoning technology, directing air precisely to different sections, which ensures uniform dehydration and improved texture quality in the final product.

Microclimate dehydration mapping

Traditional tray dehydrators create uneven microclimate dehydration mapping with stagnant air pockets leading to inconsistent moisture removal in vegetable crisps. Vertical airflow dehydrators optimize microclimate control by promoting uniform air distribution, enhancing dehydration efficiency and producing crisps with consistent texture and quality.

Multi-shelf stack efficiency

Traditional tray dehydrators offer multi-shelf stacking but often suffer from uneven drying due to limited airflow between layers, impacting vegetable crisp quality. Vertical airflow dehydrators enhance multi-shelf stack efficiency by ensuring consistent air circulation across all trays, resulting in uniformly crisp vegetables and reduced drying time.

Precision uniformity drying

Traditional tray dehydrators offer basic airflow but often result in uneven drying and inconsistent moisture levels in vegetable crisps due to limited air circulation. Vertical airflow dehydrators provide precision uniformity drying by circulating air evenly across all trays, ensuring consistent texture and optimal crispness in every batch.

Cross-layer moisture migration

Traditional tray dehydrators often suffer from uneven cross-layer moisture migration, leading to inconsistent drying and potential sogginess in vegetable crisps. Vertical airflow dehydrators enhance moisture removal by promoting uniform air circulation across all layers, resulting in more consistent crispness and optimal texture.

Vertical convective boost

Vertical airflow dehydrators enhance vegetable crisps dehydration by promoting consistent air circulation and uniform moisture removal, resulting in faster drying times compared to traditional tray dehydrators. The vertical convective boost technology optimizes heat distribution and airflow velocity, preserving texture and nutrients while reducing energy consumption.

Tray rotation synchronization

Traditional tray dehydrators often lack synchronized tray rotation, leading to uneven airflow and inconsistent drying of vegetable crisps. In contrast, vertical airflow dehydrators feature precise tray rotation synchronization that ensures uniform dehydration, enhancing crisp texture and reducing drying time.

Layered batch dehydration profiling

Traditional tray dehydrators rely on horizontal airflow, causing uneven drying across layers and prolonged dehydration times for vegetable crisps. Vertical airflow dehydrators utilize consistent air distribution through stacked trays, enabling uniform dehydration profiles and quicker batch processing with enhanced crispness retention.

Turbo-vent airflow path

Traditional tray dehydrators rely on horizontal airflow that often results in uneven drying of vegetable crisps, whereas vertical airflow dehydrators utilize a turbo-vent airflow path to ensure consistent heat distribution and faster moisture evaporation. The turbo-vent design enhances airflow penetration across all trays, improving texture and preserving nutrients in vegetable crisps more efficiently than conventional models.

Traditional tray dehydrator vs Vertical airflow dehydrator for vegetable crisps Infographic

cookingdiff.com

cookingdiff.com