Oven drying offers precise temperature control and faster dehydration times, ensuring consistent texture and flavor for fruit snacks. Solar dehydration is an energy-efficient and cost-effective method that relies on natural sunlight but may result in uneven drying and longer processing times. Choosing between these methods depends on balancing quality control with sustainability and resource availability.

Table of Comparison

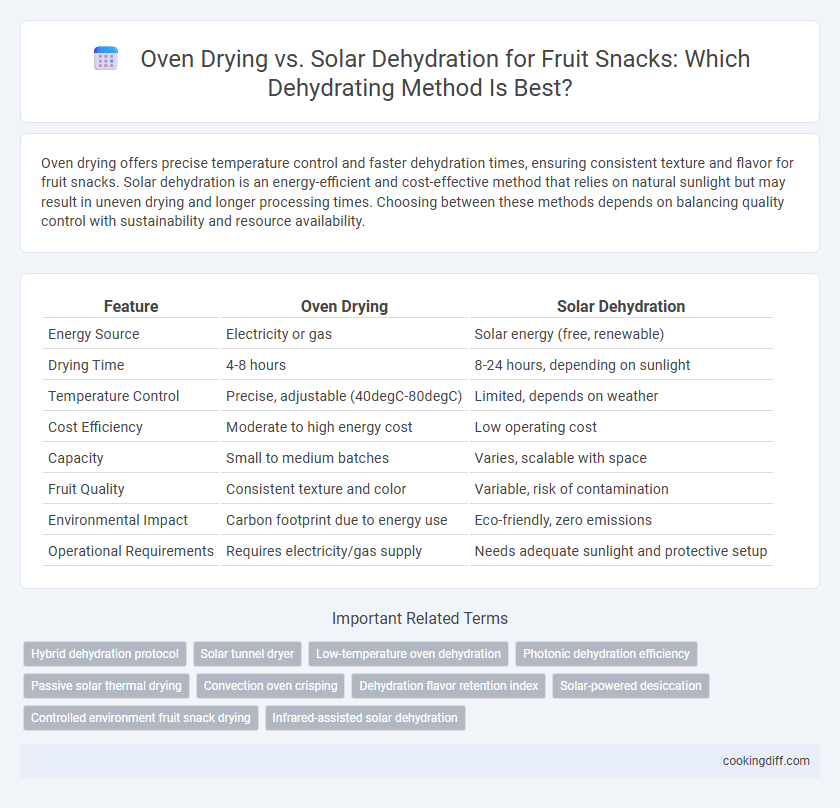

| Feature | Oven Drying | Solar Dehydration |

|---|---|---|

| Energy Source | Electricity or gas | Solar energy (free, renewable) |

| Drying Time | 4-8 hours | 8-24 hours, depending on sunlight |

| Temperature Control | Precise, adjustable (40degC-80degC) | Limited, depends on weather |

| Cost Efficiency | Moderate to high energy cost | Low operating cost |

| Capacity | Small to medium batches | Varies, scalable with space |

| Fruit Quality | Consistent texture and color | Variable, risk of contamination |

| Environmental Impact | Carbon footprint due to energy use | Eco-friendly, zero emissions |

| Operational Requirements | Requires electricity/gas supply | Needs adequate sunlight and protective setup |

Introduction to Fruit Snack Dehydration Methods

Fruit snack dehydration is an essential process to extend shelf life while preserving flavor and nutrients. Oven drying and solar dehydration are two common methods offering distinct advantages for producing dried fruit snacks.

- Oven Drying - Utilizes controlled temperature and airflow for consistent drying, resulting in uniform texture and reduced drying times.

- Solar Dehydration - Harnesses natural sunlight, making it an energy-efficient and eco-friendly dehydration method suitable for warm climates.

- Nutrient Retention - Both methods aim to minimize nutrient loss, but oven drying offers more precise control over temperature, which can better preserve vitamins.

Choosing between oven drying and solar dehydration depends on resource availability, desired product quality, and environmental considerations.

Overview of Oven Drying for Fruit Snacks

| Oven Drying | Uses controlled heat typically between 140-170degF (60-77degC) to remove moisture from fruit snacks, ensuring consistent texture and flavor preservation. |

| Drying Time | Generally requires 6-12 hours, depending on fruit type and thickness, allowing for efficient dehydration compared to natural methods. |

| Advantages | Provides precise temperature control, reduces risk of contamination, and yields a uniform product ideal for commercial and home use. |

Solar Dehydration Explained: Harnessing the Sun

Solar dehydration harnesses the sun's natural energy to dry fruit snacks, offering an eco-friendly and cost-effective alternative to oven drying. This method uses solar panels or dehydrators to convert sunlight into heat, maintaining optimal temperatures for even moisture removal and nutrient retention. Solar dehydration reduces energy consumption and preserves flavor, making it ideal for sustainable fruit snack production.

Equipment Needed: Oven vs Solar Dehydration

What equipment is essential for oven drying compared to solar dehydration when making fruit snacks? Oven drying requires an electric or gas oven with adjustable temperature settings and trays to spread the fruit evenly. Solar dehydration depends on a solar dryer or a simple solar drying rack, utilizing sunlight and airflow without electricity.

Preparation Steps for Both Methods

Oven drying fruit snacks requires slicing the fruit uniformly, arranging pieces on baking trays without overlap, and setting the oven to a low temperature around 135degF to 150degF for several hours. Solar dehydration involves washing and slicing the fruit, placing it on mesh trays inside a solar dryer or under direct sunlight with protective netting to prevent insects and debris. Both methods demand consistent monitoring to ensure even drying and prevent spoilage.

Time and Energy Consumption Comparison

Oven drying significantly reduces dehydration time compared to solar dehydration, completing the process within hours rather than days. Energy consumption in oven drying is higher due to electric or gas use, while solar dehydration relies on renewable sunlight, minimizing energy costs.

- Oven drying time - Typically takes 4-8 hours for fruit snacks, allowing faster processing and production.

- Solar dehydration duration - Requires 2-3 days dependent on weather conditions, resulting in slower turnover.

- Energy consumption comparison - Oven drying uses substantial electricity or gas, whereas solar dehydration harnesses free solar energy, reducing operational expenses.

Quality, Taste, and Texture Differences

Oven drying preserves the texture of fruit snacks by maintaining consistent heat, resulting in a chewy yet pliable product, while solar dehydration often produces a drier, more brittle texture due to variable temperature and humidity. The controlled environment of oven drying enhances flavor retention, yielding a more intense and fresh fruit taste compared to the sometimes uneven flavor profile from solar dehydration.

Oven drying typically ensures higher quality by reducing contamination risks and providing uniform drying, crucial for preserving nutrient content and visual appeal. Solar dehydration, though energy-efficient and eco-friendly, may lead to uneven drying and reduced shelf life, impacting overall product quality and consumer acceptance.

Nutritional Impact of Oven vs Solar Dehydration

Oven drying fruit snacks typically retains higher levels of nutrients such as vitamin C and antioxidants due to controlled temperature and shorter dehydration times. Solar dehydration, while energy-efficient, often leads to greater nutrient loss because of prolonged exposure to varying temperatures and sunlight.

Nutritional degradation in solar dehydration results from oxidative stress and enzymatic activity accelerated by inconsistent heat and UV radiation. Oven drying's consistent temperature around 60-70degC minimizes enzymatic reactions and preserves essential vitamins and phytochemicals. Choosing oven drying can enhance the nutritional quality and shelf life of fruit snacks, crucial for health-conscious consumers.

Cost Efficiency and Environmental Considerations

Oven drying fruit snacks typically involves higher energy costs due to electricity or gas consumption, making it less cost-efficient for large-scale production compared to solar dehydration. Solar dehydration utilizes free solar energy, significantly reducing operational expenses and making it a budget-friendly option for small farms and artisanal producers.

From an environmental perspective, solar dehydration produces zero carbon emissions during the drying process, aligning with sustainable and eco-friendly practices. Oven drying relies on fossil fuels or electricity, contributing to greenhouse gas emissions and a larger carbon footprint in fruit snack production.

Related Important Terms

Hybrid dehydration protocol

Hybrid dehydration protocols combine oven drying and solar dehydration to optimize energy efficiency and preserve nutrient content in fruit snacks. This method leverages controlled oven temperatures to ensure consistent moisture removal while utilizing solar energy to reduce operational costs and environmental impact.

Solar tunnel dryer

Solar tunnel dryers harness controlled solar energy to efficiently dehydrate fruit snacks, preserving nutritional content and flavor better than conventional oven drying methods. These dryers reduce energy costs and environmental impact while maintaining consistent temperature and airflow for uniform drying.

Low-temperature oven dehydration

Low-temperature oven dehydration effectively preserves the color, flavor, and nutritional value of fruit snacks by maintaining temperatures between 50degC and 60degC, minimizing enzymatic degradation. This method offers consistent drying conditions and faster processing times compared to solar dehydration, which is subject to variable sunlight and ambient temperatures.

Photonic dehydration efficiency

Oven drying uses consistent high temperatures around 60-70degC, providing reliable photonic dehydration efficiency by evenly removing moisture through controlled heat application, which reduces drying time and preserves fruit quality. Solar dehydration relies on natural sunlight and ambient conditions, resulting in variable photonic energy absorption and longer drying periods, but offers energy-efficient and eco-friendly dehydration with lower operational costs.

Passive solar thermal drying

Passive solar thermal drying in fruit snack dehydration offers energy-efficient temperature control by harnessing natural sunlight through greenhouse-like structures, resulting in consistent drying without external power sources. This method reduces operational costs and preserves nutrient quality compared to conventional oven drying, which relies on electricity or gas for heat generation.

Convection oven crisping

Convection oven drying provides consistent heat circulation that ensures uniform moisture removal and crisps fruit snacks more effectively than solar dehydration, which depends on variable sunlight and ambient conditions. This controlled environment in convection ovens enhances texture and flavor retention, making it a preferred method for commercial-scale fruit snack production.

Dehydration flavor retention index

Oven drying achieves a higher Dehydration Flavor Retention Index of approximately 85%, preserving more volatile compounds and natural sugars in fruit snacks compared to solar dehydration, which averages around 70% due to prolonged exposure to varying temperatures and UV light. Enhanced control over temperature and humidity in oven drying minimizes enzymatic reactions and Maillard browning, optimizing flavor preservation during dehydration.

Solar-powered desiccation

Solar-powered desiccation utilizes renewable energy to efficiently remove moisture from fruit snacks, preserving nutrients and extending shelf life without the carbon footprint associated with electric ovens. This eco-friendly method offers cost-effective dehydration, particularly in sunny regions, by harnessing natural sunlight to achieve optimal drying temperatures.

Controlled environment fruit snack drying

Oven drying provides a controlled environment with consistent temperature and humidity levels, ensuring uniform dehydration and optimal preservation of fruit snacks' flavor and nutrients. Solar dehydration, while more energy-efficient and eco-friendly, often faces variability in drying conditions, leading to uneven moisture removal and potential quality inconsistencies in the final product.

Oven drying vs Solar dehydration for fruit snacks. Infographic

cookingdiff.com

cookingdiff.com